Replacement Springs

The Ultimate Guide to Replacement Springs

What Are Replacement Springs?

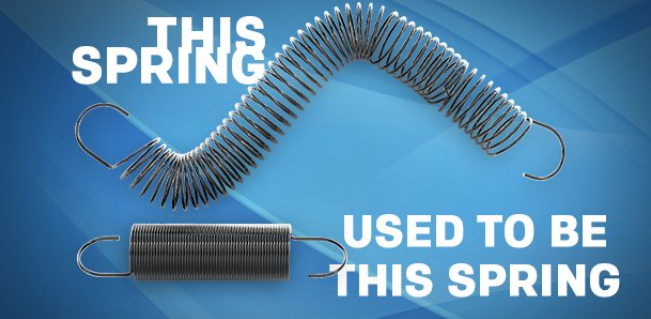

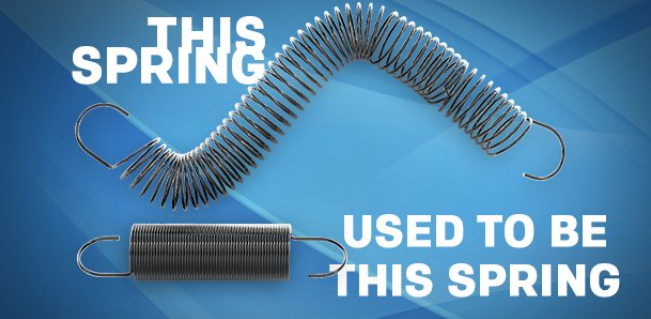

Replacement springs step in when the original spring in your device can’t do its job anymore. They’re available in a bunch of types like compression springs, extension springs, torsion springs, and cone springs. Each type has a specific role—resisting pressure, absorbing energy, or storing potential energy for movement. For example, compression springs are great for absorbing shock, while torsion springs twist to generate rotational energy.

Over time, springs can wear out from stress, rust, or just plain old age. When that happens, the right replacement spring is key to keeping your gadget or mechanism working properly. A worn-out spring can lead to bigger problems if not replaced in time, so it’s best to act quickly. You can design a custom spring from the dimension of your original spring, or check out The Spring Store, which offers over 42,000 ready-to-ship options, including steel springs and small coil springs. With their tools, like the Spring Finder, you’ll save time and effort while finding a perfect fit for your needs.

Key Characteristics of Springs

Understanding your spring’s key characteristics is like knowing the recipe for your favorite dish. Get the basics right, and you’re good to go! Let’s break down the essential details that make up a spring and how they affect its performance.

1. Spring Dimensions:

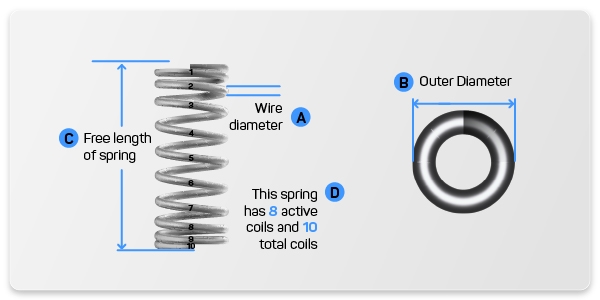

Dimensions are the first thing to consider when replacing a spring. They’re the physical measurements that determine if a spring will fit properly in your device:

- Outer Diameter (OD): This is how wide the spring is at its widest point. It’s crucial for fitting into housings or spaces. A spring that’s too wide might not fit, while one that’s too narrow could wobble.

- Inner Diameter (ID): The narrowest measurement, especially important if the spring needs to slide over a rod or shaft. This ensures a snug fit without being overly tight.

- Wire Diameter: How thick the wire is. This affects how strong the spring is and how it behaves under load. Thicker wires make for stronger, stiffer springs.

- Free Length: The length of the spring when it’s not compressed or stretched. Knowing this helps ensure it fits your device when it’s at rest. A spring that’s too long or short might not work as intended.

2. Load and Deflection:

Load and deflection describe how a spring behaves when force is applied. This is all about performance:

- Load: The amount of force applied to the spring. Matching this with your needs is key to avoiding overloading the spring. If a spring can’t handle the load, it may deform or break.

- Travel Deflection: How much the spring moves when a load is applied. Too much deflection can mean the spring won’t bounce back properly, while too little might indicate it’s too stiff for the job.

Understanding load and travel deflection ensures your spring performs as expected, whether it’s holding up a garage door or providing tension in a small mechanism.

3. Rate:

Think of the spring rate, also known as spring constant, as its personality—how stiff or flexible it is. It’s the force needed to compress or stretch the spring a certain distance. The rate is critical for ensuring the spring responds correctly to force.

