Stock Torsion Springs - More Than 900 Designs

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Stock Torsion Springs Definition -

Helical coils are wound tightly, one after the other, to expel a radial force. A force is exerted on the stock torsion spring's leg creating a radial force. This rotational force is called torque or rate per degree. Stock torsion springs offer a variety of physical dimensions, therefore the range in force, torque, and travel is limitless.

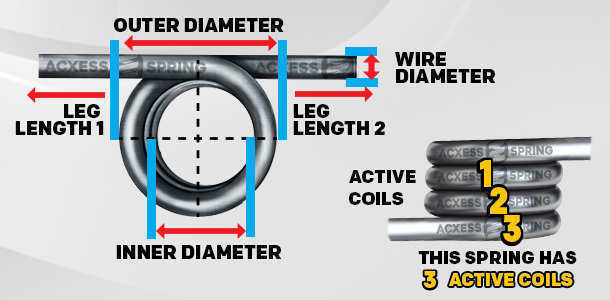

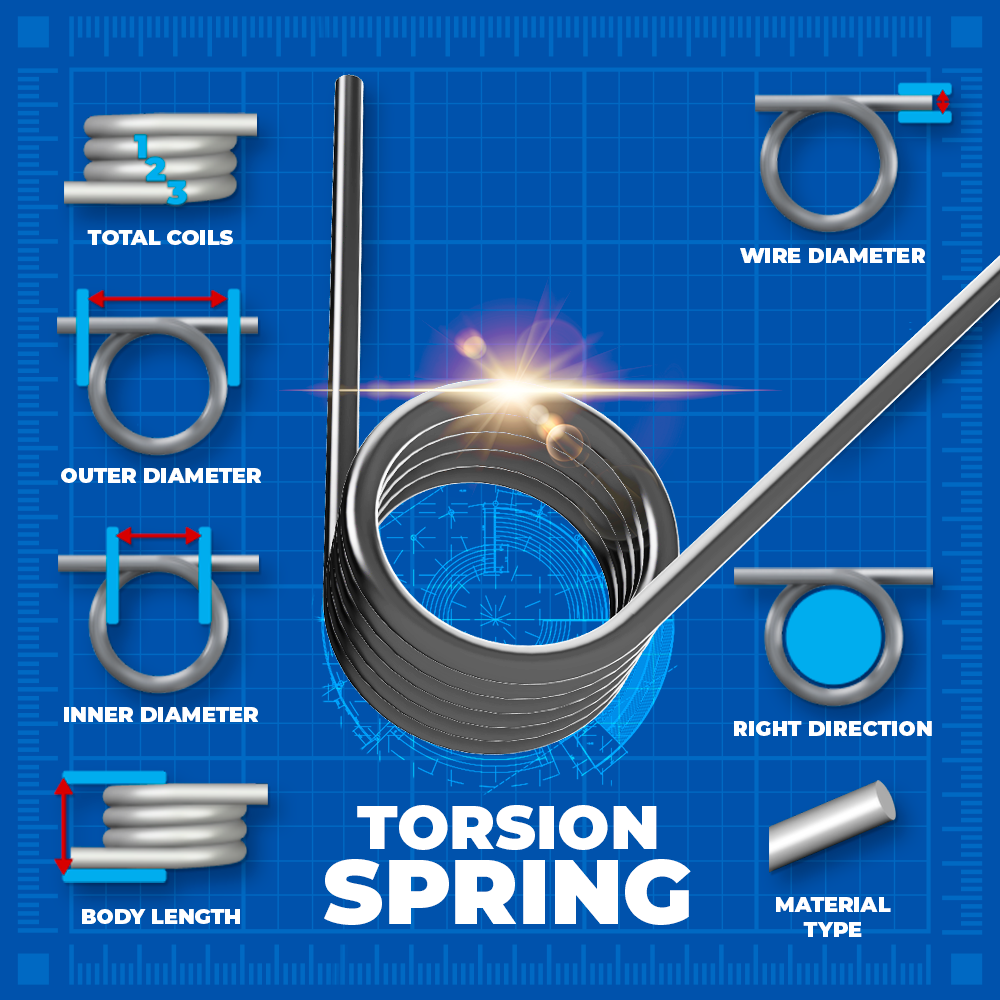

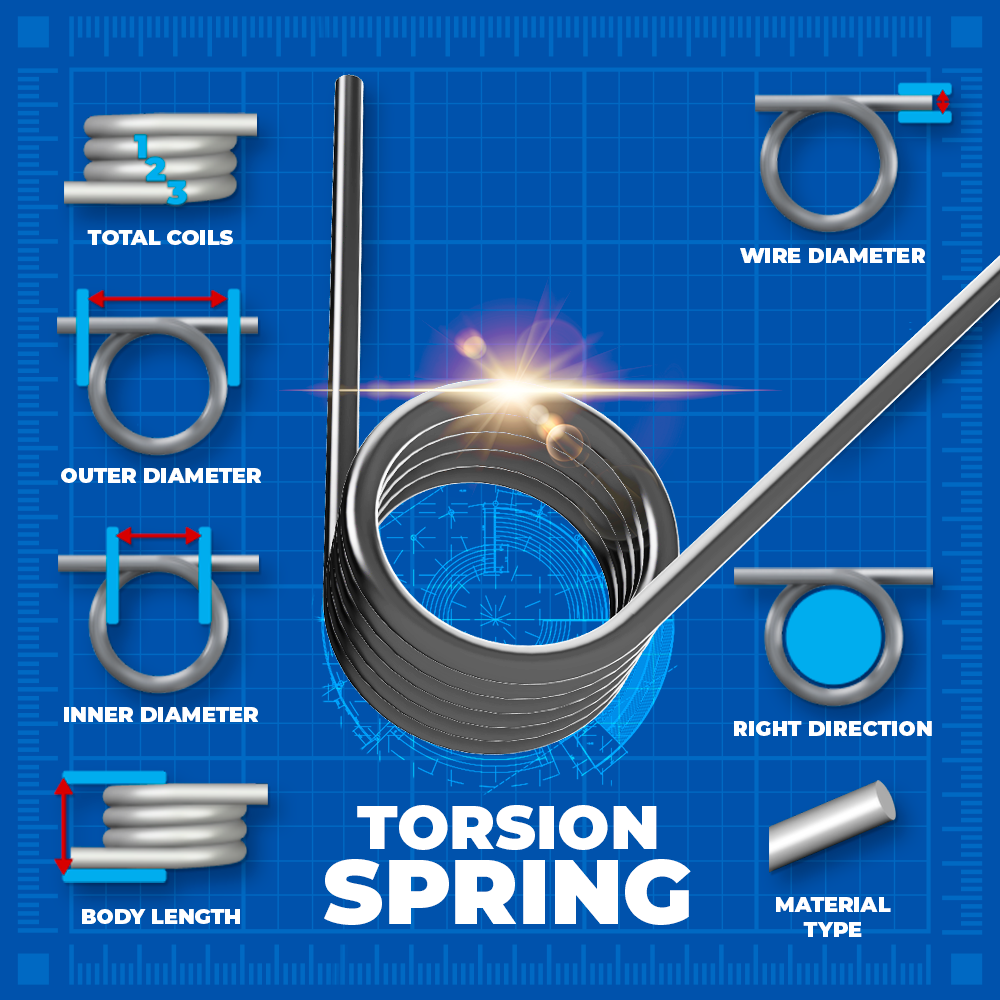

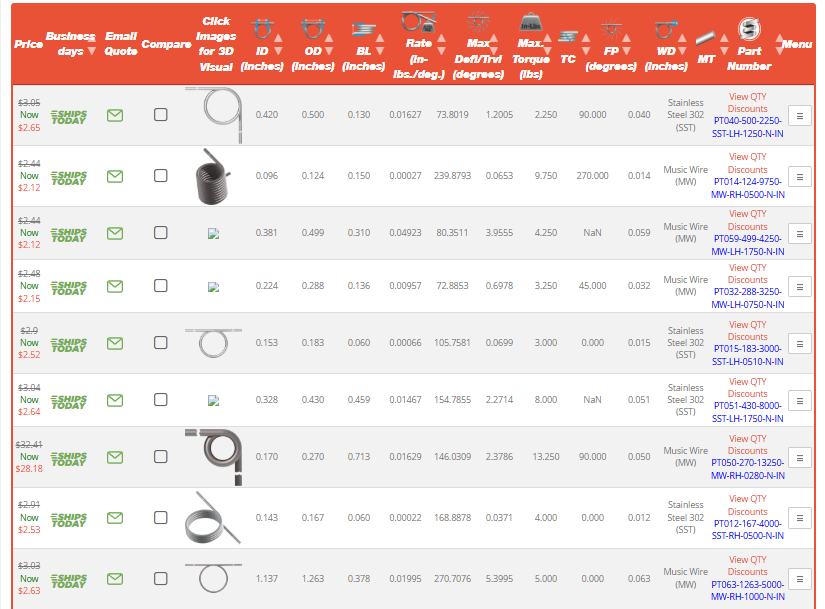

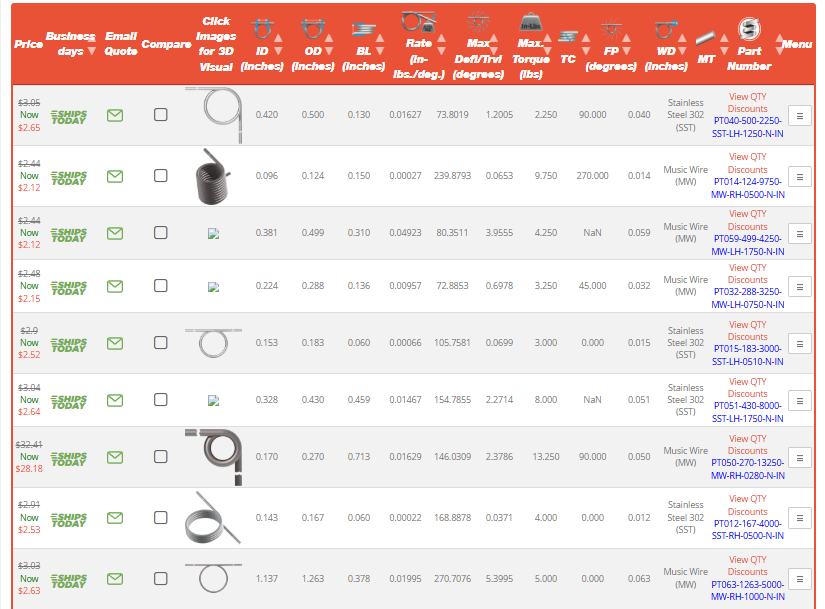

The Spring Store by Acxess Spring offers almost 1,000 different stock torsion springs which you may search through using our Online Stock Torsion Spring Finder. To do a basic search through our stock torsion spring catalog, you will only need to know your torsion spring's outer diameter (or inner diameter) and total number of coils. These measurements may be entered either in the english or metric systems. In case that you are more familiar with your torsion spring design, you may also do an advanced search where you are additionally able to input one of the following to narrow down your search:

- -Direction of Wind

- -Material Type

- -Wire Diameter

- -Body Length

- -Leg Lengths 1 and 2

- -Desired Deflection

- -Rate or Torque

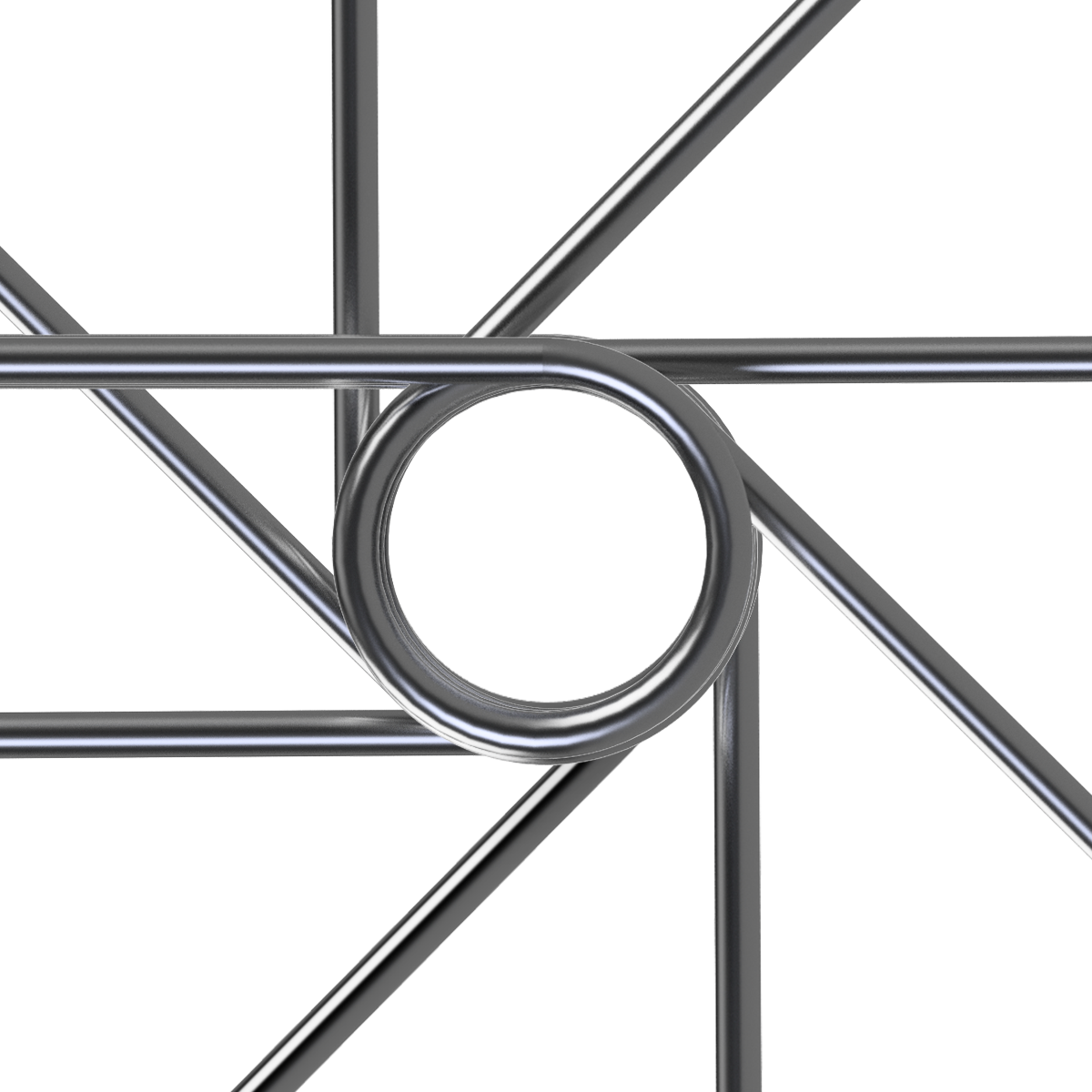

For information on how to measure your torsion spring and how to distinguish certain torsion spring dimensions, please see the diagram below.

How to Measure Your Stock Torsion Spring

In The Spring Store, customers also have access to our famous online stock torsion spring calculator tool, "Torsion Spring Creator". Our free online torsion spring calculator offers real-time blueprints of your spring along with accurate full spring analyses. Here you may work everything that has to do with your torsion spring design from physical dimensions to load, rate, and travel; including warnings and helpful tips to improve your torsion spring's functionality.

For testing and prototyping, purchasing stock torsion springs is your best option. This is because running a small batch of several different torsion springs implies several manufacturing set ups. Therefore, several manufacturing set up charges will be added to the quote. When buying stock torsion springs at The Spring Store, you may buy small quantities of several torsion springs without the additional manufacturing set up fee, making this a more economical way of purchasing your stock torsion springs

In Case that you may find several stock torsion springs that may work in your application but don't know which one to purchase, you may compare them by clicking on the "Add to Compare" button and these items will be added to the "Compare Products" section at the bottom of your screen. Once the items are at the "Compare Products" section, simply click on the option and your torsion springs' information will come up side by side for you to get a cleaner comparison of them.

