Custom Spring Information

- Manufacturing

-

- Spring Suppliers

- Precision Coil Springs California

- Pull Springs Manufacturers

- Compression Springs Wholesale

- Extension Springs Wholesale

- Tapered Springs Wholesale

- Torsion Springs Wholesale

- Coil Springs Manufacturers

- Spring Makers and Distributors

- Extension Springs Assortment

- Torsion Springs Cost

- Bulk Compression Springs

- Custom Springs: The Perfect Fit for Your Project?

What are Custom Springs?

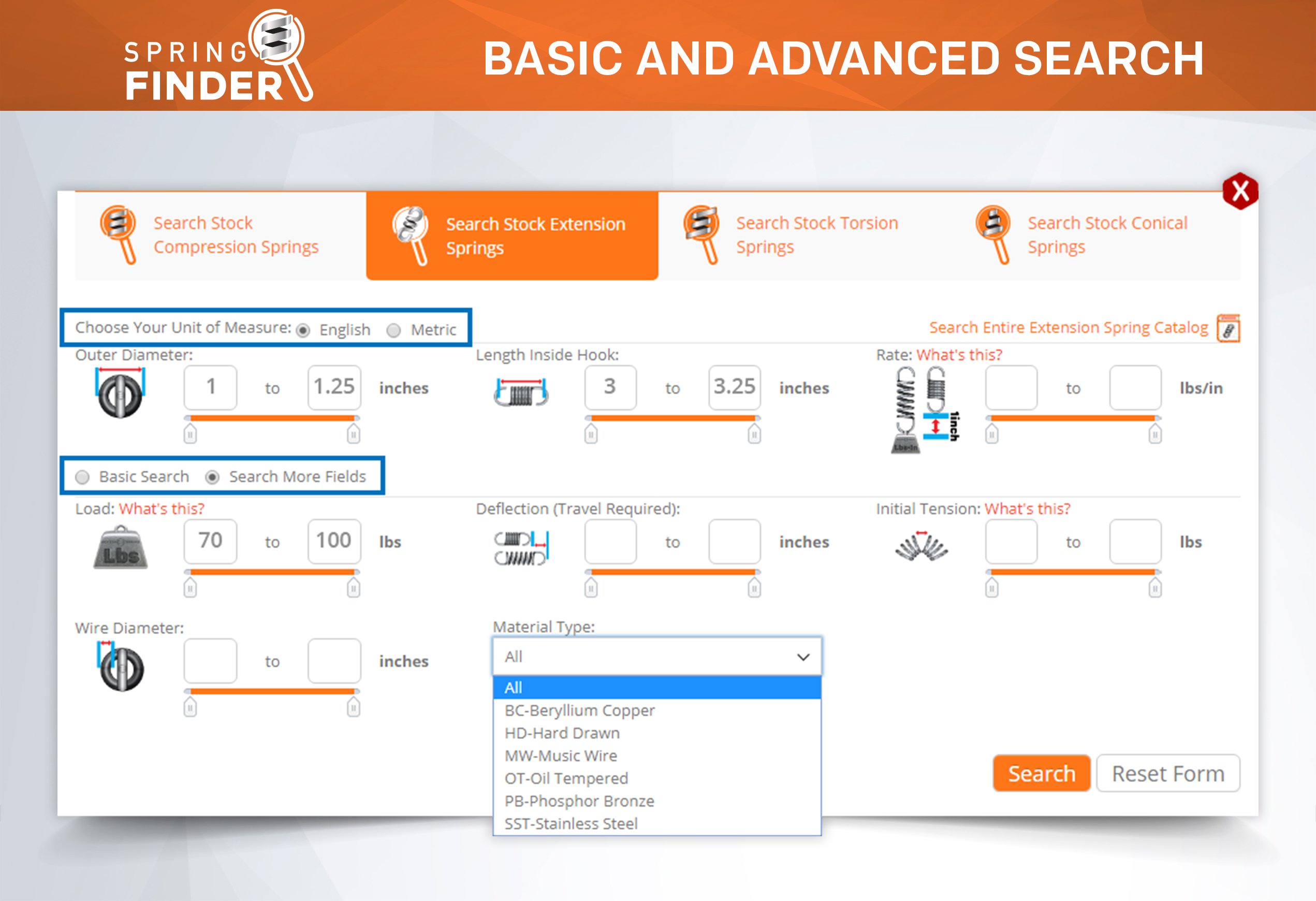

If you have ever tried to fit a stock spring into a piece of machinery only to realize it doesn’t quite meet the load it needs, or if you discovered it deforms too quickly, you already understand why custom springs are essential. Customization ranges from adjusting coil outer diameter, wire diameter, and material composition to specifying surface treatments or overall shape (e.g., conical, dual-pitch, etc.).

In today’s global market, custom spring manufacturers, like Acxess Spring , make it simpler than ever to prototype and mass-produce springs tailored to unique specifications. The possibilities are, indeed, endless. This article will walk you through the different custom spring options, the applications that often benefit from them, and the materials and manufacturing processes that could help you get from design to fully functional components and where you can get more information on our site.

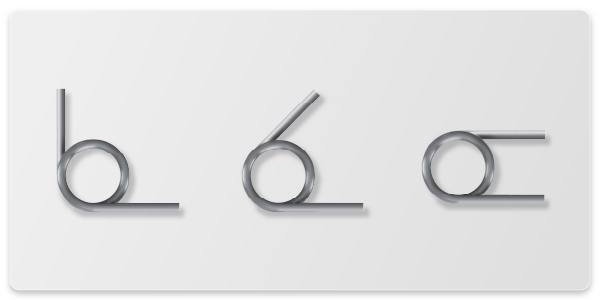

Custom Spring Types

The phrase “custom spring” can encompass any of the fundamental spring categories. Most commonly, designers seek out custom compression springs because these are among the most used springs in mechanical devices. However, custom versions of extension and torsion springs also exist, as do variants like dual-pitch compression springs, garter springs, and heavy-duty springs designed for intense applications.