Formula: Rate = Load / Deflection

For example, light extension springs will have a lower rate, making them easy to stretch, while heavy-duty springs used in trailer ramps require a higher rate to handle heavy loads. Understanding the rate helps you choose a spring that’s just right for your needs—not too stiff, not too soft.

4. Material Type:

The material of your spring determines its durability and where it can be used. Different materials excel in different environments:

- Music Wire ASTM A228: Strong and elastic, great for high-stress uses like piano strings or industrial applications.

- Stainless Steel 302 ASTM A313: Resistant to rust, making it ideal for outdoor or wet environments like marine equipment.

- Phosphor Bronze ASTM B159: Perfect for electrical applications due to its conductivity and resistance to wear.

Picking the right material ensures your spring can handle the job and stay durable for the long haul. For example, trailer gate assist springs often need stainless steel for outdoor durability.

Practical Considerations When Choosing Replacement Springs

Choosing a replacement spring doesn’t have to be complicated. By keeping a few practical tips in mind, you can find the perfect spring for your needs without breaking a sweat. Let’s take a deeper dive into what you should consider:

1. Match Dimensions and Performance:

The first step is ensuring the replacement spring has the same dimensions as the original. Check the outer diameter, inner diameter, wire thickness, and free length to avoid compatibility issues. But don’t stop there! Make sure the performance specs—like load and deflection—match, too. For example, if your spring operates under high load, a mismatch could lead to failure or wear. On the flip side, for lighter-duty applications, an overly stiff spring could hamper performance.

2. Think About the Environment:

Where the spring will be used plays a big role in your choice. For outdoor applications, corrosion resistance is essential, so Stainless Steel 302 ASTM A313 is a go-to option. In high-heat situations, such as automotive or industrial uses, materials like Stainless Steel 17-7 PH ASTM A313 are better equipped to withstand the stress. Humid environments, marine settings, or exposure to chemicals might require specialized coatings or non-corrosive metals.

3. Focus on Longevity:

No one wants to keep replacing the same spring over and over. Opt for materials and finishes that are designed to last. Protective coatings can add years to your spring’s life, especially in demanding conditions. For example, a spring metal with a zinc coating can resist rust and wear, even in harsh outdoor environments. Also, consider the frequency of use—springs in constantly moving parts will need to handle repeated cycles without losing strength or elasticity.

4. Test Before Installing:

Before committing to a replacement spring, testing is a must. Tools like the Online Spring Force Tester allow you to measure the spring’s load and deflection and see if your spring works within the maximum load and maximum travel. This ensures you’re not just hoping the spring will work but confirming it will. Testing also helps prevent issues like underperformance or overstress once the spring is installed.

5. Account for Tolerances:

Every spring has a tolerance range—a small margin of error in its dimensions and performance. When replacing a spring, make sure these tolerances align with your device’s needs. A spring with overly tight tolerances might be unnecessarily expensive without adding any real benefits. Conversely, loose tolerances could result in poor performance or even damage to the device.

6. Don’t Overlook Compatibility with Adjacent Components:

Springs rarely work in isolation; they’re part of a system. When replacing a spring, consider how it interacts with other parts like rods, hooks, or levers. A spring that fits perfectly, but rubs against nearby components, might cause wear or noise over time. Check clearances and ensure smooth operation within the entire mechanism.