We also offer several additional characteristics to our stock torsion springs which include the variations of material (or wire) types. Material types include Music Wire (Spring Steel), Hard Drawn Wire, or Stainless Steel 302 wire.

At the top our spring finder page you will find the option to look at our entire stock torsion spring catalog through our site. There, you will also find the option to download the full stock torsion springs catalogue in pdf format for your reference and perhaps a better view of what The Spring Store by Acxess Spring has to offer.

Enhance your projects with Spring Creator 5.0

Precision is crucial in spring design, and with Spring Creator 5.0, you can achieve it with ease. Our tool allows you to design different types of springs and offers advanced features such as instant quotes and real-time simulations with the Online Spring Force Tester. Register now and access all the benefits of our platform. Create the perfect spring and take your projects to the next level!

Created by Alfonso Jaramillo Jr

President Acxess Spring

Over 40 Years of Experience in Spring Engineering and Manufacturing

Stock Torsion Springs

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Table of Contents

What is a Torsion Spring?

A torsion spring is a helical coil that stores mechanical energy when twisted. Unlike compression or extension springs, which push or pull in a straight line, torsion springs exert rotational force (or torque). When their legs are deflected—bent around a central axis—they generate torque that tries to return them to their original position. This makes them indispensable in applications that require parts to rotate back, hold a hinged position, or maintain controlled angular movement.

Now, why go with a stock torsion spring?

The answer is speed, cost-efficiency, and simplicity. Stock springs are pre-manufactured, standardized components that are kept in inventory and ready to ship. That means you can find what you need fast, often at a fraction of the price of a custom part. Whether you're prototyping a new mechanism, repairing an existing device, or engineering on a tight schedule, a stock torsion spring allows you to move quickly without compromising on quality or performance.

How Torsion Springs Work?

Think of a torsion spring as the muscle behind the twist. Instead of pushing or pulling like a typical spring, a torsion spring works by twisting—and in doing so, it creates a rotational force called torque.

Here’s the simplest way to picture it: Have you ever used a clothespin? When you squeeze the ends open, you’re actually twisting a spring in the middle. As soon as you let go, that spring wants to snap back—that’s torque in action. The same principle applies to many other items: laptop hinges, clipboards, garage doors, even mousetraps.

A torsion spring is a tightly wound coil with two arms, or “legs.” When you rotate those legs (either clockwise or counterclockwise), you twist the coils tighter. The spring stores that energy and pushes back, trying to return to its original shape. That pushback is what makes things close automatically, lock into place, or return to a starting position.

