Extension Springs Explained: A Comprehensive Guide for Innovators and Manufacturers

Extension Springs Explained: A Comprehensive Guide for Innovators and Manufacturers

Enter your Outer Diameter and Free Length

Hint: For larger search results, enter a bigger range of Min and Max Inputs

Enter your Outer Diameter and Length Inside Hook

Hint: For larger search results, enter a bigger range of Min and Max Inputs

Enter your Outer Diameter and Total Coils

Hint: For larger search results, enter a bigger range of Min and Max Inputs

Enter you Small Outer Diameter, Large Outer Diameter and Free Length

Hint: For larger search results, enter a bigger range of Min and Max Inputs

Table of contents

- What is a Stock Extension Spring?

- Core Attributes of Stock Extension Springs

- Stock Extension Spring End Types

- Stock Extension Spring Material Options

- How to Measure an Extension Spring

- How to Calculate Extension Spring Rate

- How to Calculate Your Extension Spring's Load

- How to Calculate Your Extension Spring's Initial Tension

- How to Calculate Your Extension Spring's Distance Traveled

- How to Calculate Your Extension Spring's Rate From Load and Travel

- Maximize Your Design with Spring Creator 5.0

- Empower Your Projects Today

What is a Stock Extension Spring?

A stock extension spring is a premade in-stock off the shelf mechanical spiral spring device designed to store and release energy through a pulling force. Unlike compression springs, which resist compressive force as they are compressed, extension springs are made to resist force when pulled apart. Typically made of round spring wire, these springs are helically wound, with the coils touching one another in their free, unstretched state. This compact stock extension spring configuration enables the spring to store a significant amount of energy called initial tension that's used when stretched. When the tension is released, the spring returns back to its original length, making extension springs ideal for applications that require controlled pulling forces or where energy must be absorbed and released.

Stock extension springs are commonly used in applications where tension is necessary to maintain a certain distance between two components. They’re found in everything from lightweight household products, like screen doors, to heavy-duty machinery in industries like construction and aerospace. Their ability to store and release energy consistently over repeated cycles makes them indispensable in many mechanical designs. At Acxess Spring, we believe that understanding the nuances of extension springs—from their physical properties to their specific applications—empowers innovators and manufacturers to create more reliable, efficient, and effective products.

Core Attributes of Extension Springs:

To fully appreciate the function of an extension spring, it's essential to understand its core physical attributes. These attributes influence how the spring behaves under load, and they are critical for selecting the right spring for any given application.

- Wire Diameter: This refers to the thickness of the wire used to make the spring. A larger wire diameter typically means the spring can handle more force, but it may be less flexible. Accurately measuring wire diameter is crucial, as even small variations can affect the spring's performance.

