Stock Small Torsion Springs

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Table of Contents

- Why Should You Consider Stock Small Torsion Springs for Your Next Project?

- What Are Stock Small Torsion Springs?

- Dimensions and Material Characteristics

- Design Considerations

- Common Applications for Small Torsion Springs

- Why Buy Small Torsion Springs in Stock?

- Selecting a Small Torsion Spring Step-by-Step

- Additional Considerations for Optimal Performance

- Making Informed Purchasing Decisions

- Partnering with a Reputable Supplier

- How to Choose the Perfect Stock Small Torsion Springs for Reliable, Long-Lasting Performance?

Why Should You Consider Stock Small Torsion Springs for Your Next Project?

Let’s face it—springs might not be the flashiest components in your devices, but when it comes to getting things moving smoothly, they’re often the unsung heroes. If you’ve ever opened a battery compartment, released a latch, or enjoyed the crisp action of a small hinge, chances are you’ve experienced the work of a tiny torsion spring. These small but mighty springs show up in countless everyday gadgets, helping them operate reliably, quietly, and efficiently. And the best part? You can easily find stock small torsion springs for sale without having to jump through the hoops of custom orders.

In this guide, we’re going to break down everything you need to know about selecting, testing, and using these miniature torsion springs. We’ll talk about what makes them special, how to measure and calculate their capabilities, and how to choose the right one for your project—whether you’re designing a new device, fixing a broken latch, or just experimenting with prototypes. Along the way, we’ll introduce you to some handy online tools like Spring Creator and the Online Spring Force Tester to make the process quicker and smoother. By the end, you’ll feel much more confident about grabbing the right small torsion spring for your needs.

What Are Stock Small Torsion Springs?