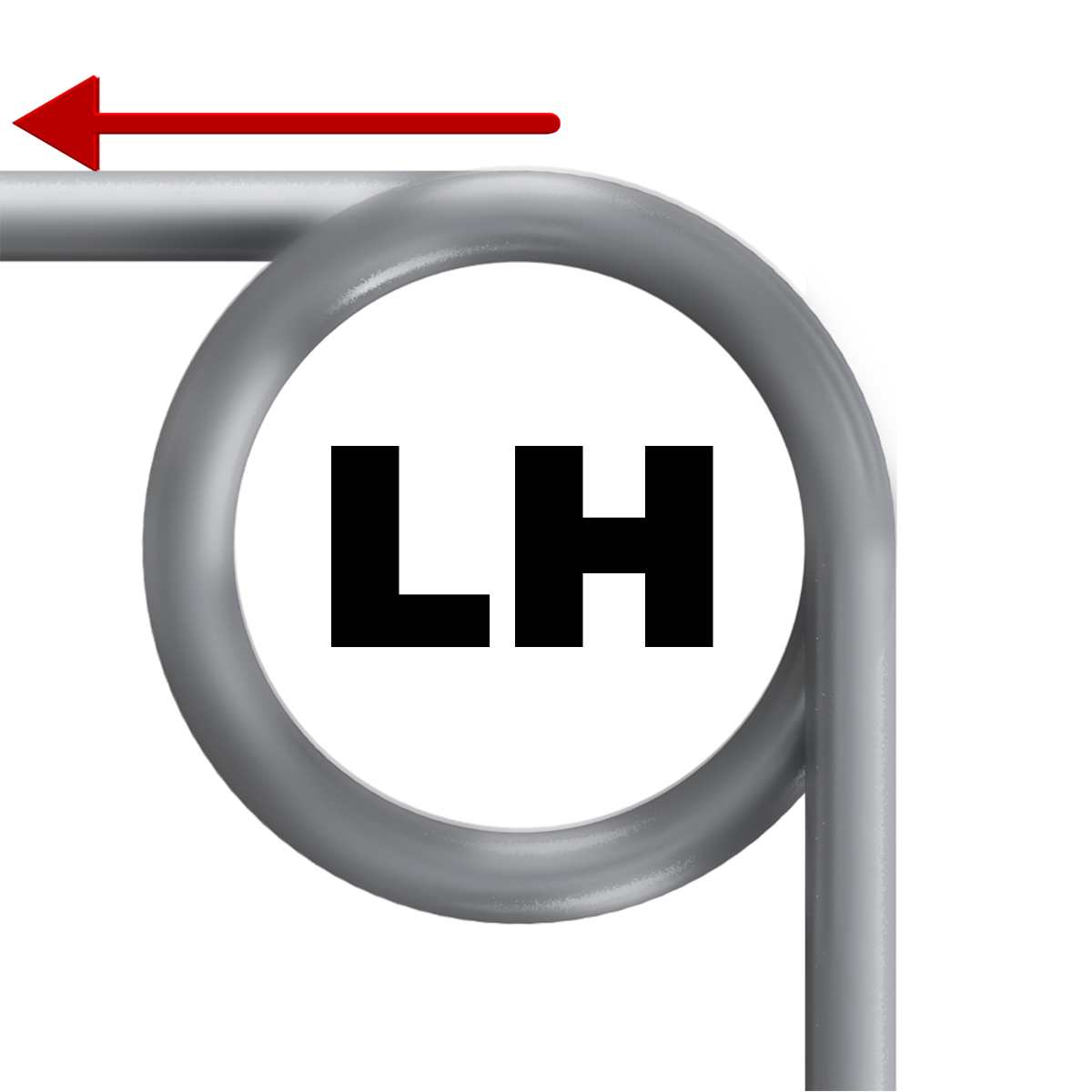

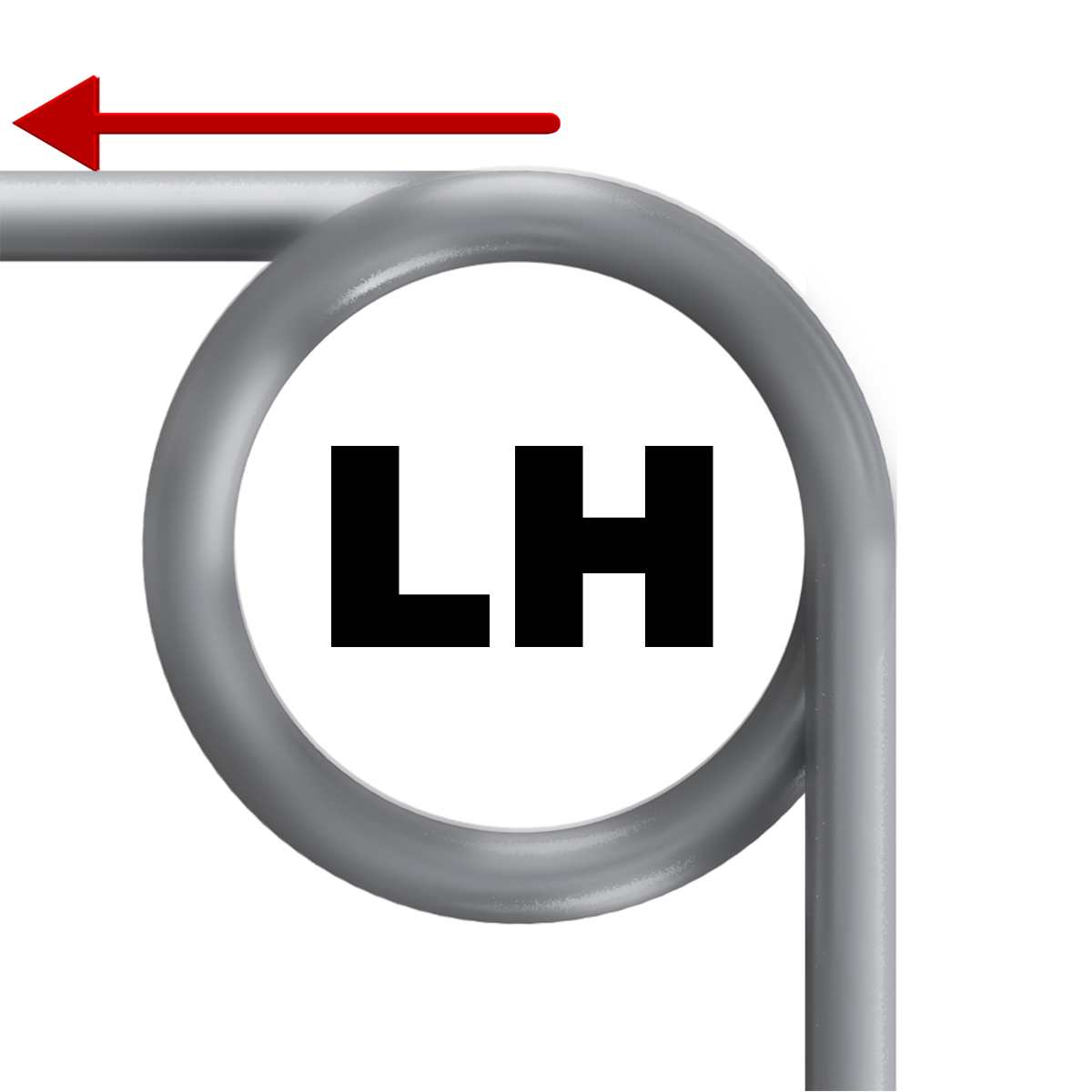

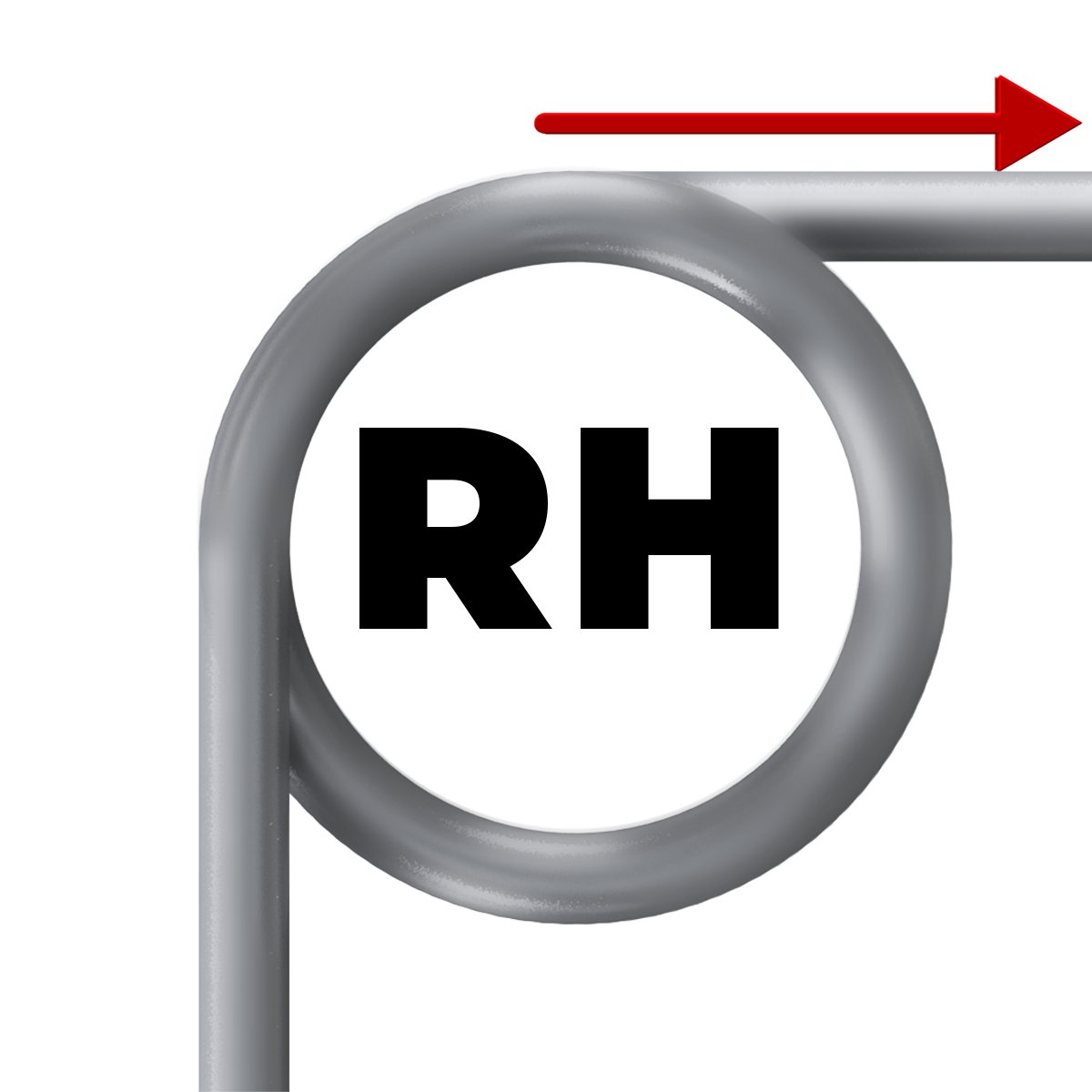

Direction Matters: Right-Hand vs. Left-Hand Wind

When working with torsion springs, one detail that trips up even seasoned engineers is winding direction. It's a small thing—but it makes a big difference.

Torsion springs come in two winding types:

-

Right-hand wound: These springs are twisted tighter counterclockwise when viewed from the end.

-

Left-hand wound: These springs are twisted tighter clockwise when viewed from the end.

???? Why does this matter?

Because torsion springs only work well when you load them in the correct direction—the one that makes the coils tighten, not loosen. If you apply torque the wrong way, the spring can deform, fail, or even snap.