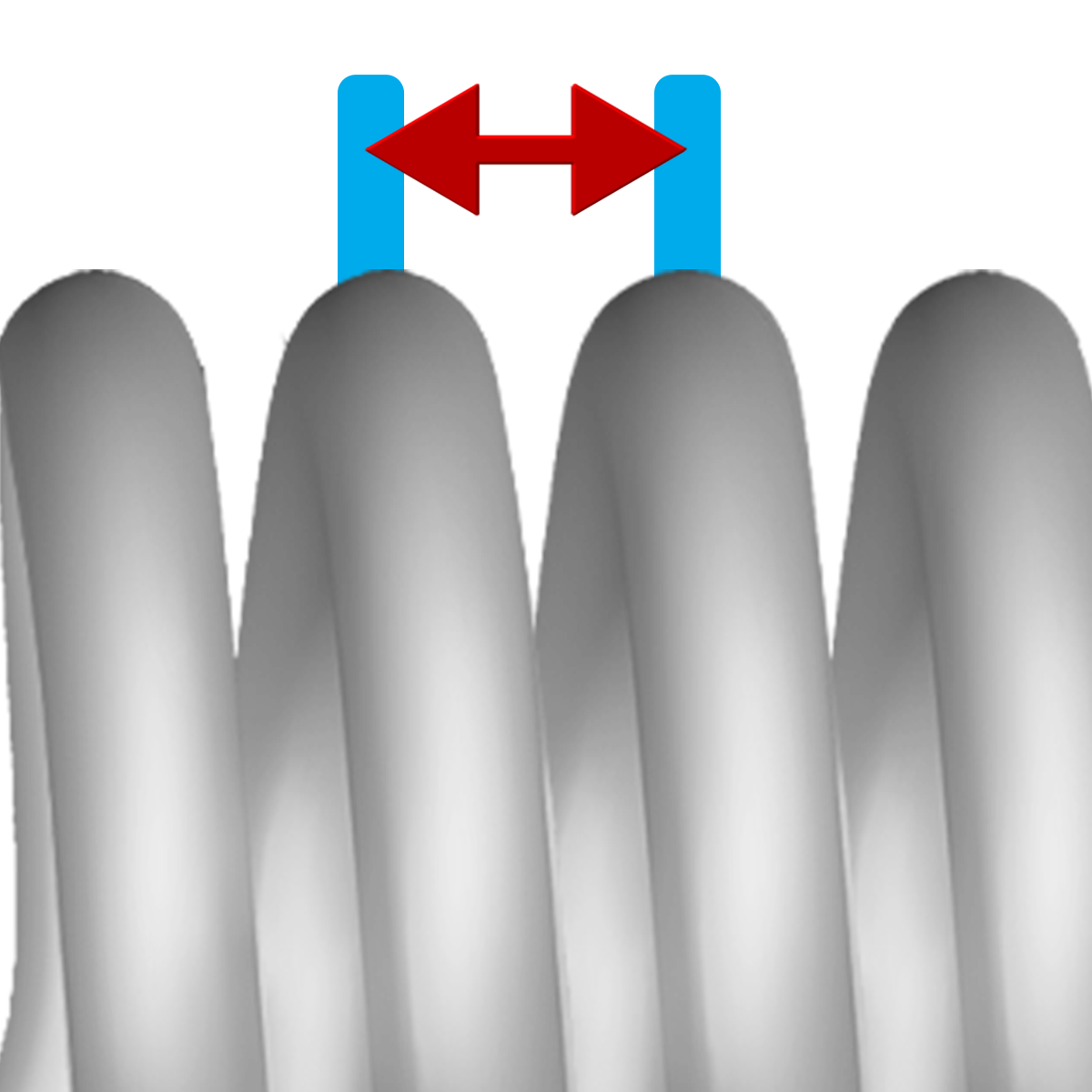

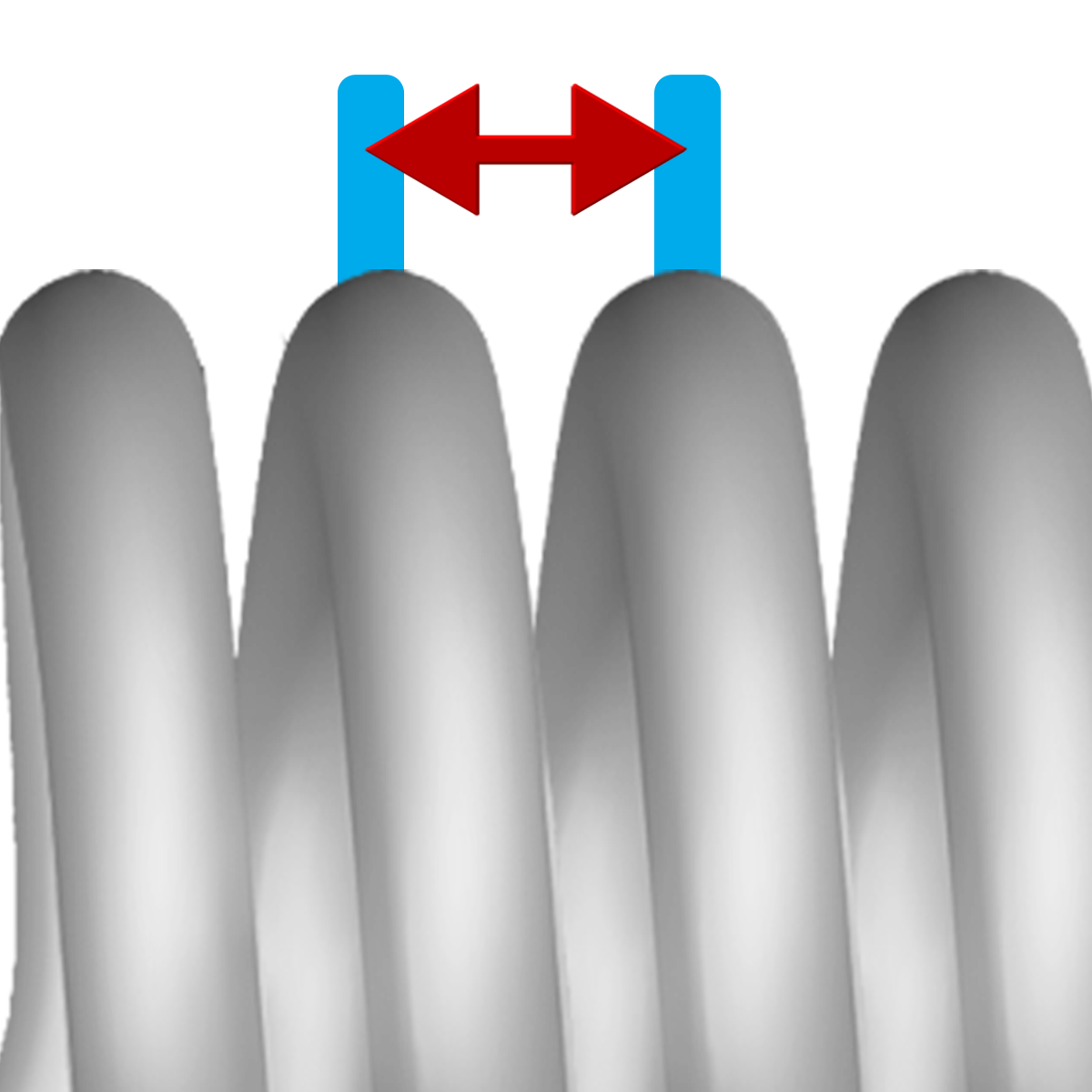

- Outer Diameter: The outer diameter is the measurement from the outside edge of one coil to the outside edge of the opposite side. It determines the overall diameter size of the spring and must be considered when fitting the spring into an assembly or housing.

- Inner Diameter: The inner diameter of the spring is the space inside the coils. It’s important when the spring needs to fit around another component, such as a rod or shaft. The inner diameter can be calculated by subtracting twice the wire diameter from the outer diameter.