Custom Dual-Pitch Compression Springs

Dual-pitch springs are a specialized type of compression spring that feature two distinct coil spacing (pitches) within a single spring. This design allows one section of the spring to compress more readily (often at a lower rate) while another section compresses more rigidly. The benefits include:

- Variable Force Output: Ideal for applications where the device needs a softer initial response, followed by a firmer compression.

- Space Optimization: Different pitch sections can help optimize the available space in your mechanism.

Custom Wire Springs

Wire springs can refer to any spring made from a specific gauge or type of wire, but the key is customization. From compression to extension or even torsion springs, the possibilities with custom wire springs include:

- Choice of Wire Diameter: You can choose a wire thickness precisely suited to your load requirements.

- Material Selection: From stainless steel to music wire, a range of materials can be used to accommodate various stress levels and environmental conditions.

- Unique Geometries: You’re not limited to cylindrical coils; wire springs can be formed into custom shapes for specialized tasks.

Double Cone Springs

Double cone springs, sometimes called “barrel springs,” taper towards both ends, giving them a distinctive barrel-like shape. This shape is particularly useful for:

- Stable Compression: Their design can help reduce buckling when the spring is compressed.

- Fitting in Tight Spaces: Because of the tapered ends, the spring can nest or reduce in diameter, often allowing for more compression in a limited area.

- Aesthetic and Functional Versatility: Such springs can be used not just for mechanical integrity but also for designs where the look of the spring matters.