Using Spring Finder 5.0

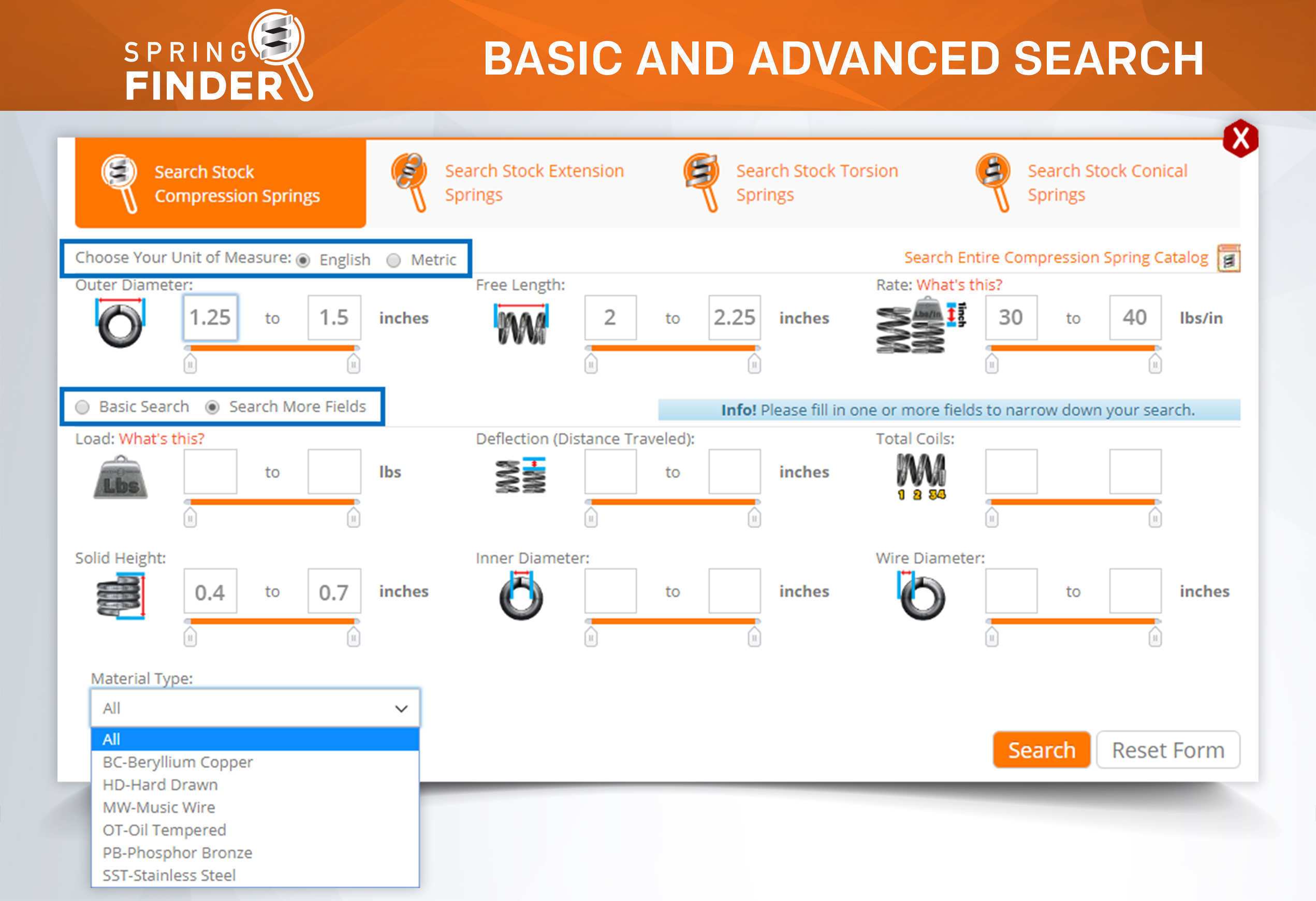

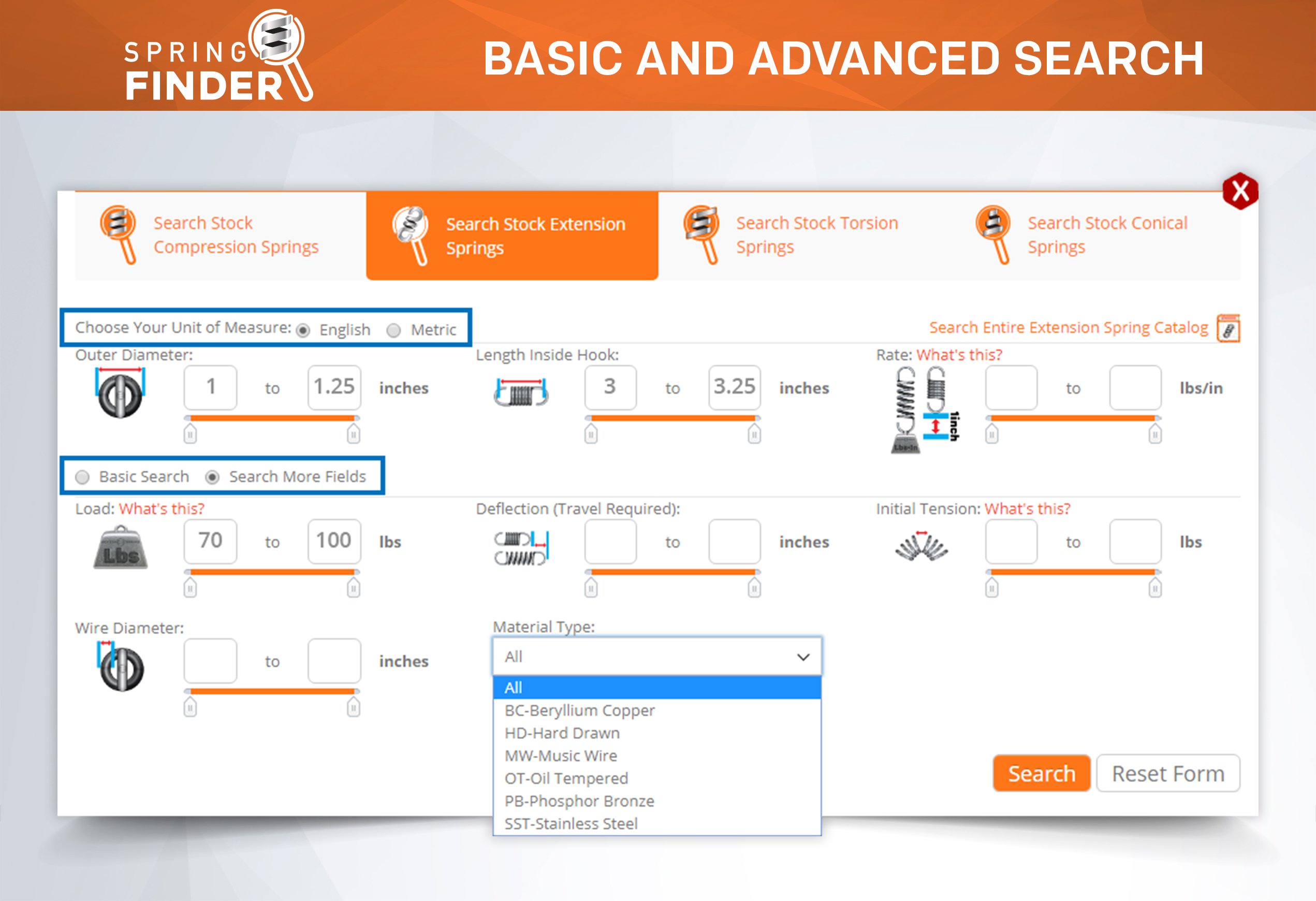

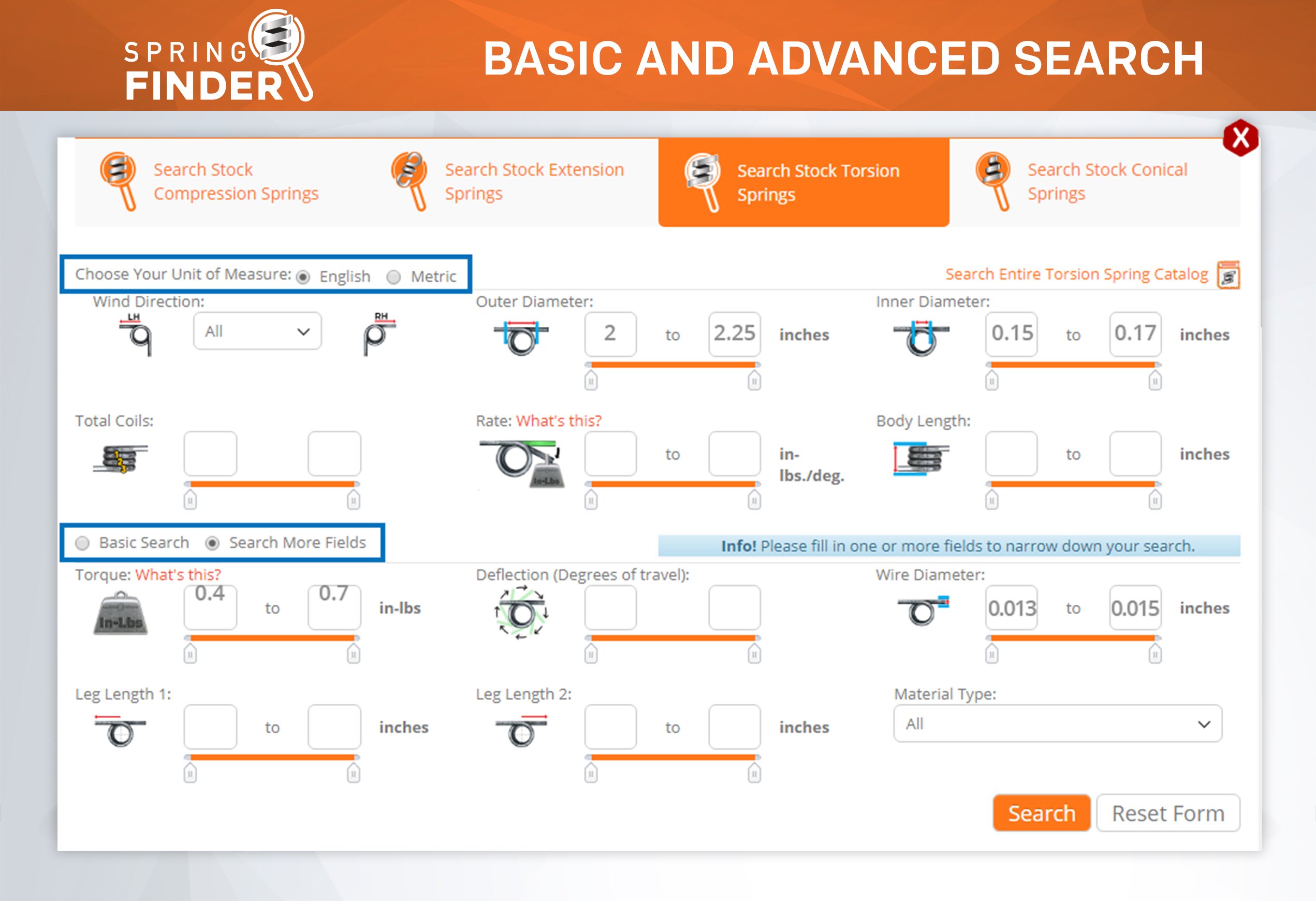