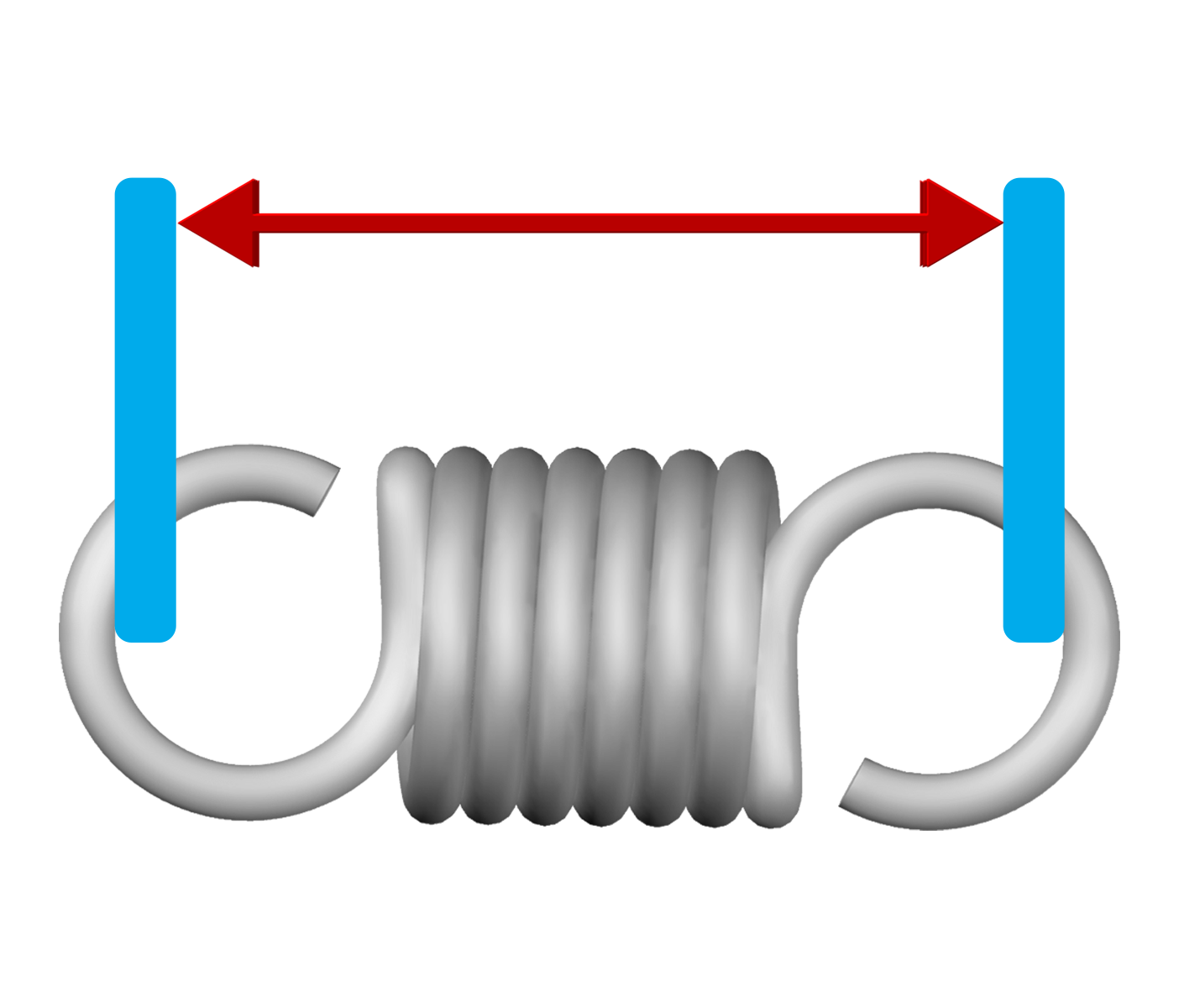

- Length Inside Hook: This refers to the distance between the inside ends of the hooks or loops, which impacts how the spring will connect to other components in an assembly. Measuring the length inside the hook ensures the spring will fit properly within the designated space and function as required. This measurement is crucial for proper attachment and to prevent overstressing the hook under load.