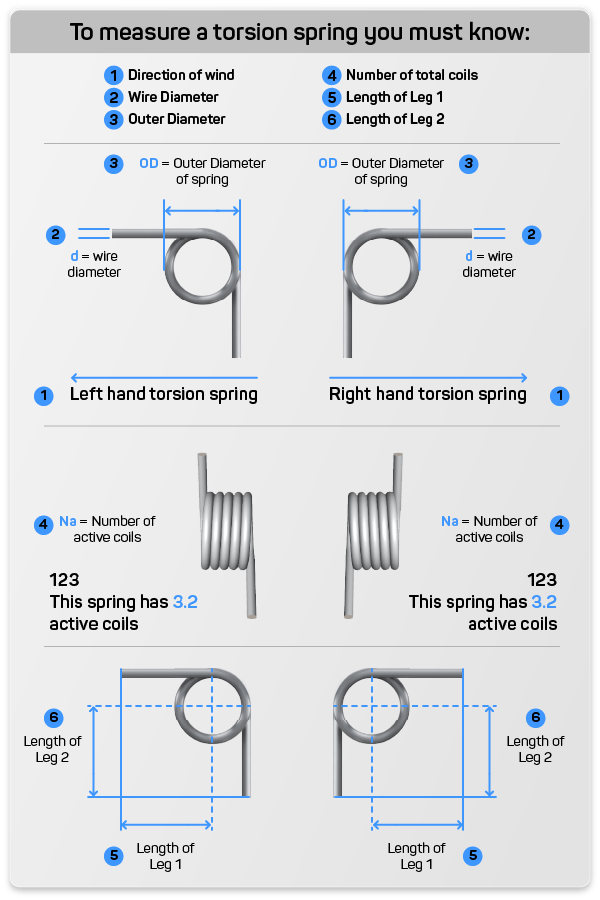

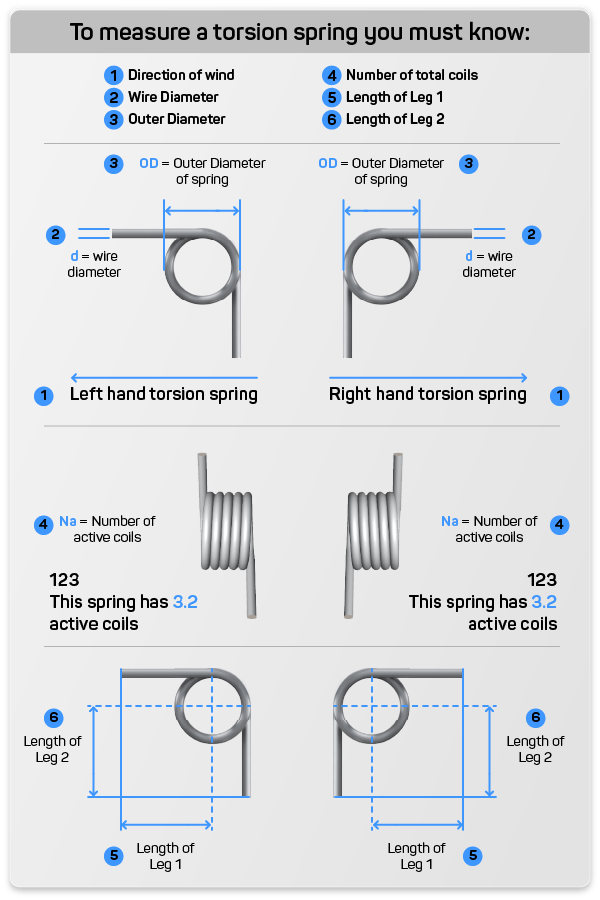

Stock Torsional springs are helical springs that provide torque or rotational force when their ends (legs) rotate around the spring’s center. “Stock small torsion springs” refers to torsion springs that are miniature and readily available for purchase from a spring supplier’s inventory. Instead of placing a custom order—complete with lead times and higher costs—you can browse an online store or online catalog, pick out the dimensions and specs you need, and have your springs shipped promptly.

Why Small Torsion Springs?

Small torsion springs are key for devices where space is limited and precision is important. Think of tiny hinges, camera shutters, battery compartment doors, and various miniaturized assemblies. These springs are the behind-the-scenes players ensuring everything moves just right. By choosing a ship's today stock small torsion spring, you tap into a world of convenience, cost savings, and speedy shipping times.

Dimensions and Material Characteristics

Ships today stock small torsion springs generally fall within very narrow dimensional categories. Wire diameters often range from about 0.016" (0.406 mm) to 0.035" (0.889 mm), and inner diameters (ID) usually measure between 0.151" (3.84 mm) and 0.350" (8.89 mm). This compact size makes them ideal for miniature applications where space is at a premium. For example, if you’re fitting a spring into a delicate hinge mechanism in a camera or a small latch inside a medical device, these tiny dimensions matter enormously. The right fit ensures smooth action without binding or unnecessary friction, helping maintain the quality and longevity of the device.

Material Options:

While size considerations are crucial, material selection should not be overlooked. The choice of material has a direct impact on corrosion resistance, fatigue life, and performance stability, especially under varying environmental conditions.

- Music Wire ASTM A228: A common choice for small torsion springs, music wire is a high-carbon steel known for its excellent tensile strength and consistent performance. It’s suitable for many indoor applications where moisture and corrosion are not significant concerns.

- Hard Drawn Wire ASTM A227: If cost is a big factor and your application doesn’t demand extreme durability or corrosion resistance, hard drawn wire can be a more economical alternative. Though it’s not as strong as music wire, it still provides reasonable performance for general-use scenarios.

- Stainless Steel (302 astm a313, 316, etc.): For applications involving moisture, chemical exposure, or variable temperatures, stainless steel shines. It offers a higher degree of corrosion resistance, making it an excellent choice for outdoor devices, marine equipment, medical instruments, or products exposed to sweat and oils. Stainless steel’s durability also ensures that your small torsion spring retains its mechanical properties over a longer period, reducing the need for frequent replacements.

Finishes and Platings:

If you need to further boost corrosion resistance, enhance appearance, or maintain consistent performance in demanding environments, consider special coatings or finishes. Zinc plating can provide a protective barrier against rust, extending the spring’s service life. Gold irridite (chemical conversion coating) is another option—while often used for aesthetic reasons, it can also impart certain protective qualities. Such finishes may be key in environments where even minor corrosion could compromise the spring’s performance or lead to early failure.

Design Considerations

Designing with small torsion springs involves balancing multiple factors to achieve optimum performance and longevity. Before committing to a particular spring, keep these considerations in mind:

- Torque and Angular Deflection: Start by knowing how much torque you need at a given angle of rotation. Will the spring need to move just a few degrees or a full 180° turn? Understanding the required angle ensures you select a spring that won’t be overstressed, preserving its useful life.

- Space Constraints: Small springs often fit into tight spaces. You’ll need to measure carefully to ensure the spring’s coil diameter, leg length, and total shape can be accommodated. Consider not only static dimensions, but also how the spring’s legs move during operation.