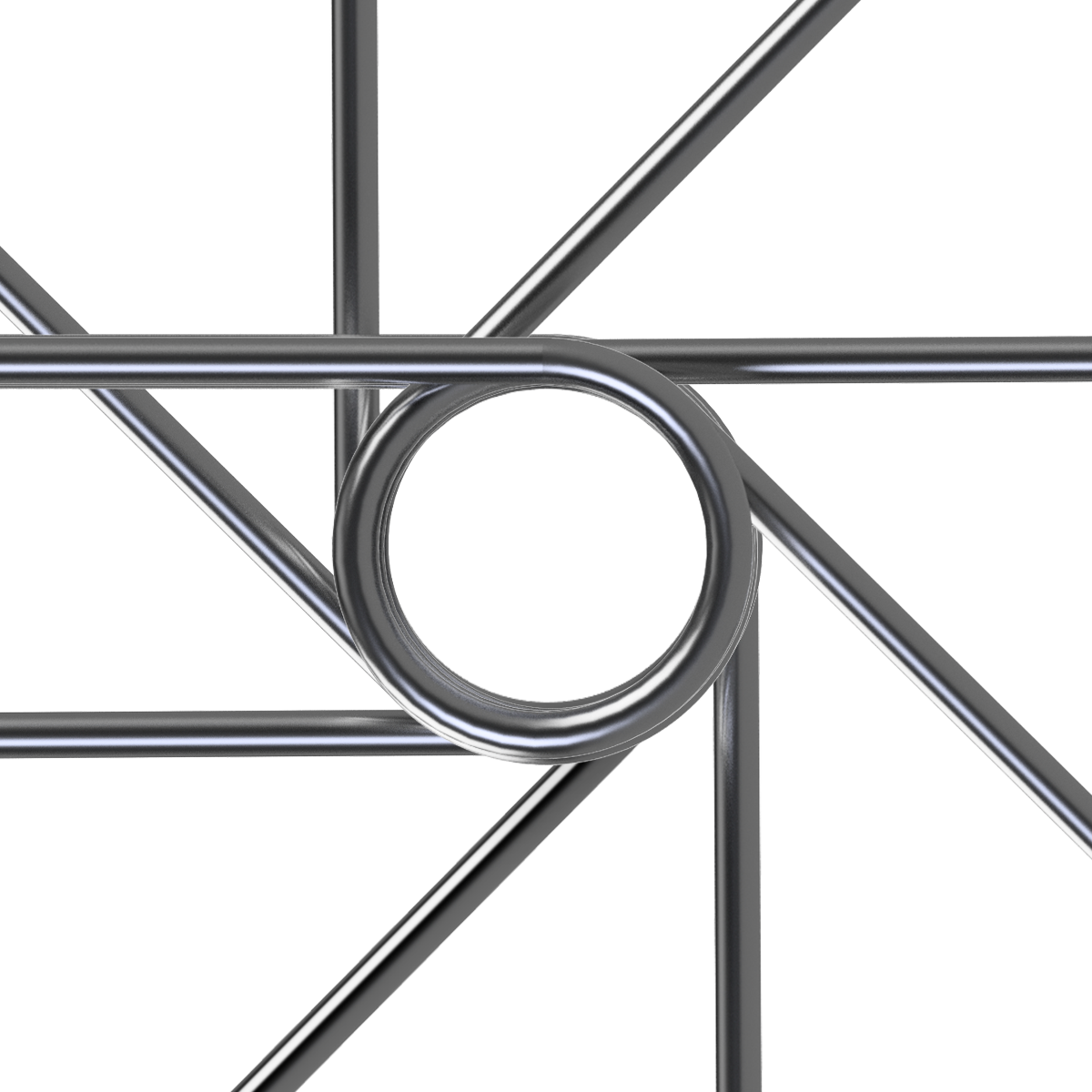

What Holds the Spring in Place?

Torsion springs usually sit on a rod or inside a hole that keeps the coil from shifting. The legs are connected to different parts of your mechanism—one part stays still, and the other moves. As the moving part rotates, it twists the spring and builds torque, which then helps return or hold that position.

How to Measure Torsion Springs?

Whether you’re replacing a broken spring or ordering a new one, measuring a torsion spring accurately is crucial. These springs may look simple, but every small dimension affects how they perform—so the more precise you are, the better your chances of finding the right match or designing one that works.

Don’t worry—you don’t need to be an engineer to get it right. Just follow this step-by-step guide and use a ruler or, even better, a digital caliper for accuracy.

???? What You’ll Need:

-

A digital caliper (recommended) or a fine ruler

-

A flat surface and good lighting

-

A notepad or phone to record measurements

- Your original spring (even if broken—just be careful)