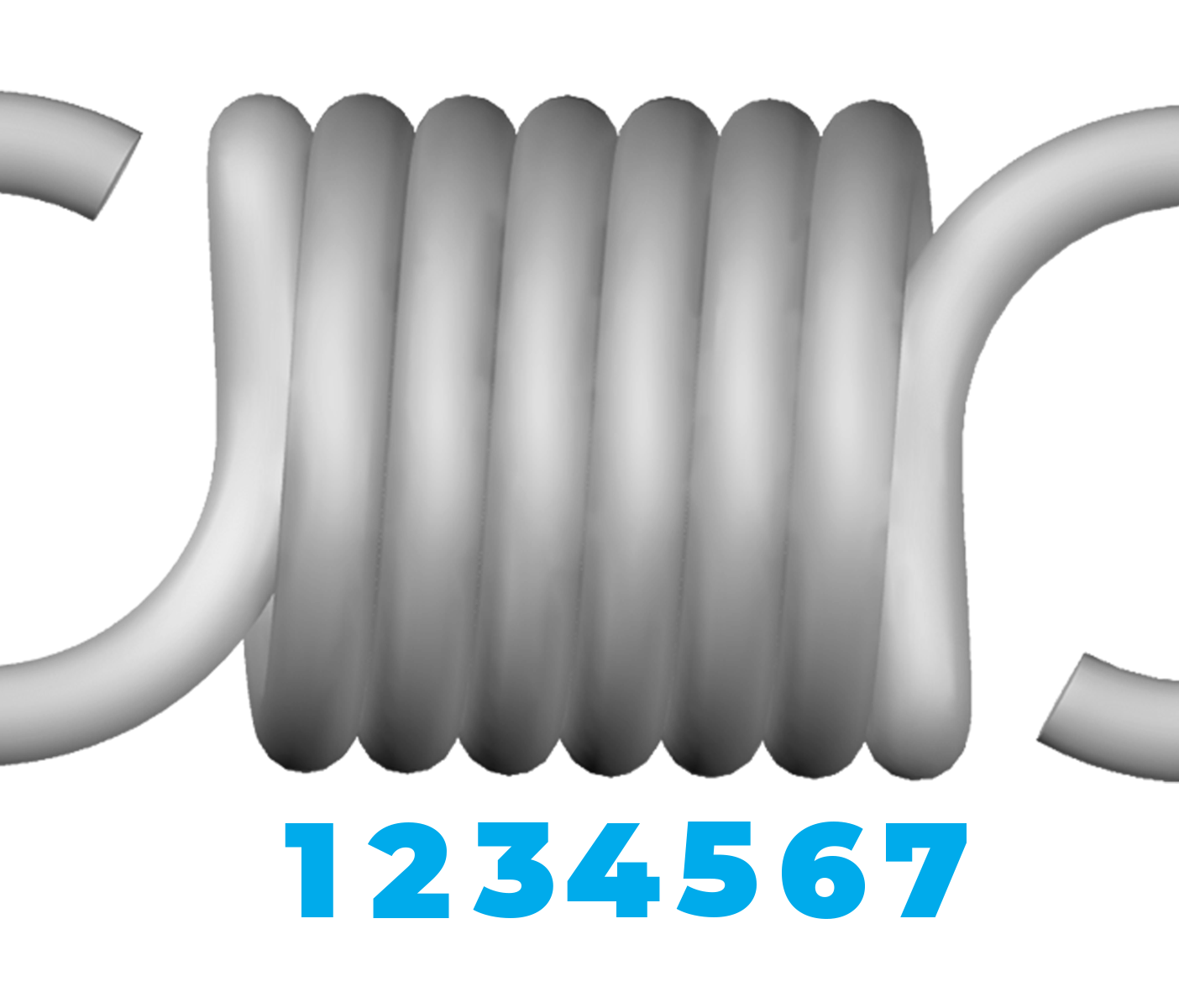

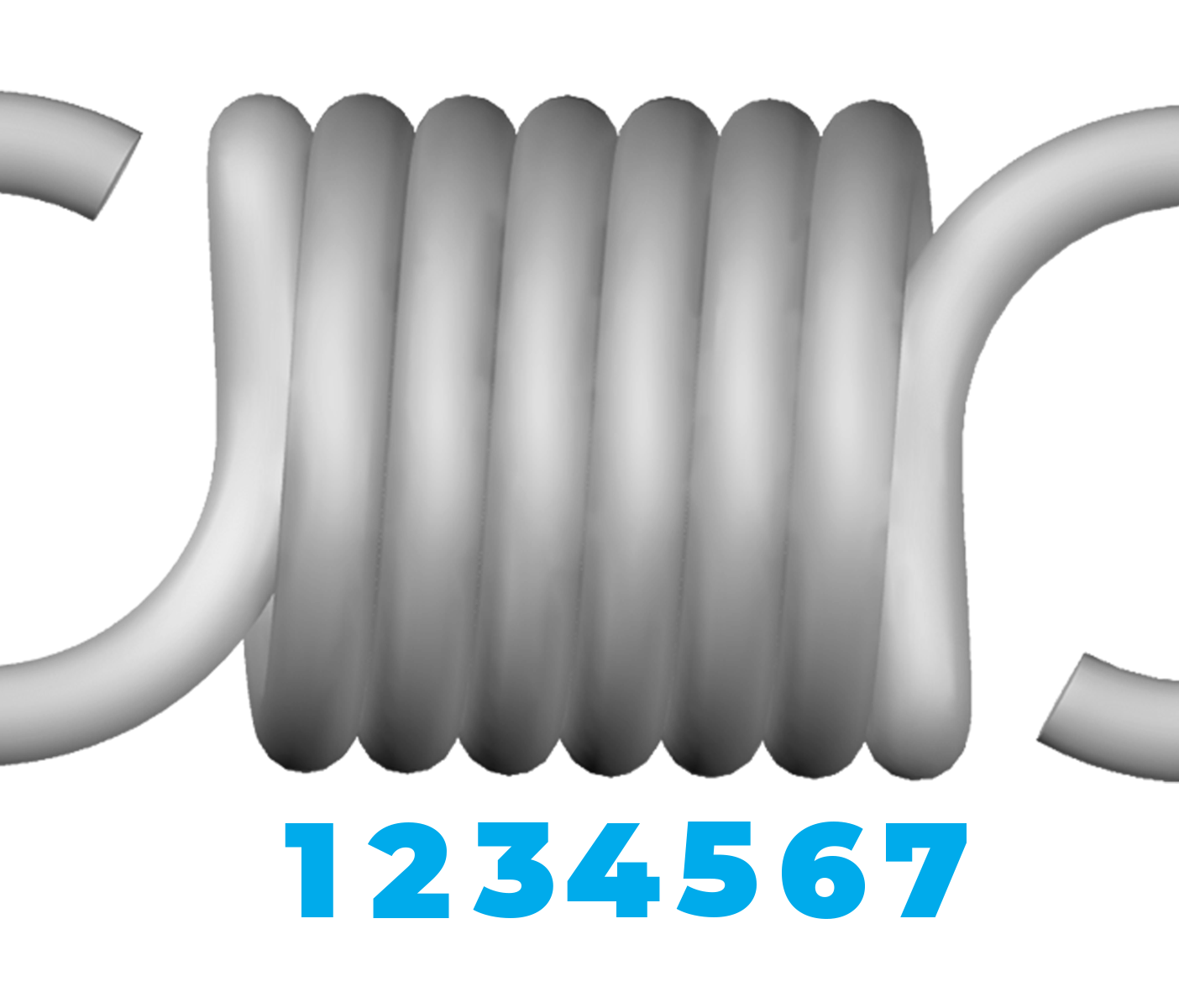

- Total Coils: This refers to the number of coils or loops that make up the spring body. The number of coils affects the spring's stretchability and the amount of energy it can store. More coils generally mean more flexibility and a lower spring rate (the force needed to stretch the spring). Less coils generally means a higher force with less stretch.

- Initial Tension: Unlike compression springs, extension springs have an initial tension built into them, which keeps the coils tightly wound even when no load is applied. This initial tension must be overcome before the spring begins to extend. Initial tension is sandwiched in-between the stacked number of coils. When one extends the extension spring, the initial tension force is used first before the spring rate kicks in. One must add this initial tension force to the normal spring rate k to correctly calculate the total spring force load.

Extension Spring End Types

The end type of a stock extension spring is a crucial feature that determines how it attaches to other components in an assembly. The ends form either hooks or loops, which are essential for allowing the spring to latch onto a rod or fixture to stretch and return to its original pre-loaded state. These end types vary in strength, durability, and specific use cases, depending on the requirements of the application. Below are the common types of hooks used for extension springs:

- Machine hooks are one of the most commonly used end types for extension springs, offering strength and reliability across a wide range of applications. These hooks are made by bending about ¾ of a coil out, which provides a solid and stable connection point. The radius of the bend in machine hooks is less pronounced than in other types of hooks, which enhances their durability and allows them to withstand more force. Because of their robust construction, machine hooks are often used in heavy-duty applications where higher loads and repeated pulling cycles are involved. This design ensures that the spring will function efficiently without premature wear or failure.