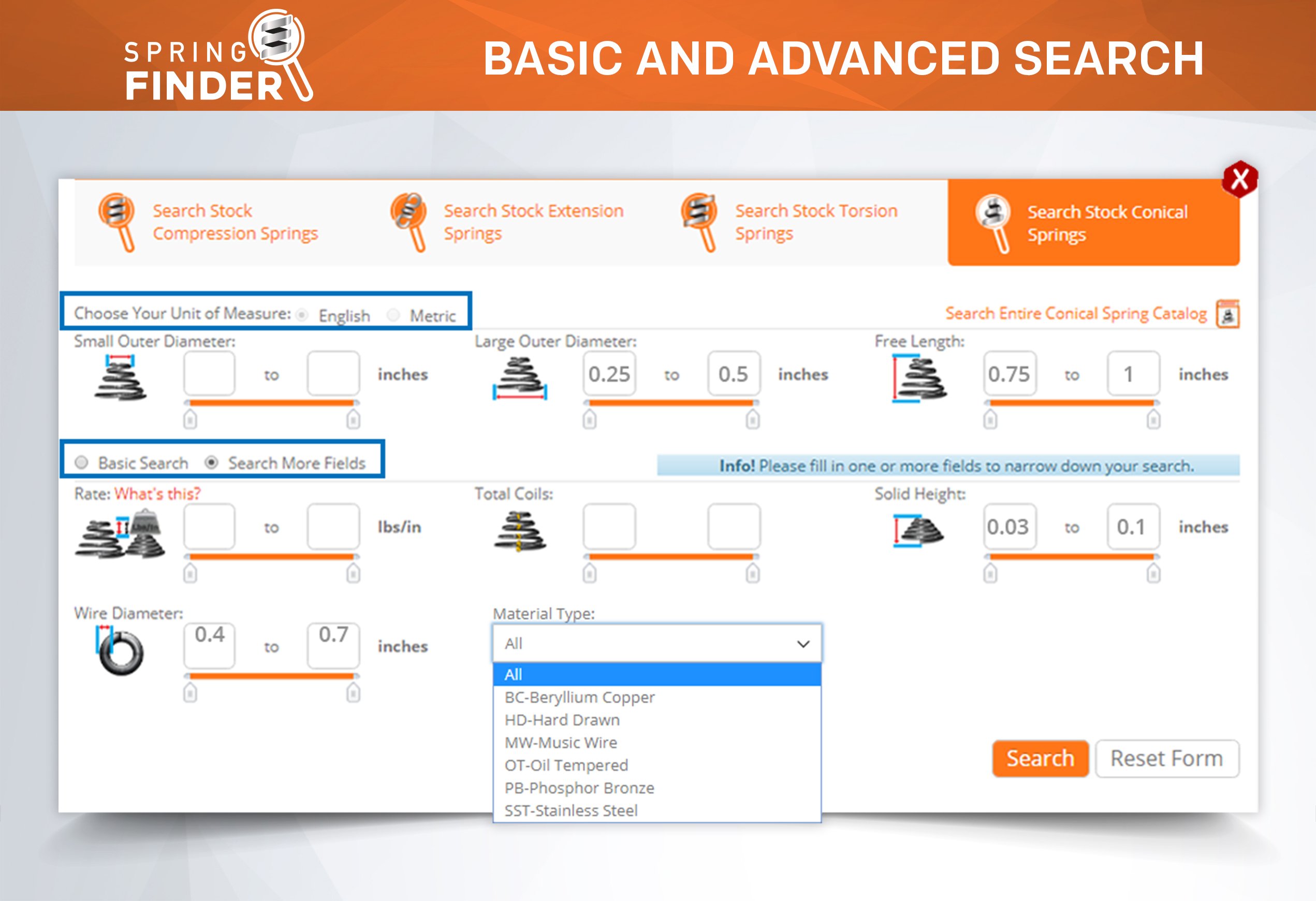

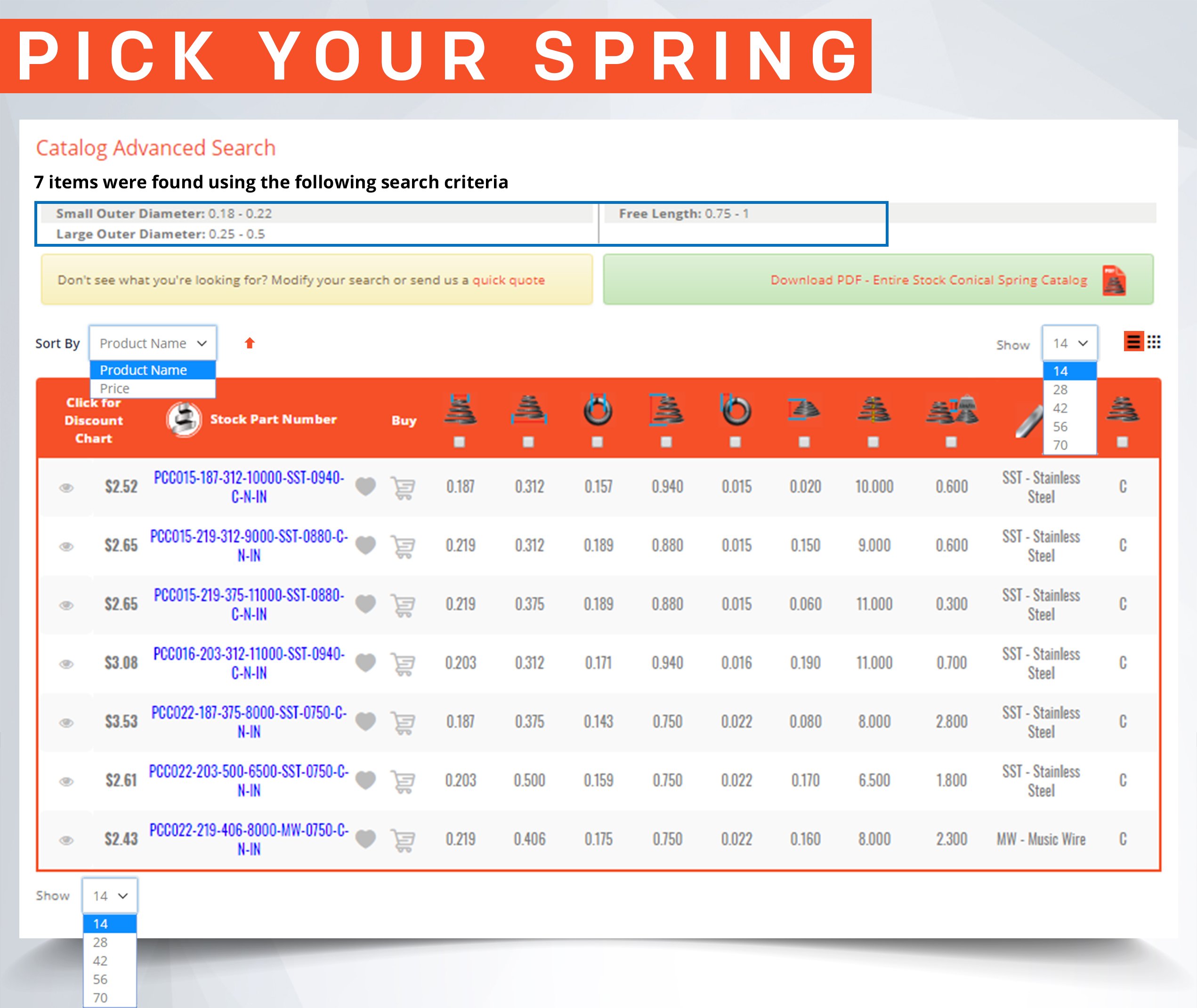

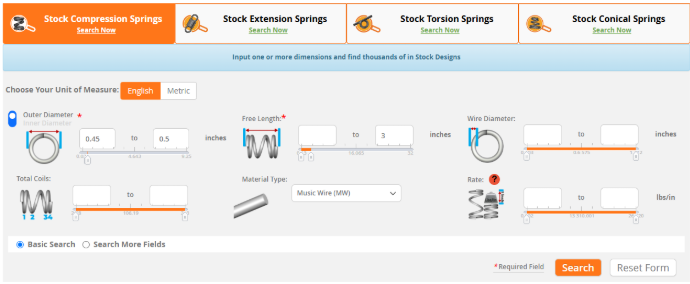

Let’s walk through an example of how to use Acxess Spring’s Spring Finder 5.0 to find the perfect replacement spring:

Step 1: Access the Tool

Start by visiting The Spring Store website and locating the "Spring Finder 5.0" tool. Open it to begin your search.