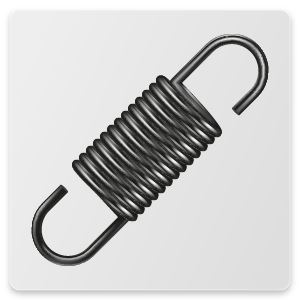

Expansion Springs

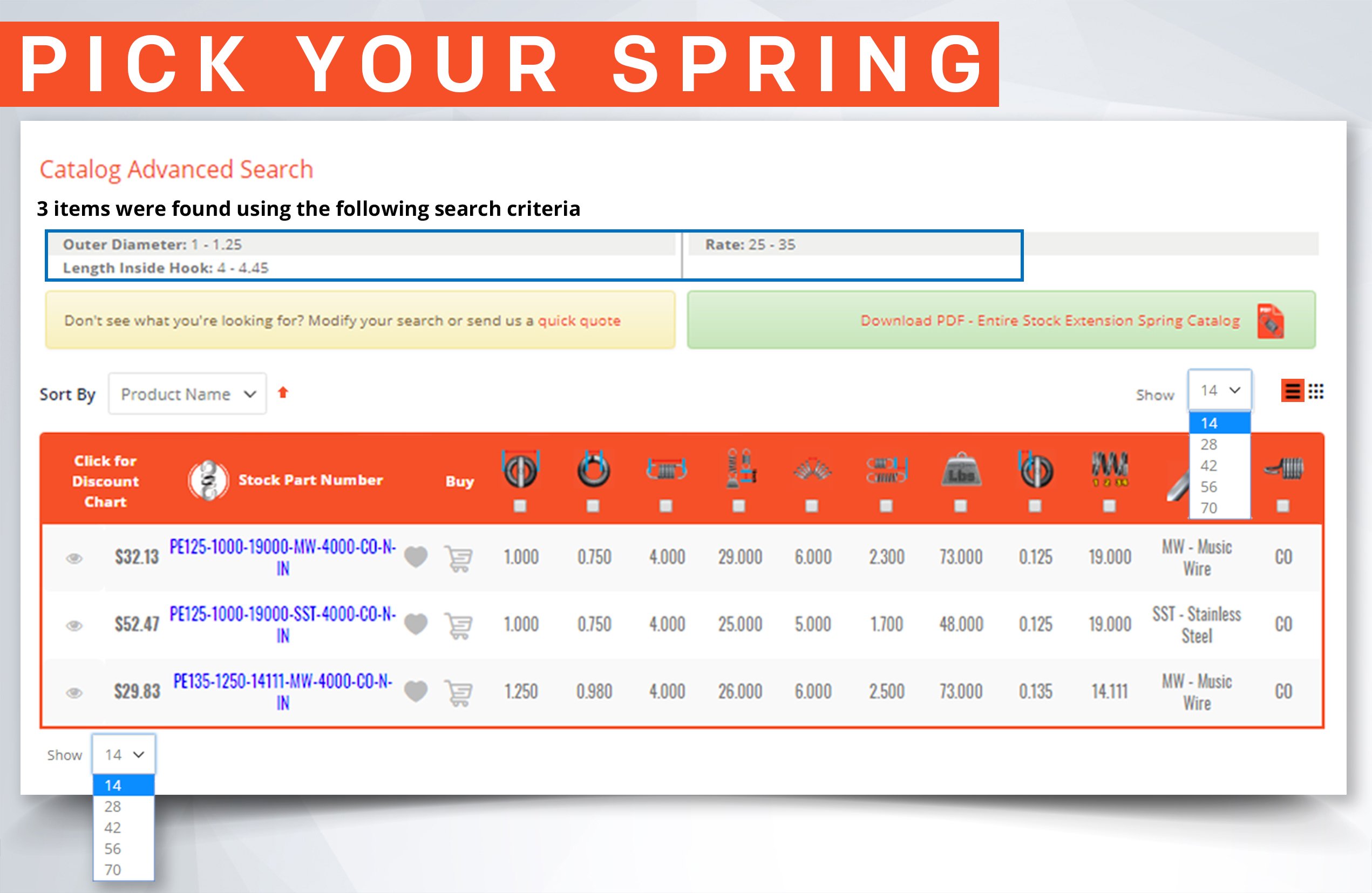

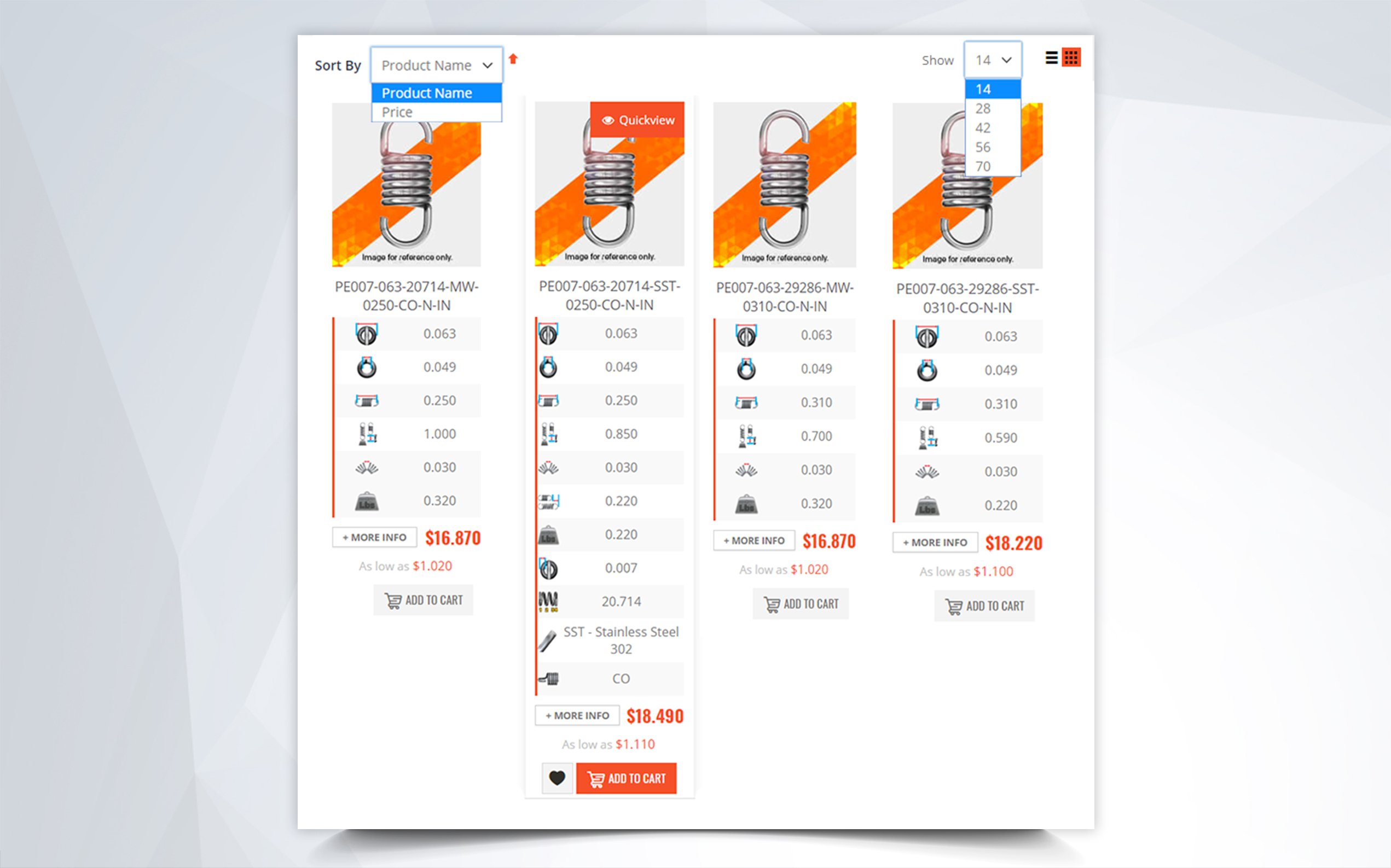

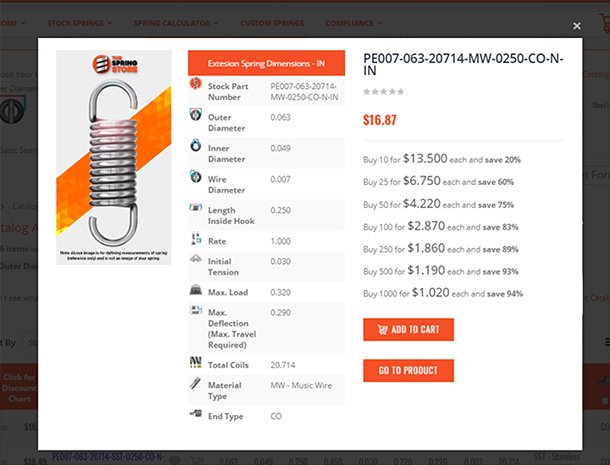

Expansion springs, more commonly referred to as extension springs , are designed to extend and absorb energy. While they are standard in many devices (like garage doors), custom extension springs become critical when:

- Exact Spring Rate is Needed: Off-the-shelf extension springs might not offer the precise tension needed for your application.

- Loop or Hook Style Adjustments : You might require special loop configurations (extended loops, V-shaped, crossover, etc.).

- Unique Load Requirements: Some applications call for particularly high or low tension, which can be achieved through careful design of coil diameter, length, and material type.