-

Cross Over Center Hooks: Another widely used end type is the cross over center hook, which features more pronounced bends compared to machine hooks. These hooks are made by lifting the last coil and twisting it towards the center of the spring, crossing over the middle. This design provides a versatile attachment point, especially when the spring needs to remain centrally aligned within an assembly. Cross over center hooks are slightly less complex to manufacture than machine hooks, and they offer a reliable and secure connection. They are ideal for applications where precise alignment and controlled tension are required, as the crossing hook design helps distribute the force more evenly across the spring.

-

Side hooks are designed for situations where the spring body must avoid interfering with other components in a mechanism. In this configuration, the hooks are placed on one side of the spring, which offsets the rest of the spring from the components it connects to. This is a practical and economical solution, as side hooks are created by simply bending the last coil out. The simplicity of the design makes side hooks more cost-effective to manufacture than cross over center hooks, yet they still provide reliable functionality. They are commonly used in applications where space is limited, or the spring must remain unobstructed during operation.

-

Extended hooks serve a similar function to side hooks, but with an added advantage: they allow for a longer length inside hook while maintaining a short body length. This design is beneficial when more distance between the body of the spring and the end of the hook is needed, making the spring more efficient in applications requiring more space to place the spring hook into a product. However, because of the complexity in creating extended hooks, they are the most expensive hook type. These hooks are often chosen when the spring needs to provide significant force while fitting into a confined space. Extended hooks are useful in precision applications where both strength and space conservation are priorities.

-

No Hooks: Some extension springs are designed with no hooks at all, which offers several unique advantages. By eliminating hooks, the spring avoids the stress and fatigue that typically occur at the hook ends, significantly increasing the spring’s lifespan. Springs without hooks are also the most economical to manufacture, as they simplify the design and production process. Without hooks, the spring's pulling force and distance can be increased, making it capable of handling larger loads and longer cycles of life. Additionally, the absence of hooks allows for alternative attachment methods, such as threading a bolt into the inner diameter of the spring. This can securely fasten the spring without the risk of hook breakage, making no-hook springs an ideal choice for high-stress or high-cycling applications.

Extension Spring Material Options:

Like all mechanical components, the performance and durability of an extension spring depend significantly on the material from which it is made. Different materials offer various levels of strength, corrosion resistance, and flexibility, making it important to choose the right one for your application.

-

Music Wire ASTM A228: This is a highly durable and reliable material often used for extension springs in high-stress environments. Its excellent tensile strength and fatigue resistance make it ideal for applications requiring precision and repeated use, such as in industrial machinery or precision instruments.

-

Stainless Steel ASTM A313: Stainless steel is known for its excellent resistance to corrosion, making it a great choice for extension springs used in environments where moisture, chemicals, or other corrosive elements are present. Its longevity and resilience also make it a top choice for springs used in medical devices, food processing equipment, and marine applications.

-

Hard Drawn ASTM A227: A more cost-effective material, hard drawn wire is suitable for applications that do not require significant resistance to corrosion or extreme loads. It’s commonly used in everyday products and in industrial machinery where budget constraints are important.

In addition to these common materials, Acxess Spring offers extension springs in specialized materials such as Beryllium Copper, Phosphor Bronze, and Chrome Silicon, providing solutions for specific environmental and operational challenges. These materials are used in applications ranging from high-heat environments to highly conductive settings.