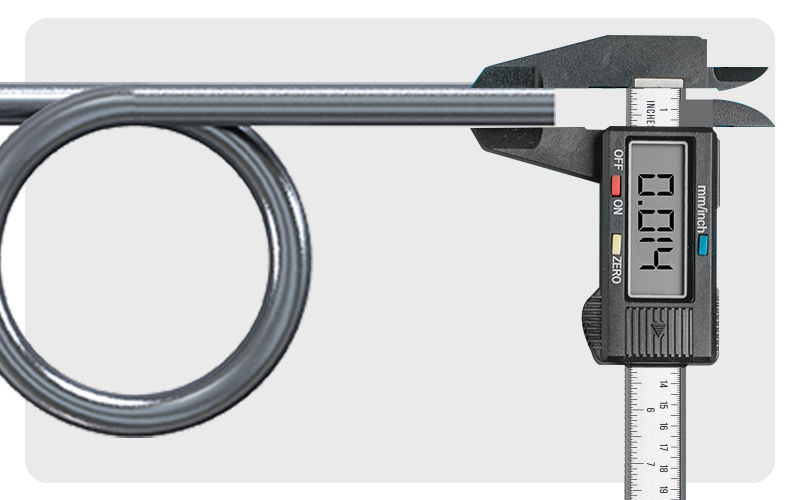

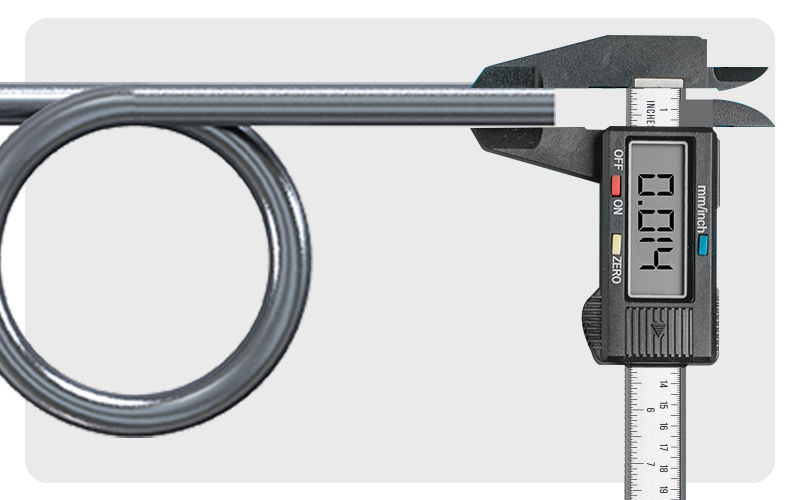

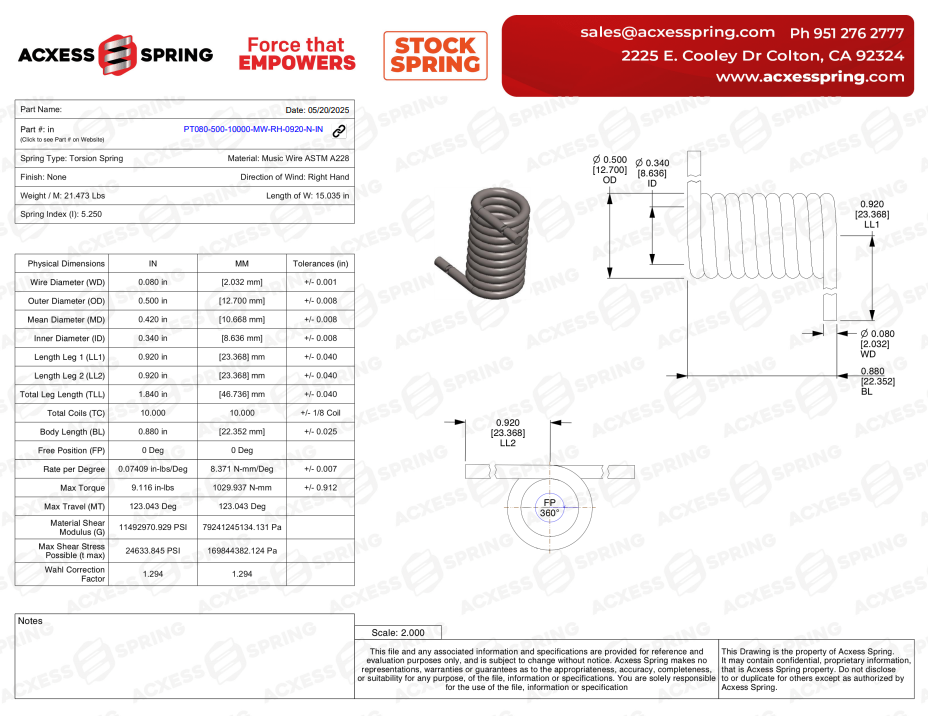

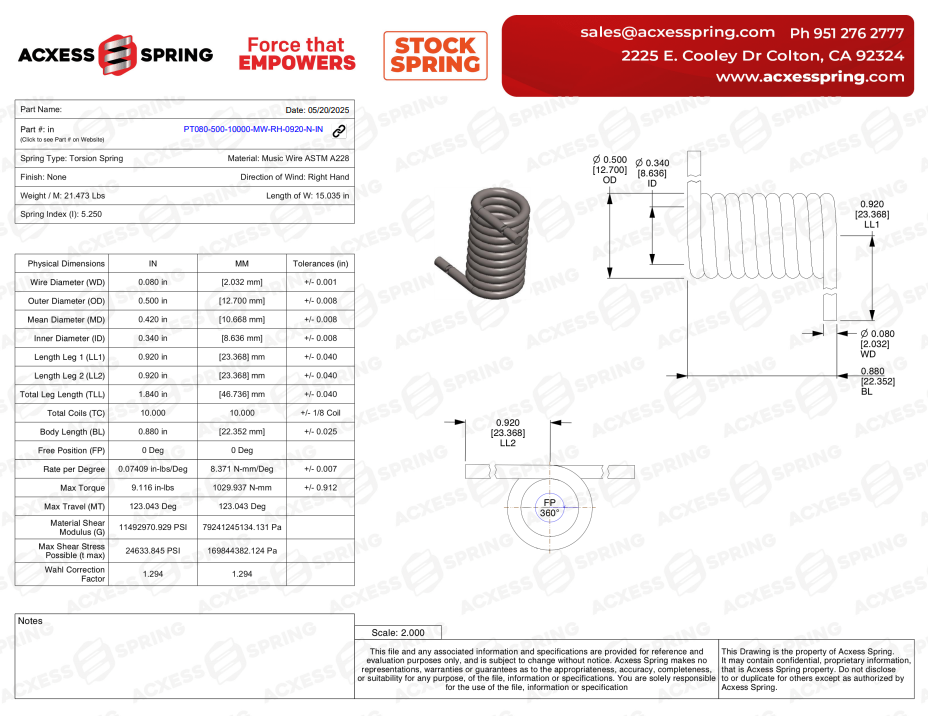

1. Wire Diameter (How thick is the spring wire?)

This is the thickness of the wire used to make the coils. It directly affects how strong the spring is and how much torque it can handle.

-

How to measure it: Place your caliper across the wire itself—not across the whole spring. Measure in a few spots and average the values if needed.

-

Example: You measure 0.080 inches (about 2.032 mm).

This tells you what wire size to look for when browsing stock options.

???? Tip: Don’t guess based on appearance. A difference of just 0.005" can change the spring’s strength by a lot.

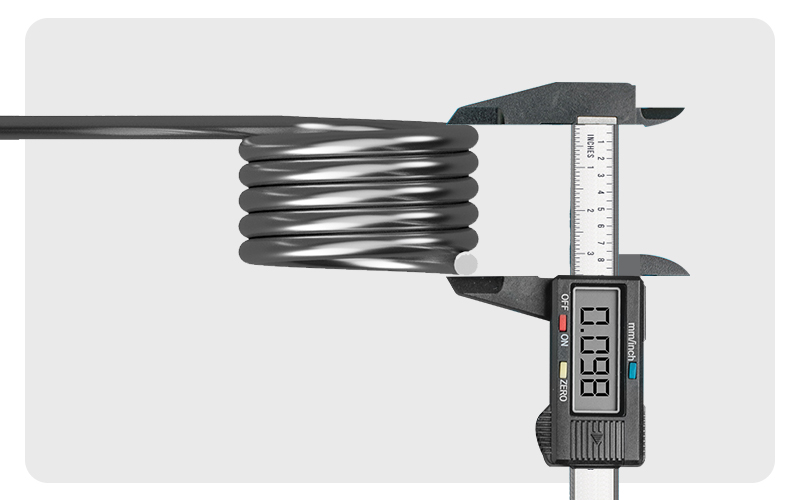

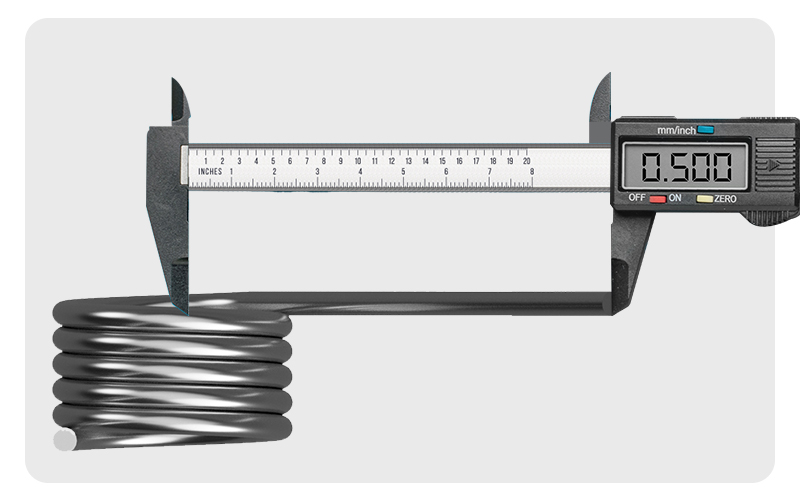

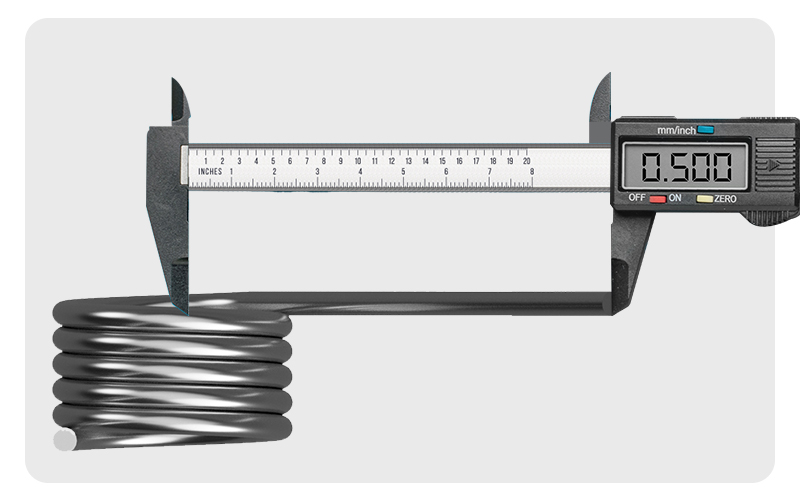

2. Outer Diameter (OD) – How wide is the spring from edge to edge?

This is the full width of the spring coil. It tells you whether the spring will fit inside a housing or slide over a shaft.

-

How to measure it: Place calipers or a ruler across the widest part of the coil—from one outside edge to the other.

-

Example: Your spring measures 0.500 inches (or 12.70 mm) across.

???? Important: If your spring needs to sit inside a tube or fit over a rod, this number must be exact.

3. Inner Diameter (ID) – How wide is the hole inside the spring?

This is the size of the hole down the center of the coil. It’s important if your spring goes around a rod or shaft.

-

How to find it: If you can't measure it directly, subtract twice the wire diameter from the outer diameter:

ID = OD - 2 × Wire Diameter -

Example:

0.500" OD – 2 × 0.080" wire = 0.340" ID (or 8.636 mm)

???? Make sure the ID is slightly larger than the rod it will sit on—leave a little clearance.

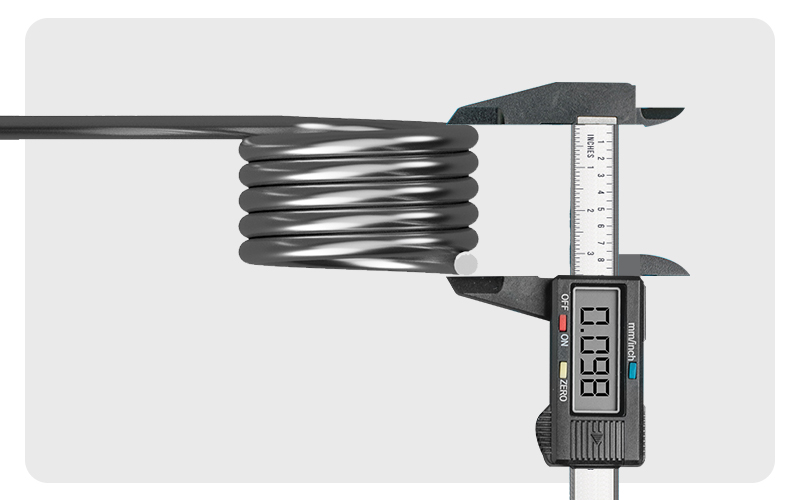

4. Body Length – How tall is the coiled section?

This is the length of the spring’s coiled part, not counting the legs (arms). It helps you figure out how much axial space the spring will take up in your mechanism.