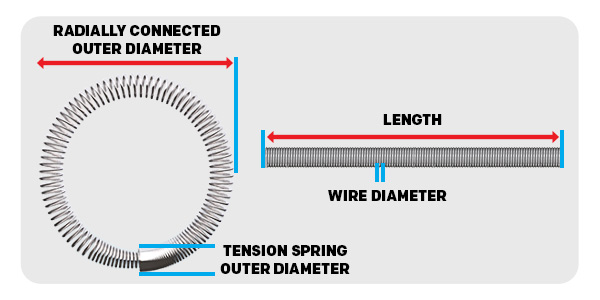

Garter Springs Manufacturers

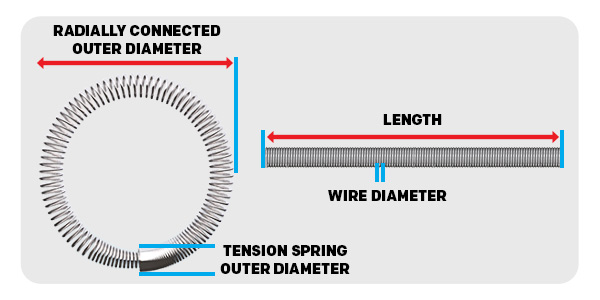

Garter springs are extension springs that connect at both ends to form a ring. Often used for sealing, such as oil seals or belt-driven systems, garter springs can be customized in:

- Diameter of the Ring: The size of the ring must match the sealing or drive application precisely.

- Tension Requirements: Garter springs may need to maintain consistent tension around a shaft or cylindrical object.

- Material Coatings: Depending on the environment (e.g., chemical exposure), specialized coatings or materials (such as stainless steel) might be required.

Heavy Duty Springs

Heavy duty springs can be large compression springs or any robust spring designed to handle high loads and large deflections . Commonly found in industrial machinery and automotive applications, heavy duty springs:

- Use Thicker Wire Gauges: Thicker wire can handle greater loads.

- Require Rigorous Testing: They must endure repeated cycles under extreme stress, making high-quality materials and precision manufacturing critical.

- Offer Greater Energy Storage: Whether for shock absorption, supporting heavy loads, or powering large mechanisms, heavy duty springs are integral to many large-scale applications.

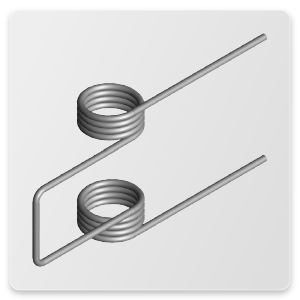

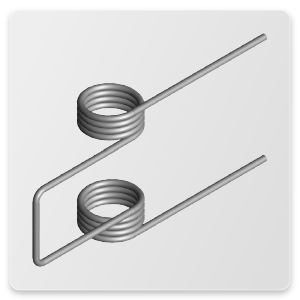

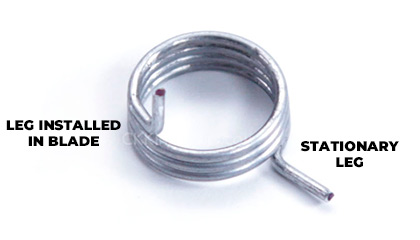

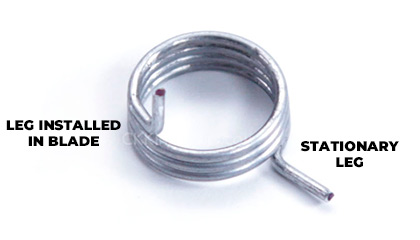

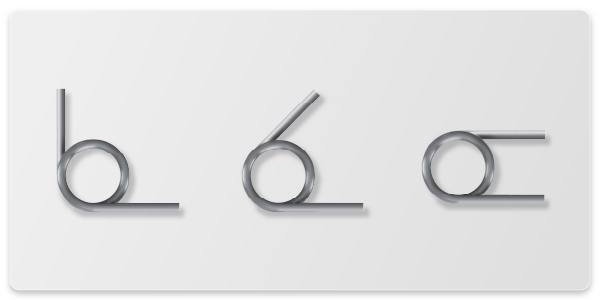

Rotational Springs

Rotational springs (also known as torsion springs) store energy by twisting rather than compressing or extending. In a custom context, rotational springs:

- Can be Designed for Specific Torque Ranges: The coil diameter, wire diameter, and coil count all influence torque capacity.

- Have Varied Leg Configurations: The “legs” (ends of the spring) can be bent or formed into shapes that suit a particular latch, lever, or rotational axis.

Specialty Springs

“Specialty springs” is a broad category that might include springs with non-standard shapes or made from exotic materials. These springs:

- Handle Harsh Environments: Some projects involve corrosive chemicals, saltwater, or extreme temperatures. Specialty materials stand up to these conditions.

- Often Require Tailored Manufacturing Processes: Producing specialty springs can involve advanced forming techniques, heat treatments, or surface finishing.

Custom Spring Applications

Understanding where custom springs are commonly deployed can help you identify the exact specs you need. Sometimes, design inspiration comes from seeing how similar devices use springs.

Spring Loaded Applications

A spring-loaded mechanism essentially uses the spring’s stored energy to trigger an action. From small push buttons in consumer electronics to release mechanisms in large industrial latches, spring-loaded applications rely on:

- Quick Actuation: The spring’s compression or extension force is used to rapidly move parts.

- Reset Capabilities: After actuation, many devices need the spring to return to its initial state, providing a self-resetting feature.

- Fine-Tuned Tolerances: In some mechanical systems (such as measurement instruments), the spring must provide highly accurate and consistent force.