- Material Selection: The operating environment guides material choice. Music wire works well indoors at room temperature, while stainless steel is better for corrosive or damp conditions. For extra durability, consider special finishes that enhance corrosion resistance.

- Fatigue Life and Cycles: If the spring is cycled frequently, fatigue life becomes critical. Check recommended torque and travel deflection limits to avoid permanent set or breakage over time. Designing within safe stress limits ensures reliability and reduces maintenance costs.

- Mounting and Alignment: How will the spring attach to the device? Ensure there’s proper support for the coil body and alignment of the legs. Misalignment can cause uneven stress distribution and lead to premature failure. Thinking through these details at the start helps you select a torsion spring that not only fits your specs but also stands the test of time.

Common Applications for Small Torsion Springs

Though small torsion springs might look humble, their presence is widespread, delivering vital functions in countless products and industries. Understanding where they are commonly used can help you appreciate their importance and possibly spark ideas for your own projects:

- Consumer Products: Think about battery compartment doors on remote controls, hinges on eyeglasses, and tiny lids on handheld gaming devices. Small torsion springs provide the crisp, controlled motion that makes these everyday items more user-friendly and reliable.

- Electronics and Gadgets: Within your smartphone’s SIM card tray or a camera’s delicate lens shutters, tiny torsion springs offer just the right amount of torque to ensure smooth, repeatable motions. They’re often integral in push-button assemblies, switches, and protective caps for ports or connectors.

- Automotive and Aerospace: On a smaller scale, torsion springs help in miniaturized latches, sensor housings, and adjustable vents found throughout car interiors. In aerospace applications—where size, weight, and reliability are paramount—small torsion springs help ensure that access panels, control surfaces, and protective covers operate flawlessly.

- Medical Devices and Instruments: Precision is essential in medical tools. Small torsion springs can be found in surgical clamps, pill dispensers, infusion pumps, and diagnostic equipment. Their consistent performance and repeatability contribute to patient safety and dependable results.

- Industrial Machinery and Robotics: In compact automated systems, sensors and small mechanical arms rely on miniature torsion springs for smooth pivoting action. These springs ensure that safety covers, indicator flags, or assembly line gates return to their initial positions reliably.

Ultimately, any application that involves controlled rotational movement in a small space is a candidate for a small torsion spring. Their versatility and robustness make them a go-to solution across numerous fields.

Why Buy Small Torsion Springs in Stock?

Buying ships today in stock small torsion springs from the spring store offers a range of advantages, especially when you’re balancing time, cost, and quality. Here’s a closer look at why starting with stock solutions often makes the most sense:

- Immediate Availability: One of the biggest perks is that you don’t have to wait around for a custom manufacturing process. Ships today stock torsion springs are ready to ship on the same day, meaning you can receive them quickly and keep your project’s momentum going. The spring store has over 40,000 different in stock spring designs. This is particularly valuable if you’re dealing with unexpected equipment failures or tight deadlines.

- Lower Upfront Costs: Customized torsion springs require tooling, setup fees, and minimum order quantities that can drive up costs—particularly if you’re only experimenting or need a small batch. Ships today in stock torsion springs, on the other hand, are produced in volume and ready on the shelf, which often translates to more affordable pricing at lower quantities.

- Prototyping Made Easy: When you’re in the prototyping phase of product development, you might not have nailed down every detail of your design yet. Ships today stock small torsion springs let you test different dimensions, spring rates, and materials without committing to a particular configuration. This flexibility helps you refine your design until you’re sure of the specs you need.

- Wide Selection: We have over 70 Trillion spring configurations to choose from in various dimensions, materials, and torque capacities. Having so many options at your fingertips means you can often find a spring for your ideal specs right away. If not a perfect match, it can guide you on what adjustments to make for a later custom order.

- Verification of Calculations: Using a ships today in stock spring as a baseline is a great way to confirm your load and torque calculations. You can quickly test it in the actual device and ensure that the theoretical numbers match real-world performance. If everything lines up, you’re good to go. If not, you can course-correct early in the process.

In short, buying stock small torsion springs is a strategic move that streamlines development, keeps costs in check, and lets you make informed decisions at every step of your project.

Selecting a Small Torsion Spring Step-by-Step

Turning theory into practice is often where the real learning occurs. While formulas, calculators, and design considerations are all invaluable, seeing how they come together in a real-world scenario can clarify the selection process. Below are two detailed examples that walk through the steps of picking the right small torsion spring for your needs.