-

How to measure it: Lay the spring on its side and measure from one end of the coil stack to the other.

-

Example: The coil section is 0.880 inches (about 22.352 mm) long.

???? This is important when space is tight in your device or housing.

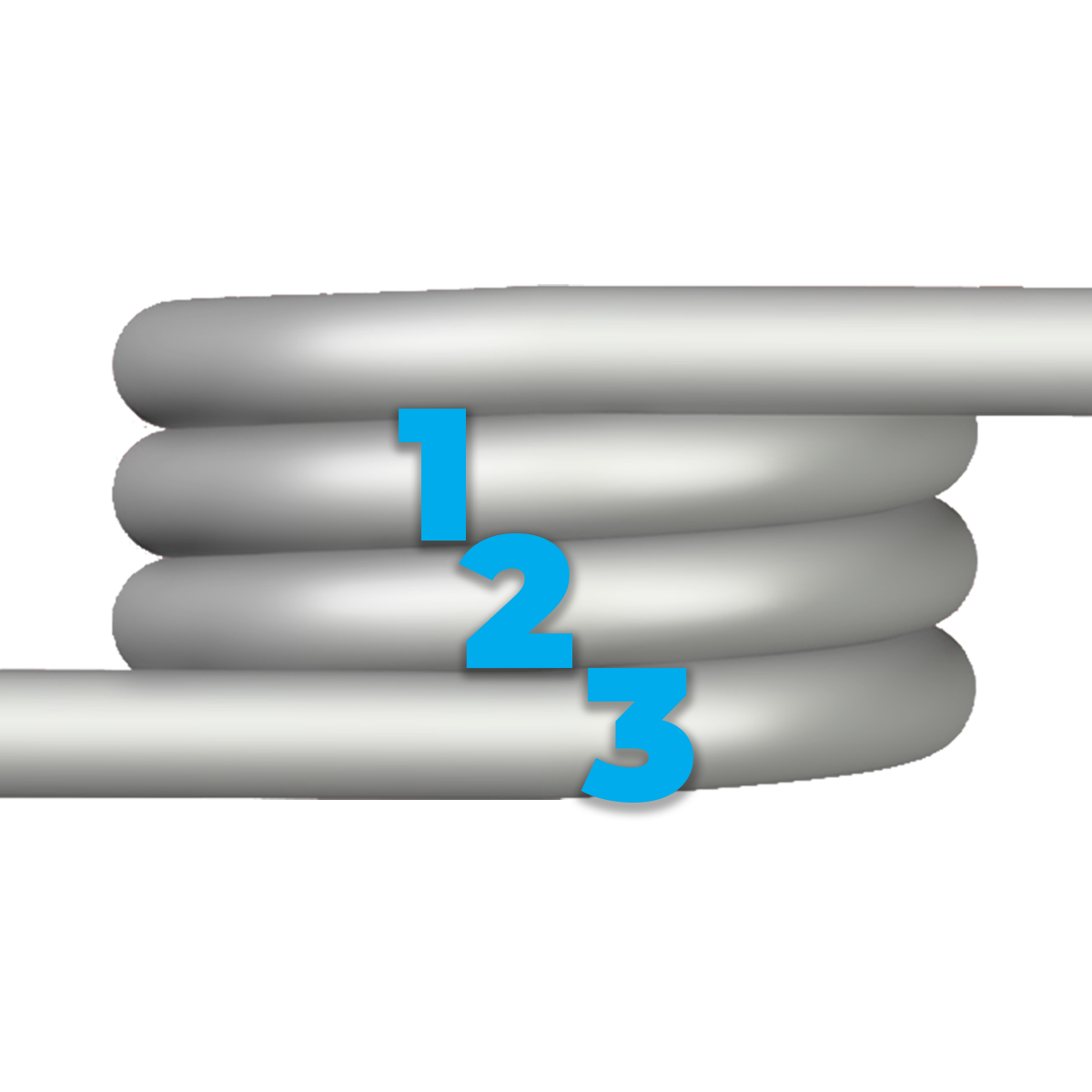

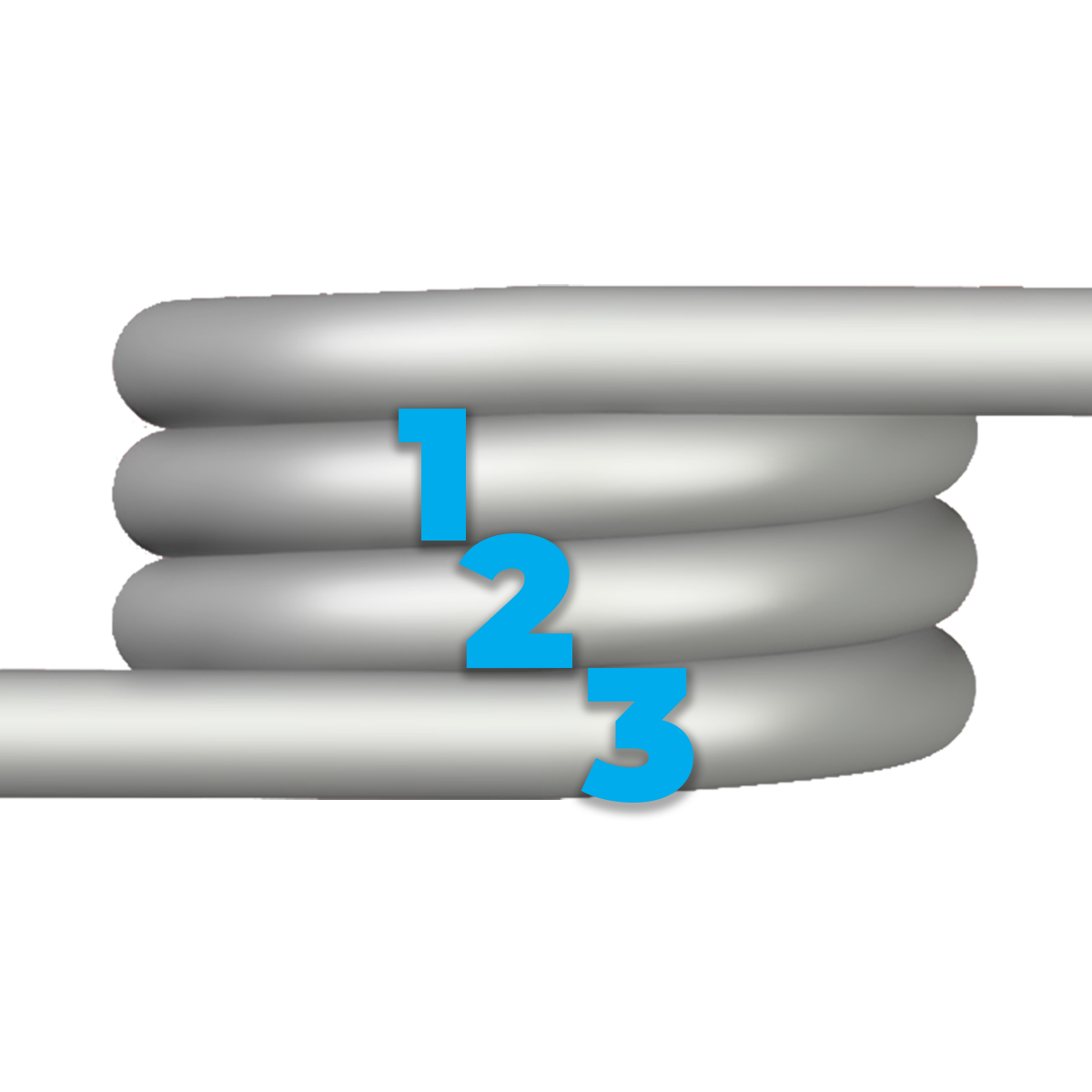

5. Total Coils – How many full loops?

The number of coils affects how much the spring can twist and how much torque it can produce.