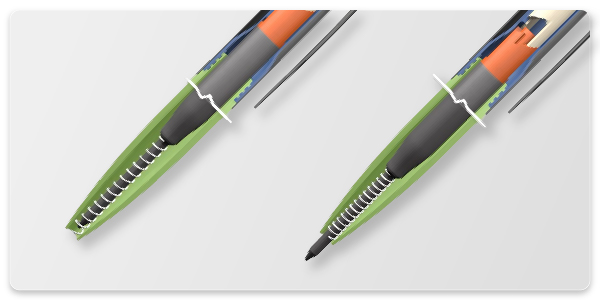

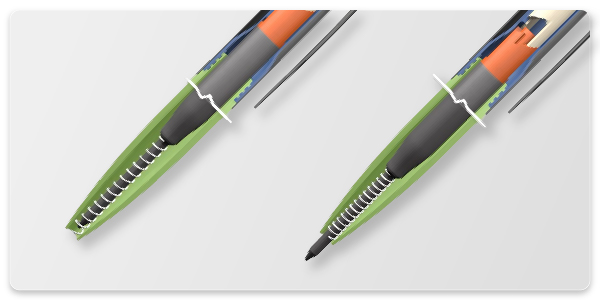

Springs for Ballpoint Pens

A classic example of an everyday product that uses compression springs is the ballpoint pen. The custom requirements for pen springs often include:

- Small Form Factor: Springs must fit within a narrow internal chamber.

- Soft Touch and Controlled Tension: The writing mechanism should extend and retract smoothly with minimal force needed from the user.

- High Cycle Life: Pen springs are compressed every time the pen is clicked, requiring the spring to maintain its properties over thousands of cycles.

Springs for Knives

Folding knives, particularly those with assisted-opening or automatic mechanisms, use torsion or compression springs to aid or control the blade’s movement. The factors to consider include:

- Precise Torsion Strength: The spring must keep the blade securely in place, both folded and extended.

- Wear Resistance: Knives may be exposed to dirt, moisture, or frequent usage, so springs must resist corrosion and deformation.

- Compact and Discrete: The knife handle usually has limited space, requiring a carefully sized spring.

Springs for Medical Devices

Medical devices often require precision, reliability, and sterility. Examples range from syringe plungers to more complex implantable devices or surgical instruments. Key considerations for custom medical springs are:

- Sterile or Biocompatible Materials: For devices used in direct contact with the human body (e.g., implants), medical-grade stainless steel or other biocompatible materials may be required.

- Exact Dimensions: The tight tolerances in medical engineering demand that springs match precise length, diameter, and force specifications.

- Smooth Surface Finishes: Minimizing surface imperfections can help avoid contamination and improve cleanliness.

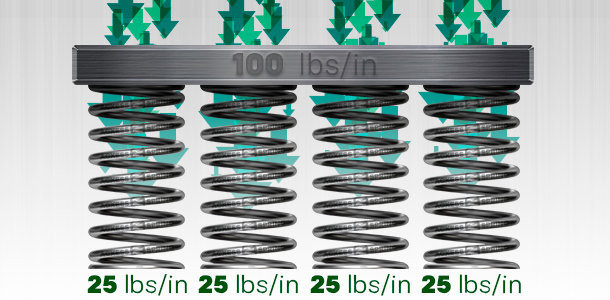

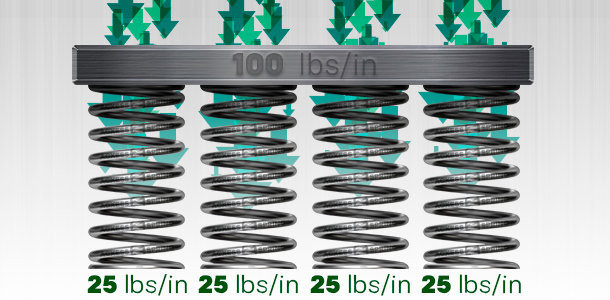

Springs in Parallel

When two or more springs are arranged in parallel, the effective spring rate (k) is the sum of the individual spring rates. This arrangement is used for:

- Increased Load Capacity: Parallel springs can handle greater loads than a single spring.

- Adjustable System Stiffness: By swapping out or adding springs, engineers can fine-tune the system’s overall stiffness.

- Redundancy: If one spring fails, the others can still support the load to some extent.

Large Compression Springs

Large compression springs specifically are found in applications where significant force is needed to hold or return components. They must:

- Resist Buckling: As compression grows, long or large-diameter springs can buckle if not properly supported.

- Handle High Loads: They need materials and heat-treating processes that maintain elasticity under intense force.

- Maintain Consistent Performance Over Numerous Cycles: Large springs in industrial contexts, like press machines, can cycle thousands of times daily.

Large Extension Springs

Large extension springs are typically used in garage doors, industrial doors, or heavy lifting mechanisms. They must be designed with:

- Safe and Secure End Loops: Given the high tensions, failure at the loop could be catastrophic.

- Corrosion Resistance: Garage or industrial environments might introduce moisture, chemicals, or temperature fluctuations.

- Proper Preload Tension: Ensuring the correct initial tension is crucial for how the spring will perform in supporting or lifting large objects.

Large Torsion Springs

Large torsion springs appear in applications such as heavy-duty hinges , automotive suspension systems, and even agricultural machinery. Customizing these springs involves:

- Precise Torque Requirements: The spring’s geometry must deliver the correct twisting force without deforming beyond its elastic limit.

- Leg or Arm Angles: The angle and length of the torsion spring’s legs are often critical in how the application engages the spring’s torque.

- Rugged Materials: Large torsion springs generally need materials capable of bearing repeated torsional stress.

Material Types

Choosing the Right Spring Material

Choosing the right material is a core aspect of designing a custom spring. Different metals and alloys offer unique trade-offs in terms of elasticity, corrosion resistance, temperature tolerance, and cost. The material selections provided here serve as a starting point.

Stainless Steel - Coil Spring Design

Stainless steel is one of the most popular options for custom springs because it offers:

- Corrosion Resistance: Particularly important for outdoor or moisture-rich environments.

- Good Elastic Properties: Stainless steel maintains good elasticity and strength over time.