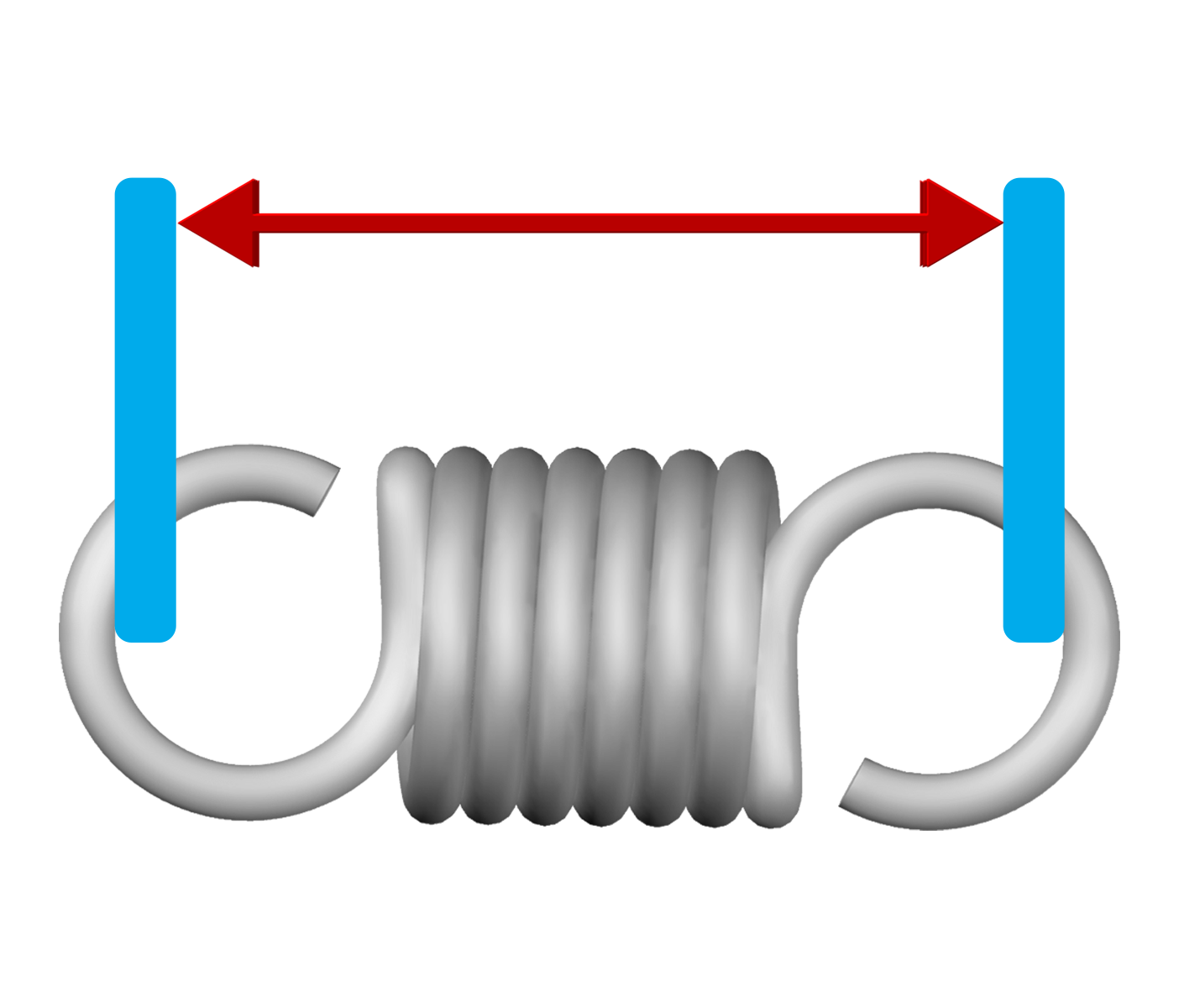

How to Measure an Extension Spring:

Proper measurement is crucial to ensure that an extension spring fits and functions as intended in its application. Here’s how to measure the key dimensions of an extension spring:

- Wire Diameter (WD): The thickness of the spring wire is one of the most important measurements. To measure the wire diameter, use a digital caliper and place it around the wire to get an accurate reading. Small variations in wire diameter can significantly impact the spring’s performance.

- Outer Diameter (OD): This is the distance across the outermost part of the spring coil. To measure it, use a caliper to measure from one side of the coil to the opposite side at its widest point. This ensures that the spring will fit properly in the housing or space it is intended for.

- Free Length (FL): The free length is the total length of the spring, including the coils and any hooks or loops. To measure this, stretch the spring gently so that it is not under load, and use a ruler or caliper to measure from one end of the spring to the other.

- Total Coils (TC): Count the number of full coils in the spring, excluding any that form the hooks or loops. The number of coils affects the spring’s tension and overall flexibility, so this is an important factor to consider.

- Hook Type: Measure the length and shape of the spring’s hooks or loops to ensure they will fit within your assembly. Different hook types provide different levels of strength and durability, so this is crucial for selecting the right spring.

Accurate measurement ensures the extension spring will fit and perform as needed, preventing malfunctions or premature wear in your application.

How to Calculate Extension Spring Rate:

The spring rate (k), or spring constant, of an extension spring is a measure of how much force is required to extend the spring by a given distance. Understanding this value is critical when designing or selecting a spring for a particular application, as it helps determine how the spring will behave under load.

The formula for calculating the spring rate is:

k = Gd^4 ÷ (8D^3 * n)

Where:

- G is the modulus of rigidity of the spring material (a measure of the material’s stiffness),

- d is the wire diameter,

- D is the mean coil diameter (the average of the inner and outer diameters),

- N is the number of active coils.