A Small Hinged Door on a Portable Electronic Device

Scenario:

Imagine you’re developing a portable electronic device—a handheld gaming console, for instance—with a small hinged door that covers the battery compartment. You want this door to open smoothly and remain stable in either the closed or open position. It needs a

torsion spring

that provides just enough torque to hold it firmly closed without requiring excessive force to open.

Step-by-Step Approach:

-

Identify the Requirements:

Start by considering the size of the hatch: let’s say it has a body length of about 0.21 inches. The door rotates approximately 90° from closed to fully open. -

Estimate Torque and Deflection:

You want a gentle, reassuring “snap” as it closes, which might call for around 0.05 in-lb of torque when the door is near the closed position. That means, you need around 0.05 in-lb at 90° rotation. This is your target torque and deflection angle. -

Set Dimensional Constraints:

Inside the device, space is limited. You may only have room for a spring with an inner diameter (ID) of around 0.200" to 0.250" and a wire diameter (WD) that won’t overwhelm the delicate plastic mounting posts. Perhaps a wire diameter of around 0.020" is a good starting point. Around 8 to 12 total coils. -

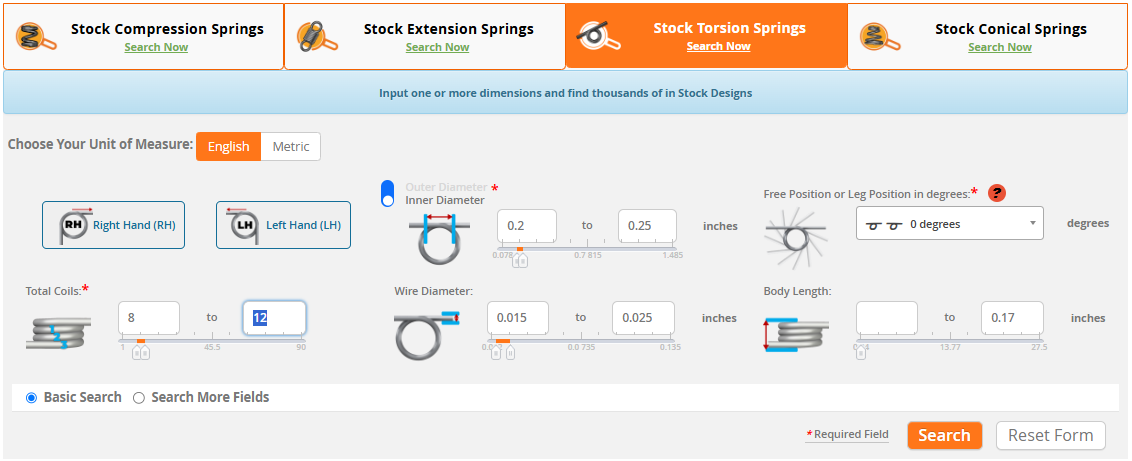

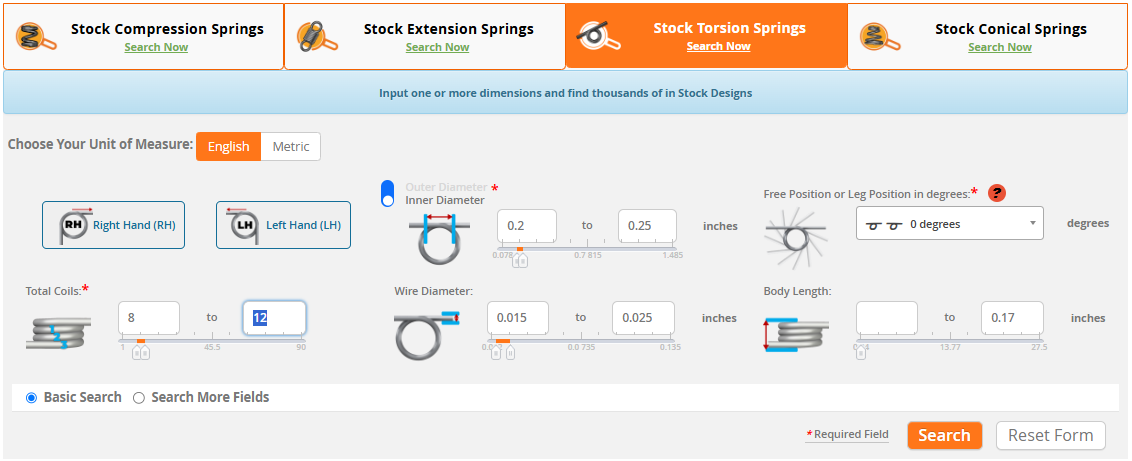

Use Spring Finder 5.0:

Head to The Spring Store, navigate to Spring Finder 5.0, select Stock Torsion Spring and input your tentative specs:- Wire diameter: ~0.020"

- Inner diameter range: ~0.200" to 0.250"

- Total Coils: ~8 to 12 coils

- Angle of deflection: 90°

- Required torque: 0.05 in-lb at that angle

Spring Finder 5.0 might list several springs that meet or approach these parameters.