- Versatility in Grades: Multiple grades exist, each offering different mechanical properties. For many standard springs, 302 or 316 stainless steel may be used.

Stock Music Wire Compression Spring

Music wire is a high-carbon steel known for its excellent tensile strength and uniformity. Common uses:

- Instrument Springs: Music wire was historically used for piano strings, known for consistent performance.

- High-Stress Environments: It holds up well under repeated stress and has a high tensile strength.

- Smaller Springs: Music wire is often drawn into thinner gauges, making it suitable for small or medium springs.

Stock Music Wire Extension Springs

Extension springs made from music wire share many of the same properties as compression types but are designed to extend. They typically:

- Offer Excellent Fatigue Life: Well-suited for repeated tension and release cycles.

- Provide High Tensile Strength: Ensuring the spring resists breaking or permanent deformation.

- Remain Economical: Music wire is relatively affordable compared to some stainless steel alloys.

Stock Music Wire Torsion Springs

Music wire torsion springs are frequently seen in applications where torque is moderate, and cost-effectiveness is a factor. They are popular because:

- Easy to Form: Music wire can be coiled into torsion spring shapes without excessive difficulty.

- Dependable Material Properties: Consistent elasticity and stress handling.

- Ideal for Prototyping: If you’re unsure of the final design, starting with a music wire torsion spring is often cost-effective and informative.

Manufacturing

Manufacturing custom springs involves more than simply coiling metal wire. Factors like the production quantity, tooling, heat treatment, and finishing can greatly affect both the cost and the quality. For instance, buying springs in bulk (wholesale) is typically cheaper on a per-unit basis than purchasing small retail quantities. Moreover, finishing processes such as shot peening or electroplating may be necessary to enhance fatigue life or corrosion resistance.

Spring Suppliers

Spring suppliers range from small local workshops that specialize in prototypes and low-volume runs to large factories capable of mass production. When seeking a supplier:

- Evaluate Capabilities: Ensure they can produce the wire diameter, shape, and material you need.

- Check Lead Times: Custom springs can have longer lead times, especially for complex designs.

- Compare Costs and Quality: Balance affordability with robust manufacturing and testing practices.

Precision Coil Springs California

In regions like California, a variety of precision coil spring manufacturers cater to industries like aerospace, medical, and automotive. Working with specialized suppliers can offer:

- Advanced Technology: Access to CNC coiling machines for high precision.

- Regulatory Compliance: Familiarity with certifications such as ISO.

- Local Proximity: If you’re in the area, local suppliers provide easier site visits and faster shipping.

Pull Springs Manufacturers

Pull springs, another term for extension springs, are critical in applications requiring tension. Manufacturers focusing on pull springs:

- Offer Standard & Custom Hooks/Loops: Essential for attaching the spring in your assembly.

- Can Provide Varied Pre-load Forces: Ensuring a “pull” that activates or holds mechanisms in place.