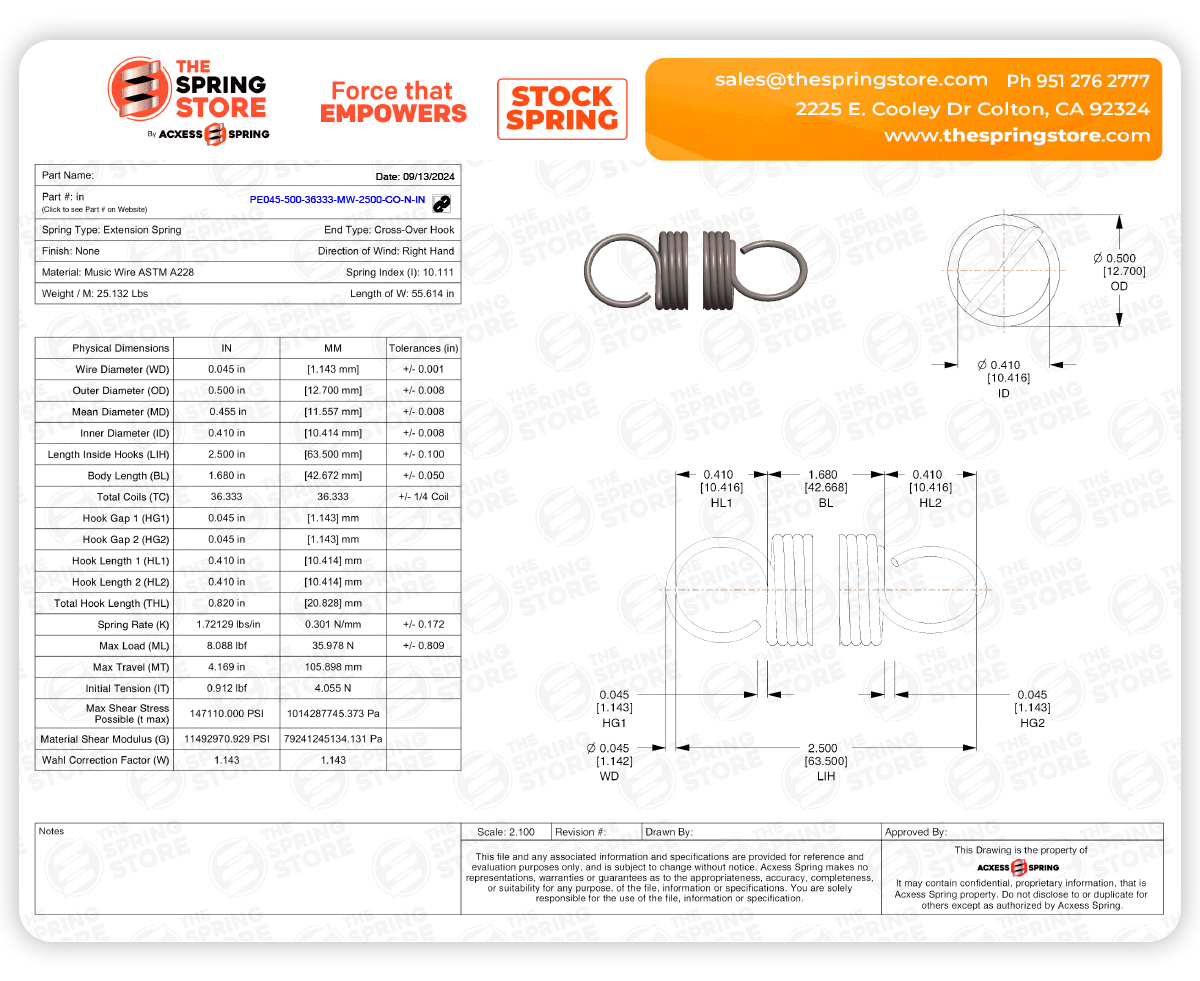

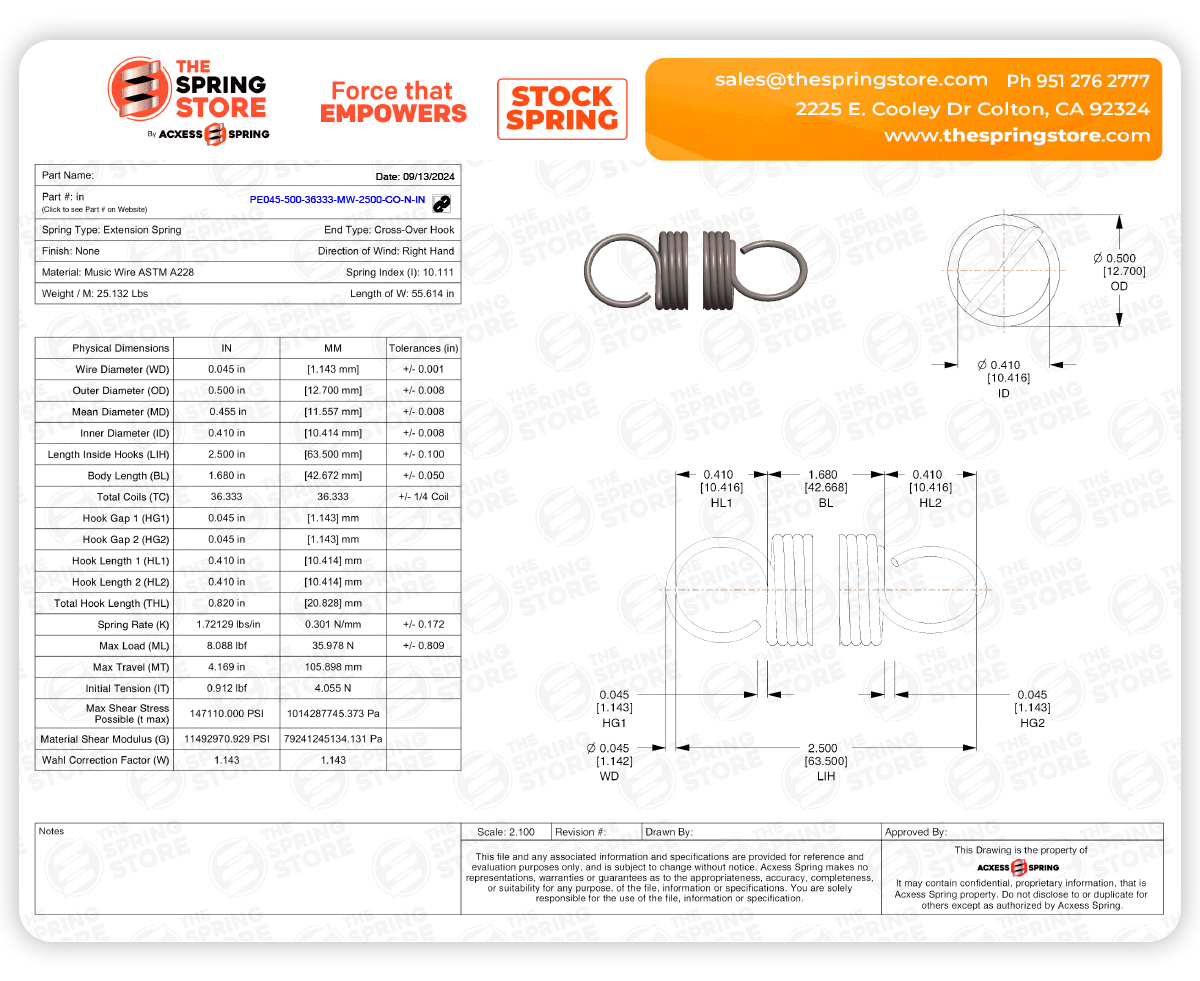

For example, on Axcess Spring’s Part number PE045-500-36333-MW-2500-CO-N-IN where wire diameter is 0.045 inches, the mean diameter is 0.455 inches, has a material shear modulus (G) of 11492970.929 ps and counts with 36.33 total coils, the formula would be solve like this:

| Part Number | PE045-500-36333-MW-2500-CO-N-IN |

| Wire Diameter (d) | 0.045 inches |

| Mean Diameter (D) | 0.455 inches |

| Total Coils (n) | 36.33 |

| Material Shear Modulus (G) | 11492970.929 psi |

- Step 1: Calculate d^4

- First, we raise the wire diameter d to the power of 4:

- d^4 = 0.045^4 = 0.000004100625 inches

- Step 2: Calculate D^3

- Next, we raise the mean diameter D to the power of 3:

- 3D^3 = 0.455^3 = 0.094196375

- Step 3: Multiply the results by the number of coils and constants

- Now, multiply the D^3 value by 8 and the total number of coils n:

- 8 ⋅ D^3 ⋅ n = 8 ⋅ 0.094196375 ⋅ 36.33 = 27.37723443

- Step 4: Multiply G by d^4

- Now, multiply the shear modulus G by d^4:

- G ⋅ d4 = 11492970.929⋅ 0.000004100625 = 47.12836391573063

- Step 5: Divide the results

- Finally, divide the result from Step 4 by the result from Step 3 to get the spring rate k:

- k = 47.12836391573063 ÷ 27.37723443 = 1.721 lbs/in

- The spring rate is approximately 1.721 lbs/in.