-

Compare Multiple Options:

Review the list or filter for candidate springs. If one spring offers 0.04 in-lb at 90°, it may be slightly weaker than required. Another might yield 0.06 in-lb at 90°, which is a bit stronger. You might choose the 0.6 in-lb spring for a more secure snap, or the 0.4 in-lb if you prefer easier opening. -

Consider Material and Finish:

Since this device will likely be used indoors, music wire might suffice. If it might face humidity or if you want longer life, consider stainless steel. Also check if a protective plating like zinc might extend its lifespan. -

Choose a spring:

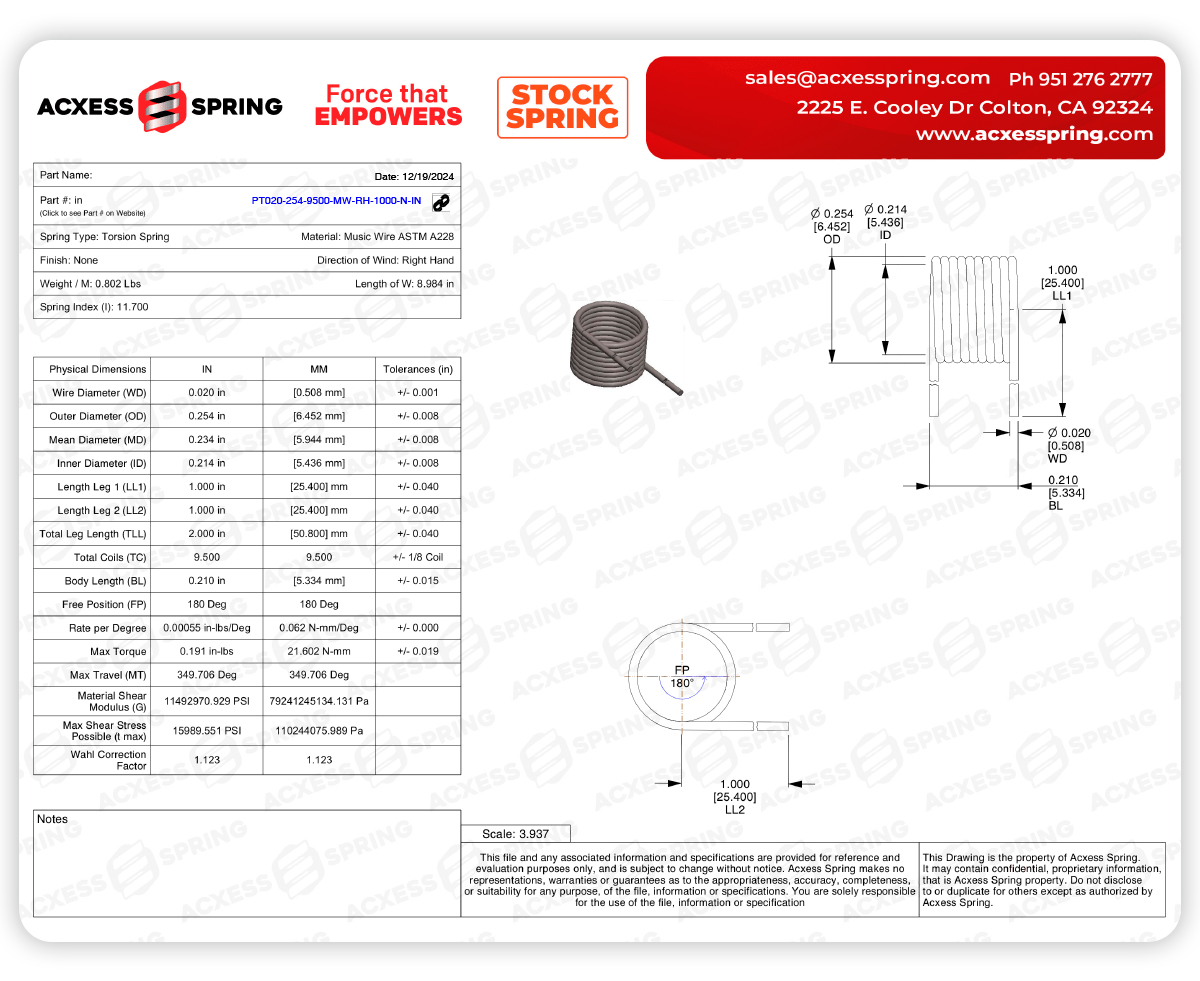

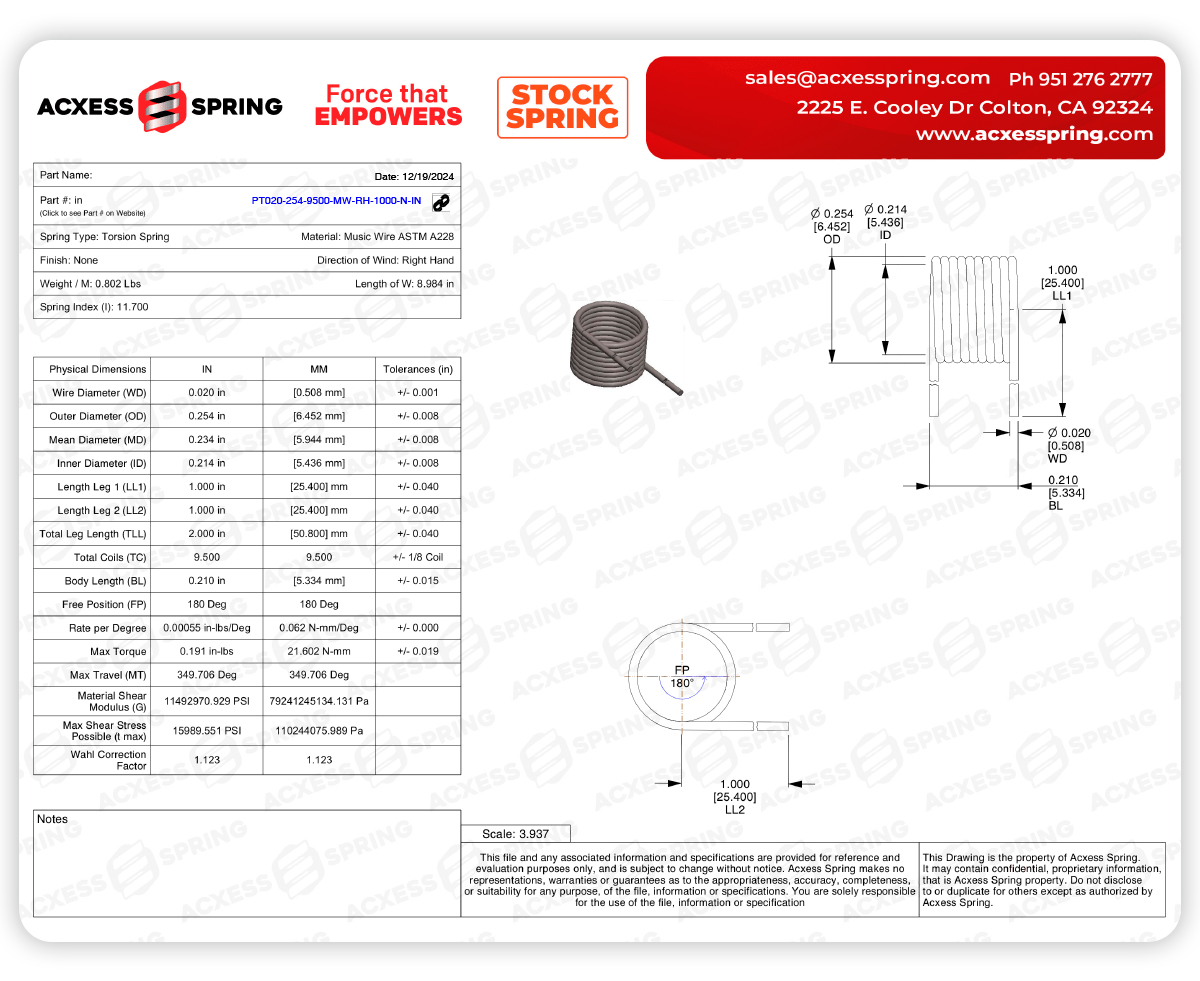

Once you narrowed down your options, select the spring that better matches your requirements. In this case, we choose Stock Part Number PT020-254-9500-MW-RH-1000-N-IN