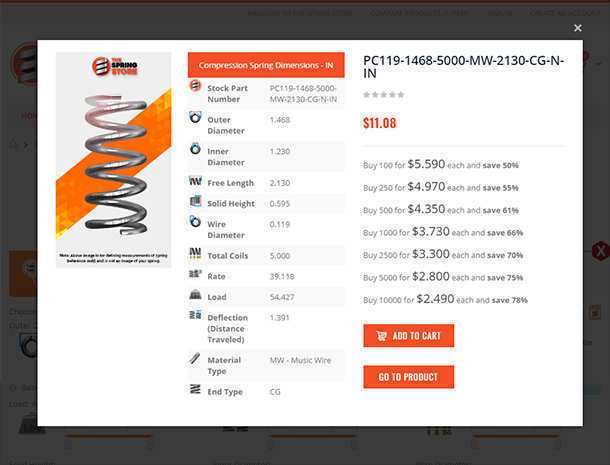

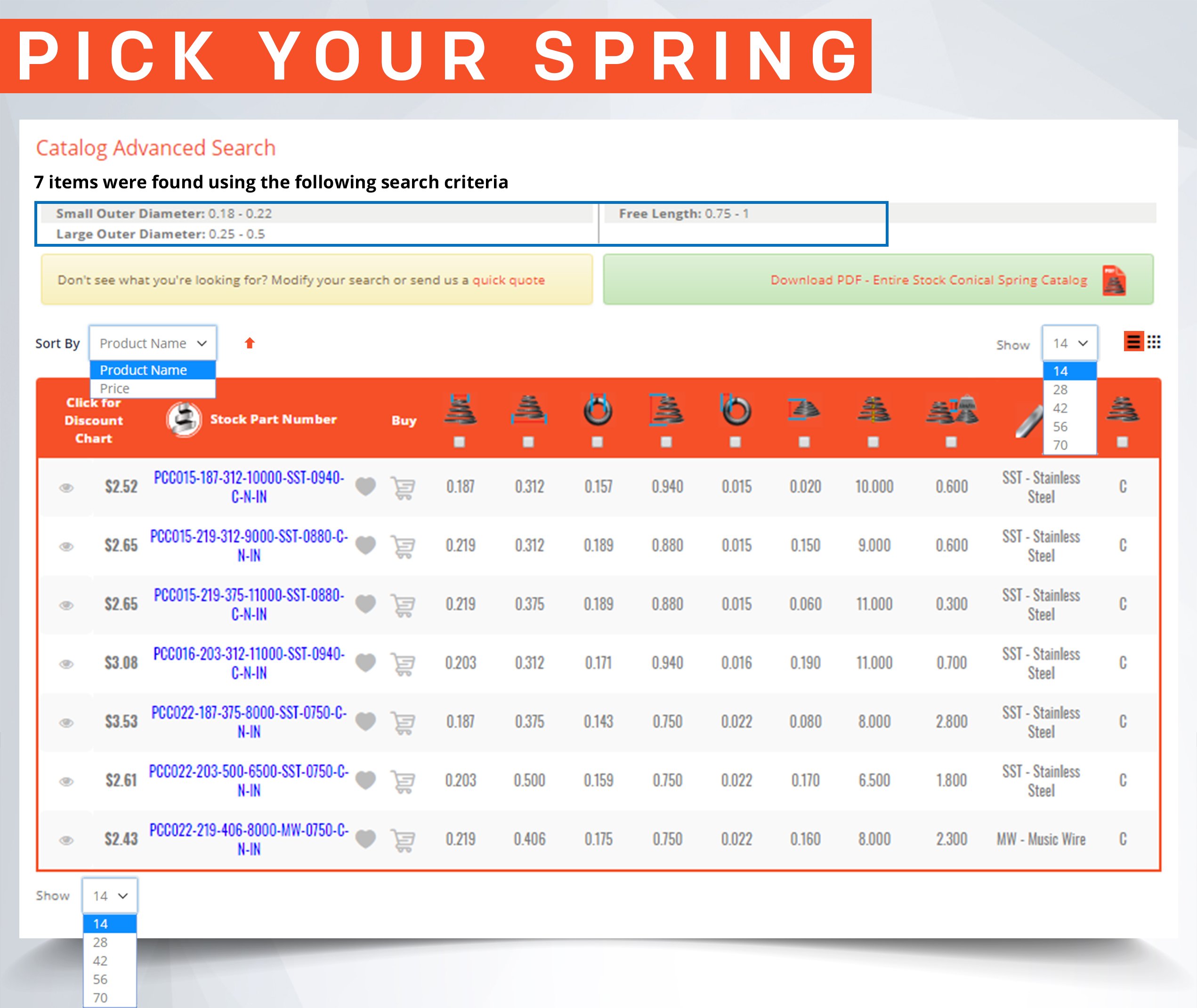

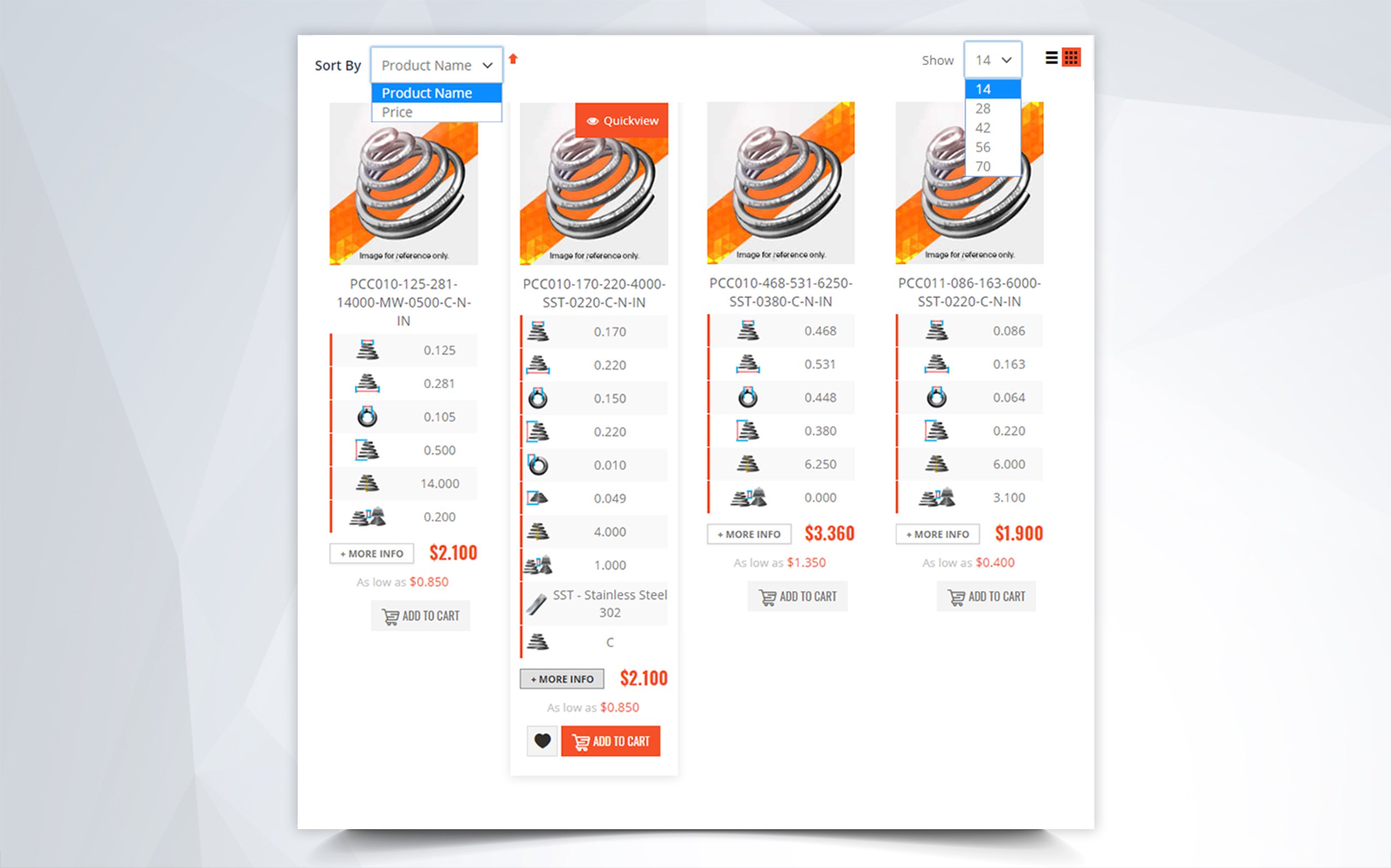

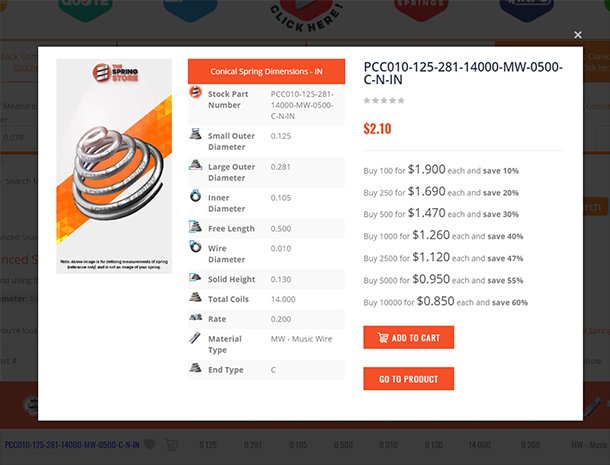

Compression Springs Wholesale

Many industries need large quantities of compression springs—often in the thousands or even millions. Wholesale compression spring suppliers:

- Provide Bulk Discounts: The more you order, the cheaper the per-unit cost.

- Maintain Consistency Across Batches: Key for large-scale manufacturing where every spring must meet the same specifications.

- Possess Automated Equipment: Minimizing manual errors and speeding up production.

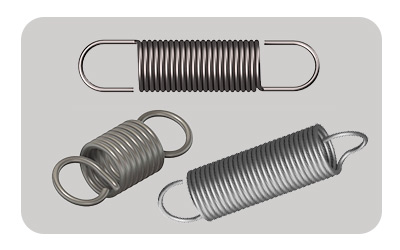

Extension Springs Wholesale

As with compression springs, extension springs are also purchased in bulk by sectors like automotive and heavy machinery. Wholesale extension spring suppliers:

- Handle High-Volume Runs: Effective for industries that require standardized designs for repeated use.

- Offer Customizations for Large Orders: Many suppliers are flexible when orders reach certain minimums.

- Manage Inventory Logistics: They can store and deliver springs in cycles if you don’t have space to keep everything at once.

Tapered Springs Wholesale

Tapered springs , including conical or barrel-shaped varieties , can be more complex to produce. Nonetheless, specialized wholesale providers:

- Rely on Precision Equipment: The coil must be tapered accurately for consistent performance.

- Offer Material Choices: Depending on load, environment, and design constraints.

- Work Closely with Designers: Ensuring the tapered geometry meets the exact compression characteristics needed.

Torsion Springs Wholesale

Wholesale torsion springs are common in everything from industrial levers to consumer product hinges. When engaging a torsion spring wholesaler, be mindful of:

- Leg Configuration Variance: Ensure you specify the angular orientation of the legs, coil direction, and torque requirements.

- Stress Limits: Torsion springs can fail prematurely if not designed and tested for the correct torque range.

- Finishing Treatments: In certain industries, a protective coating may be essential to prevent corrosion.

Coil Springs Manufacturers

Coil springs can refer broadly to compression, extension, or torsion springs since they all involve coiled wire. Manufacturers under this label often:

- Focus on Specific Niches: Some might be automotive-focused, while others might serve medical or aerospace industries.

- Provide Design Services: In-house engineers can help refine your custom design for manufacturability and performance.

Spring Makers and Distributors

Beyond manufacturing, “spring makers and distributors” may also resell springs from different suppliers, offering:

- Wide Variety: Access to multiple stock lines and the ability to handle custom orders from partnered factories.

- Streamlined Sourcing: If you need several types of springs (compression, extension, torsion) in varying volumes, a distributor can manage this seamlessly.

- Flexible Service Levels: Some distributors provide engineering support, inventory management, and logistics solutions.

Extension Springs Assortment

An extension springs assortment is particularly useful for service technicians or hobbyists who frequently work on repairs or prototypes. Having a range of sizes and tensions on hand:

- Saves Time: You can quickly pick the right spring without special ordering.

- Encourages Experimentation: If you’re prototyping or uncertain of the final specs, an assortment helps you test various options.

- Is Cost-Effective for Small Projects: Buying in sets can reduce the cost compared to individually purchasing each spring.

Torsion Springs Cost

The cost of torsion springs can fluctuate based on:

- Material Choice: Exotic metals cost more than stainless steel or music wire.

- Precision Requirements: Tighter tolerances and complex leg forms may raise costs.

- Production Quantity: Per-unit cost typically declines with higher volumes.

Bulk Compression Springs

If you need straightforward compression springs—especially in moderate to large quantities—bulk compression springs are often your best option. The key benefits include:

- Economies of Scale: The higher the order, the lower the individual spring price.

- Consistency: Bulk orders are usually produced in a single manufacturing run, maintaining uniform quality.

- Discounted Shipping: You can often negotiate shipping deals or use the manufacturer’s in-house logistics.

Custom Springs: The Perfect Fit for Your Project?

Understanding the key considerations ensures you get the perfect fit for your project. Here are 5 key takeaways:

- Customization is Key: Tailor springs to your exact needs by adjusting dimensions, materials, and shapes.

- Variety of Types: Explore the different types of custom springs available, including compression, extension, torsion, and specialty springs, to find the best match for your application.

- Material Matters: Select the right material, such as stainless steel or music wire, to meet your requirements for corrosion resistance, strength, and elasticity.

- Application-Specific Design: Consider the specific application, such as medical devices or heavy machinery, to determine the necessary precision, reliability, and load capacity.

- Manufacturing Considerations: Evaluate suppliers based on their capabilities, lead times, and cost-effectiveness to ensure high-quality production.

Ready to design the perfect custom spring for your project? Contact our spring specialist today and bring your vision to life.