This calculation provides a quantitative measure of the spring’s stiffness. A higher spring rate means that more force is required to stretch the spring, while a lower spring rate indicates a more flexible spring. Understanding the spring rate allows engineers to select or design a spring that will meet the specific requirements of their application, ensuring it performs reliably over time.

How to Calculate Your Extension Spring's Load

The load that an extension spring can handle is an essential factor in determining its performance within an application. To calculate the load, you begin by multiplying the spring’s Rate (R) by the Distance Traveled (DT), which is the amount you expect the spring to extend under a given force. The formula for this calculation is straightforward:

Rate × Distance Traveled = Load

Or more specifically:

R × DT = L

If we need to calculate the load for Axcess Spring’s Part number PE045-500-36333-MW-2500-CO-N-IN traveling to a distance of 2.5 inches with a spring rate of 1.72129 lbs/in, we’ll do the following calculation:

R × DT = L

1.72129 x 2.5 = 4.303225

This means that if you know how much the spring will stretch and the spring’s rate (which is a measure of its stiffness), you can calculate the load it will experience, in this case 4.303225 lbf. However, this is only part of the equation. Most extension springs have an initial tension—a pre-loaded tension that needs to be overcome before the spring begins to extend, for Part number PE045-500-36333-MW-2500-CO-N-IN the initial tension is 0.913 lbf. Therefore, once you have the calculated load from the above formula, you must add the initial tension to get the true load at a specific distance traveled. This gives you a more accurate idea of the total force the spring will experience during operation, helping to ensure that it will meet the performance and safety requirements of your application. Now let’s calculate the load adding the initial tension:

L + IT

4.303225 + 0.913 = 5.216 lbf

How to Calculate Your Extension Spring's Initial Tension

Initial tension refers to the force that is built into an extension spring in its coiled, unloaded state. Unlike compression springs, which begin resisting force as soon as they are compressed, extension springs require this initial tension to be overcome before any elongation occurs. Calculating the initial tension is crucial for understanding how much force is required to start extending the spring and whether the spring will be able to handle the operational loads.

The formula for calculating initial tension is as follows:

P = S × d^3 ÷ 2.55 × D

Where:

- P is the load or force in pounds (lbs),

- S is the stress (lbs per square inch) in the spring,

- d is the wire diameter of the spring,

- D is the mean coil diameter.

This formula helps you determine how much tension is "sandwiched" between the coils before the spring is even extended. The wire diameter and mean coil diameter are critical factors in this calculation, as they affect the spring's ability to store and release energy. A higher initial tension means the spring will require more force to begin extending, which is important to consider for applications where precise tension control is needed.

Maximize Your Design with Spring Creator 5.0

Spring Creator 5.0 from Acxess Spring is an innovative, user-friendly tool that simplifies the design and selection of extension springs. This powerful platform is designed to streamline the spring design process, providing professionals with the tools they need to make informed decisions quickly.

- Instant Calculations: With Spring Creator 5.0, you can input key parameters like wire diameter, number of coils, and material type to instantly calculate critical metrics such as spring rate, maximum load capacity, and total deflection. This allows for quick adjustments to ensure that the spring meets your exact specifications.

- 3D Visualization: One of the standout features of Spring Creator 5.0 is its ability to generate real-time 3D models and blueprints of the spring. This visual aid helps engineers and designers see how the spring will look and function within their assembly, making it easier to ensure that the spring fits and performs as intended.

- Online Spring Force Tester: The platform also includes a real-time spring force tester, allowing you to simulate how your extension spring will perform under different loads. This animation shows how much force the spring can handle and how much it will stretch before reaching its limit, ensuring that your design meets both functional and safety requirements.

- Cost Estimation: Another valuable feature is the cost estimation tool, which helps you determine the cost of your spring design early in the process. This allows for more efficient budgeting and helps align your design with cost constraints.

With Spring Creator 5.0, you can enhance your extension spring designs with precision, efficiency, and ease, making it the ultimate tool for both seasoned engineers and innovators just starting out.

Empower Your Projects Today

At Acxess Spring, we are dedicated to providing high-quality, custom, and stock extension springs for all types of applications. Whether you're developing a cutting-edge medical device, designing industrial machinery, or creating innovative consumer products, our extensive catalog and the powerful tools we offer, like Spring Creator 5.0, ensure that you’ll find the perfect spring for your needs.

We offer a wide selection of extension springs in various materials, sizes, and end types, as well as the option to fully customize your springs to meet the unique demands of your project. By partnering with Acxess Spring, you gain access to decades of expertise, top-tier manufacturing standards, and the innovative tools you need to bring your vision to life.

Empower your projects with precision-engineered springs that deliver reliability, performance, and durability—every time.

Enhance your projects with Spring Creator 5.0

Precision is crucial in spring design, and with Spring Creator 5.0, you can achieve it with ease. Our tool allows you to design different types of springs and offers advanced features such as instant quotes and real-time simulations with the Online Spring Force Tester. Register now and access all the benefits of our platform. Create the perfect spring and take your projects to the next level!

Created by Alfonso Jaramillo Jr

President Acxess Spring

Over 40 Years of Experience in Spring Engineering and Manufacturing