-

Test your spring:

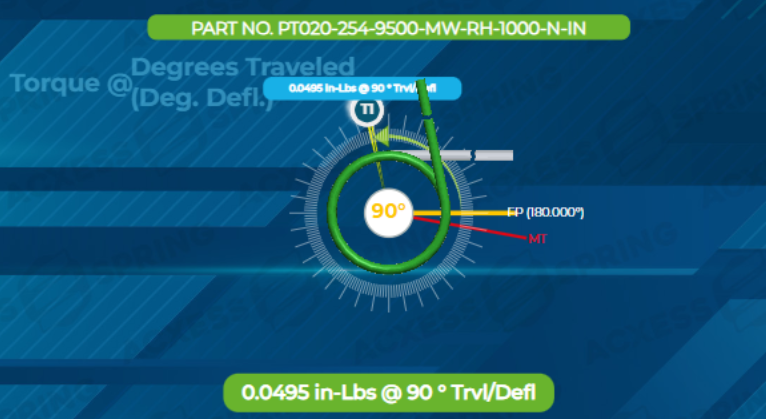

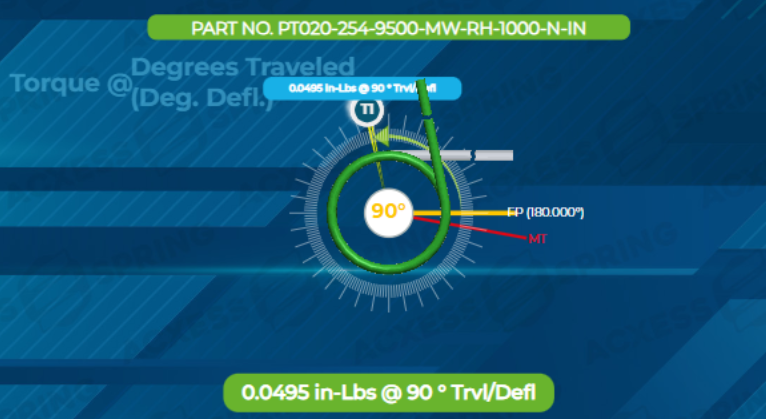

From the product view of Stock Part Number PT020-254-9500-MW-RH-1000-N-IN navigate to Online Spring Force Tester and input a Travel, or Deflection, of 90 degrees. The tool would automatically calculate the torque needed for that deflection.

Online Spring Force Tester shows that Stock Part Number PT020-254-9500-MW-RH-1000-N-IN needs 0.0495 in/lbs to travel to 90 degrees, matching the required torque and deflection for your application.

Result:

By following these steps, you find a spring that meets your torque requirements, fits the available space, and feels just right when opening and closing the small door.

General Tips for Step-by-Step Selection:

- Start with a Clear Specification: Know your torque requirements, available space, and environmental conditions before you begin searching.

- Leverage Online Tools: Spring finders like Spring Finder 5.0, load calculators like Spring Creator 5.0, and the Online Spring Force Tester save time and offer instant feedback.

- Don’t Be Afraid to Experiment: Especially during prototyping or replacement scenarios, ordering a few different springs and testing them out can be more cost-effective and quicker than getting stuck in lengthy analysis.

- Iterate and Adjust: If your first choice doesn’t feel right, use what you learned from testing to select a slightly different spring. This iterative approach often leads to the perfect solution faster.

By following these practical examples and the outlined steps, you can move confidently from theoretical parameters to a tangible, well-chosen torsion spring that meets the demands of your project.

Additional Considerations for Optimal Performance

Even after finding a suitable torsion spring , fine-tuning details can further enhance its performance and longevity:

- Surface Treatments: Beyond plating, consider shot peening or other surface treatments to improve fatigue life. These treatments compress the wire’s surface, making it more resistant to crack initiation and extending the spring’s operational life.

- Lubrication and Maintenance: In environments where friction is a concern, a light application of appropriate lubricant can reduce wear and noise. Regular maintenance checks help you spot issues early, replace worn springs proactively, and keep downtime minimal.

- Testing and Validation: For critical applications, consider validating your spring choice through testing. Testing under different loads can confirm that it meets the required performance before scaling up to production.

By addressing these finer points, you elevate your design from merely functional to truly optimized, ensuring long-term success and customer satisfaction.