-

How to count: Look closely and count each full loop of wire. If one leg wraps partway around, include it as a partial coil (e.g., 4.5 coils).

-

Example: You count 10 full coils with no partial coils, which is 10 coils total.

???? More coils generally means more flexibility (longer travel), but less torque.

6. Leg Lengths – How long are the spring’s arms?

Torsion springs usually have two legs that stick out from the coil. Their length affects how and where the spring attaches to your mechanism.

-

How to measure: Measure from the center of the coil out to the tip of the leg. If that’s tricky, measure from the coil’s edge and add half of the outer diameter.

-

Example:

From edge to leg tip = 0.67"

Half OD = 0.25"

Total leg length ≈ 0.67" + 0.25" = 0.920 inches (23.368 mm)

✏️ If one leg is longer than the other, measure both and record each one.

7. Free Position– What’s the angle between the legs?

This tells you the position of the legs when the spring is at rest. It’s measured in degrees: common values are 90°, 180°, 270°, and 360°.

-

How to measure: Lay the spring flat. Imagine or draw a line from the center of the coil through each leg. Use a protractor or angle template to find the angle between the legs.

-

Example: If both legs form a straight line, lying flat along a surface, that’s a 0° angle. This means there’s no gap between the legs in the spring’s relaxed position—they're aligned.

???? This affects how far the spring can twist and how it fits into your assembly.

8. Winding Direction – Left-hand or Right-hand?

This is one of the most important measurements, especially if you're replacing a spring.

-

How to tell: consider how the spring twist during use:

-

If it twists counterclockwise to store energy → Right-hand wind

-

-

If it twists clockwise to store energy → Left-hand wind

↪️ Springs are designed to be twisted in the direction that tightens them. Loading a spring the wrong way can cause it to fail.

Example Measurement Set

Here’s what your notes might look like after measuring a spring:

|

Measurements |

|

|---|---|

|

Wire Diameter |

0.080" (2.032 mm) |

|

Outer Diameter |

0.500" (12.70 mm) |

|

Body Length |

0.880" (22.352 mm) |

|

Total Coils |

10 |

|

Leg 1 Length |

0.920" (23.368 mm) |

|

Leg 2 Length |

0.920" (23.368 mm) |

|

Leg Angle |

0° |

|

Wind Direction |

Right-hand |

Once you have this info, you can:

✅ Search for a stock spring at The Spring Store

✅ Plug the specs into Spring Creator 5.0 to design your own spring

✅ Send the measurements to Acxess Spring if you need help selecting the best option

After measuring and determining the specs you need, the next step might be to find a ready-made (stock) spring that meets your requirements. Searching through several catalogs for a torsion spring that matched your measurements, you’ll find an exact fit in Acxess Spring’s stock selection: Part Number PT080-500-10000-MW-RH-0920-N-IN. This off-the-shelf option saved time and removed the guesswork, perfectly matching the dimensions needed—no custom lead time needed.

Where to Buy Stock Torsion Springs?

Fortunately, torsion springs are common components, and many suppliers offer stock torsion springs in a variety of sizes. Purchasing a stock spring is often faster and cheaper than having one custom-made, provided you can find a close match. Here are some tips on where to look and specifically how to use Acxess Spring’s catalogs as a resource:

- Using Online Catalogs and Finders: On The Spring Store, you can navigate to the torsion spring stock catalog section. We provide an online spring finder tool where you can plug in your known dimensions. For instance, you can enter your measured outer diameter, number of total coils, wire diameter, free position, etc., and the tool will filter the catalog to show springs that meet those parameters. You can search in either English or metric units. There is also an option for a basic search (just a couple of inputs like OD and coils) or an advanced search where you can refine with more details (max torque, rate, leg length, material, etc.). The interface is user-friendly – in just a few clicks, you get a list of part numbers that match your needs. Each spring listing will usually include all the specifications so you can verify it matches what you measured.

-

Acxess Spring’s PDF Stock Catalog: Not only can you search online, but you can also download the full stock spring catalog PDF. Having the PDF is handy if you want to browse or compare multiple springs side by side. The catalog will list each spring’s dimensions, material (music wire, stainless, etc.), maximum torque, and a part number. You can use that part number to order directly.

Buying stock torsion springs is as easy as searching an online catalog with your measurements. Always verify the key specs of the chosen spring against your needs (especially torque capacity and fit). If you’re ever unsure, don’t hesitate to reach out to our customer support.

How Long Do Torsion Springs Last?

The good news is: a well-designed torsion spring can last for years—or even decades. The not-so-good news? If the wrong spring is used, or it’s pushed too hard, it could wear out in weeks. Each full twist and return is called a cycle, and most springs are rated for 10,000 cycles or more. That might sound like a lot, but in daily use, it adds up fast. Factors like how far the spring is twisted, the material (stainless steel for corrosion resistance or music wire for strength), the environment (humidity, heat, vibration), and installation quality all affect lifespan. A well-supported spring, mounted on a shaft, operating within 75–85% of its max deflection, will last significantly longer than one that’s overloaded or misaligned. For example: If you open a storage box lid just twice a day, that adds up to 730 cycles per year. With a spring rated for 10,000 cycles, it could easily last over 13 years with normal use. And because smaller springs are often under less stress and used in gentler applications, they tend to last even longer—especially if they're well-installed and protected from rust.

To extend spring life, avoid overstressing it, choose the right material for your conditions, and keep it protected from rust and impact. Lubrication can help reduce wear, and proper leg support prevents uneven loading. For high-cycle or industrial applications, consider springs with higher cycle ratings or surface treatments like shot peening. Not sure if your design is safe? Tools like Spring Creator 5.0 let you preview stress levels, deflection, and estimated lifespan before you buy or build. With smart design and care, torsion springs can quietly and reliably power your projects for years.

Key Takeaways for Smarter Design and Selection

Torsion springs may be simple in concept, but understanding their nuances can help you make the best choice for your project – or design one with confidence. We’ve covered how they function, what affects their longevity, how to measure them, and where to find or design them. Keep these key takeaways in mind as a quick reference:

-

Torsion Spring Basics: Torsion springs store energy by twisting their coils. They exert a restoring torque to return to their original position, making them ideal for hinges, clamps, and any application requiring a rotational spring force. Always match the spring’s wind direction to the load direction to ensure it works properly.

-

Longevity Factors: A torsion spring’s cycle life depends on design stress, material, and usage. Avoid overstressing a spring and choose corrosion-resistant material or coatings for harsh environments. Proper installation (aligned on a shaft, minimal friction) and occasional lubrication will maximize the spring’s lifespan.

-

Measuring Springs: When replacing or specifying a spring, measure carefully – wire diameter, coil diameter, number of coils, leg lengths, leg angle, and wind direction. Use calipers or micrometers for accuracy (to the nearest 0.001 inch or 0.01 mm). Precise measurements ensure you can find a matching stock spring or correctly communicate specs for manufacturing.

-

Stock Spring Sources: Save time by checking stock torsion spring catalogs from spring suppliers. For example, Acxess Spring’s The Spring Store offers around 1,000 stock torsion springs in its online catalog. You can search by dimensions and get a spring off-the-shelf, which is often quicker and more economical than custom-making one.

By understanding these points, engineers and buyers can make informed decisions about torsion springs – ensuring safety, performance, and durability in whatever project they’re working on. Torsion springs are like the quiet force behind many mechanisms; with this knowledge, you can leverage that force effectively in your own designs or applications.

Enhance your projects with Spring Creator 5.0

Precision is crucial in spring design, and with Spring Creator 5.0, you can achieve it with ease. Our tool allows you to design different types of springs and offers advanced features such as instant quotes and real-time simulations with the Online Spring Force Tester. Register now and access all the benefits of our platform. Create the perfect spring and take your projects to the next level!

Created by Alfonso Jaramillo Jr

President Acxess Spring

Over 40 Years of Experience in Spring Engineering and Manufacturing