Making Informed Purchasing Decisions

Stepping into an online spring catalog or speaking with a supplier can feel overwhelming if you’re not prepared. Here’s how to navigate the buying process confidently:

- Start with a Clear Specs List: Before browsing, compile essential data—required torque, deflection angles, maximum dimensions, environmental conditions, and budget constraints. This clarity helps you filter out unsuitable options quickly.

- Use Filtering Tools: When Spring Finder 5.0 shows the list with your results, filter through your wire diameter, inner diameter, coil count, or material preferences to immediately narrow down hundreds of options into a manageable shortlist.

- Review Technical Datasheets: Look for maximum torque, material properties, and maximum travel. Reputable suppliers often provide a blueprint with comprehensive data, so you can confirm that the spring will handle your application’s demands.

- Check Lead Times and Shipping Options: Even if a spring is in stock, you might need faster shipping or special packaging. Confirm that the supplier can meet your scheduling needs and provide rapid support if something goes wrong.

- Ask Questions: Don’t hesitate to reach out directly to the supplier’s technical support team. They can help clarify specs, recommend alternatives, or provide insights into how their springs have performed in similar applications.

Informed purchasing isn’t just about finding a spring that meets the basic requirements—it’s about finding a long-term partner that can support your evolving needs.

Partnering with a Reputable Supplier

Choosing a supplier is about more than just the product on the shelf; it’s about building a relationship that can support your projects from start to finish:

- Expert Guidance: Established suppliers often have engineers or technical experts on staff. Their insights can help you troubleshoot design challenges, pick the right materials, or calculate safe stress levels.

- Quality Assurance: A reliable supplier follows strict quality control measures, ensuring consistent products that meet published specifications. This reduces the risk of defective springs that cause costly rework or field failures.

- Customization When Needed: Even if you start with stock springs, it’s nice to know that your supplier can handle custom orders down the road. A full-service supplier streamlines your process by acting as a one-stop shop.

- Ongoing Support and Resources: Beyond the initial purchase, look for suppliers that provide educational content, calculators, or training. Staying updated with the latest best practices and innovations helps keep your products competitive.

- Strong Communication and Customer Service: If you run into an issue, it’s important to have a partner who’s responsive and reliable. Good communication accelerates problem-solving and helps maintain trust.

By partnering with a reputable supplier, you gain not only high-quality springs but also expert support, peace of mind, and a resource that can grow with your business.

How to Choose the Perfect Stock Small Torsion Springs for Reliable, Long-Lasting Performance?

Small torsion springs may often go unnoticed, tucked inside tiny hinges or concealed behind electronic covers, but their impact is profound. They bring precision, reliability, and a touch of finesse to countless mechanisms—from consumer gadgets to advanced medical instruments. With the right knowledge, tools, and partnerships, selecting the perfect stock small torsion spring becomes a straightforward, rewarding process.

5 Key Takeaways

- Stock Springs Deliver Speed and Savings: Leverage readily available in stock springs to jump-start prototyping, reduce lead times, and minimize upfront costs.

- Digital Tools Simplify Decision-Making: Utilize platforms like Spring Finder 5.0 and the Online Spring Force Tester for accurate calculations, simulations, and data-driven refinement.

- Know Your Requirements Inside and Out: Define your torque needs, deflection angles, space constraints, and environmental conditions before browsing catalogs to ensure a better match.

- Don’t Overlook Performance Enhancements: Consider stress reductions, corrosion-resistant finishes, surface treatments, and proper mounting to optimize longevity and reliability.

- Value Supplier Relationships: Work with reputable suppliers that offer technical expertise, quality assurance, customization capabilities, and ongoing support—making them a true partner rather than just a vendor.

Armed with these expanded insights and practical guidelines, you’re well-prepared to find, test, and implement the ideal small torsion spring for your unique application. With careful consideration, smart design, and the help of cutting-edge tools, you can ensure your final product runs smoothly, consistently, and for years to come.

Enhance your projects with Spring Creator 5.0

Precision is crucial in spring design, and with Spring Creator 5.0, you can achieve it with ease. Our tool allows you to design different types of springs and offers advanced features such as instant quotes and real-time simulations with the Online Spring Force Tester. Register now and access all the benefits of our platform. Create the perfect spring and take your projects to the next level!

Created by Alfonso Jaramillo Jr

President Acxess Spring

Over 40 Years of Experience in Spring Engineering and Manufacturing