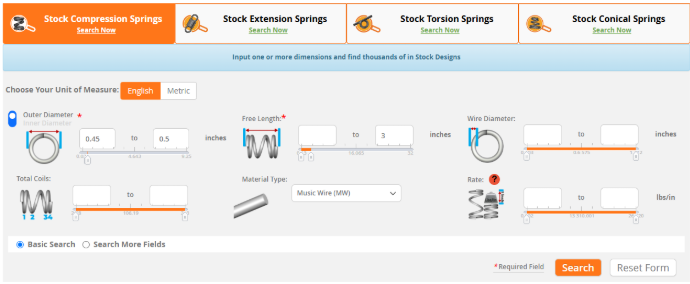

Step 2: Enter Your Specifications

Input the basic dimensions of the spring you need, such as outer diameter, inner diameter, free length, and wire diameter. For this example, we’ll search for a spring replacement for a spring with an outer diameter of 0.5 inches and a free length of 3 inches that can hold a force of 10 lbf at a distance traveled of around 1.5 inches. Don’t forget to choose the material based on the environment—stainless steel for corrosion resistance, for example.

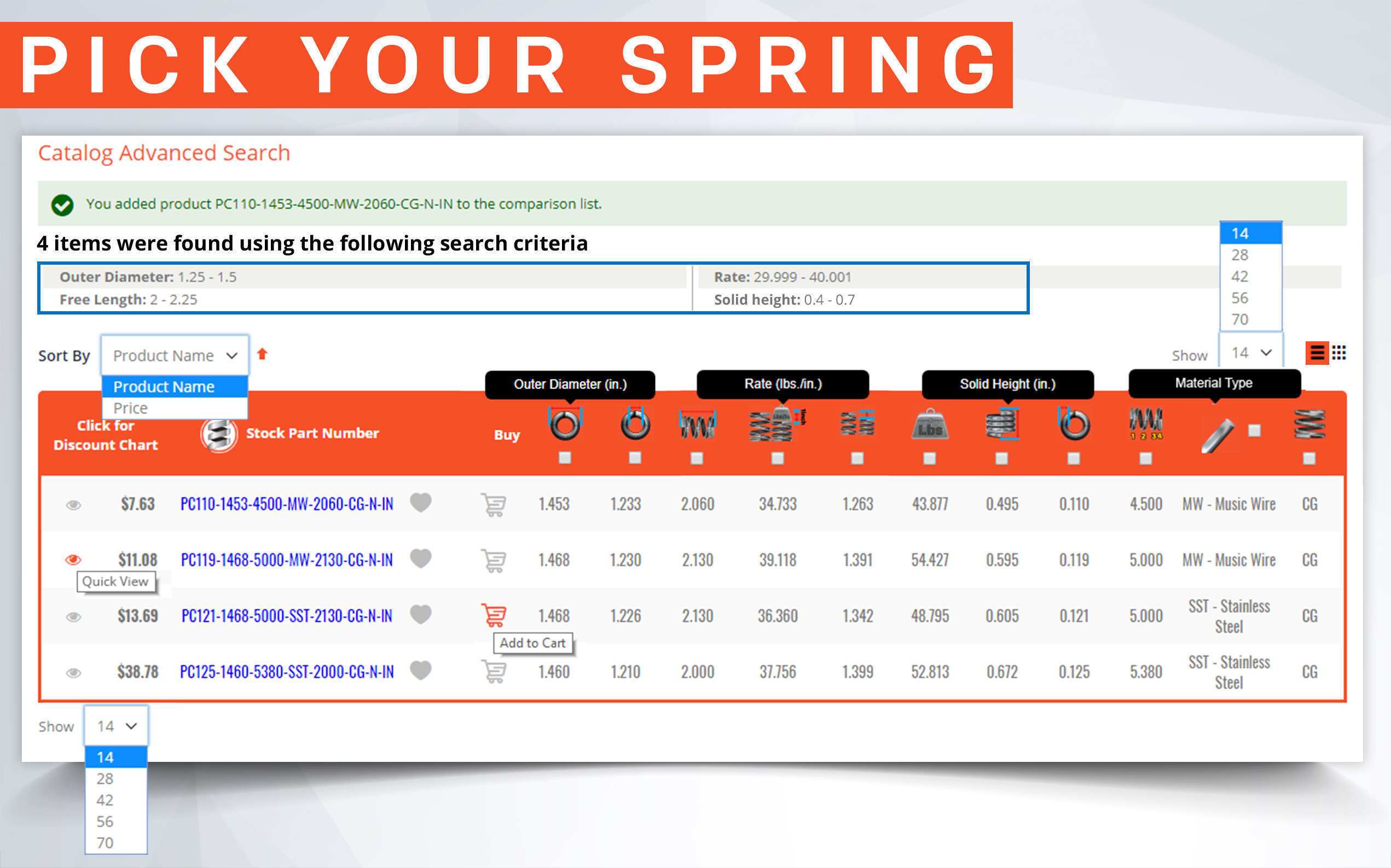

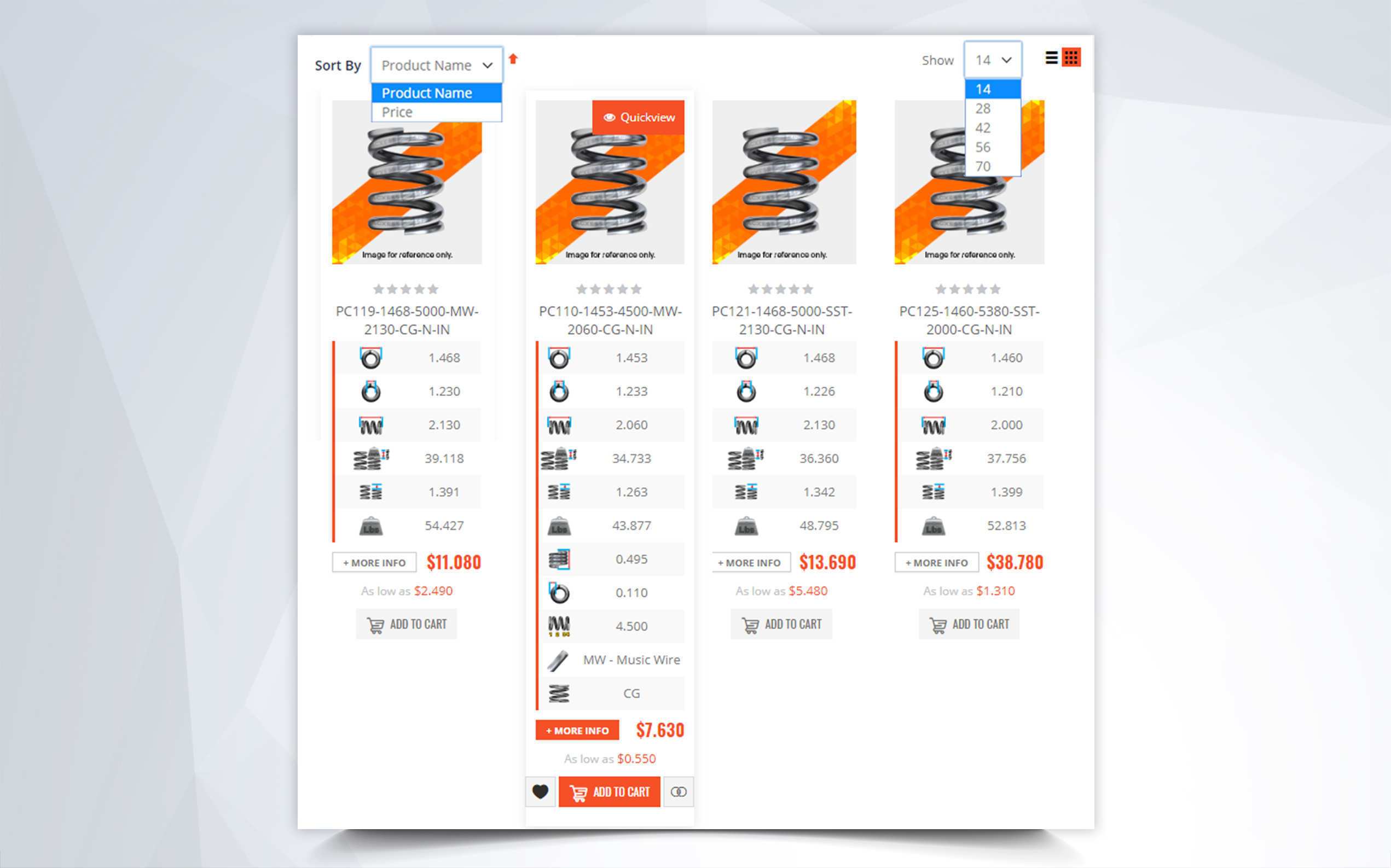

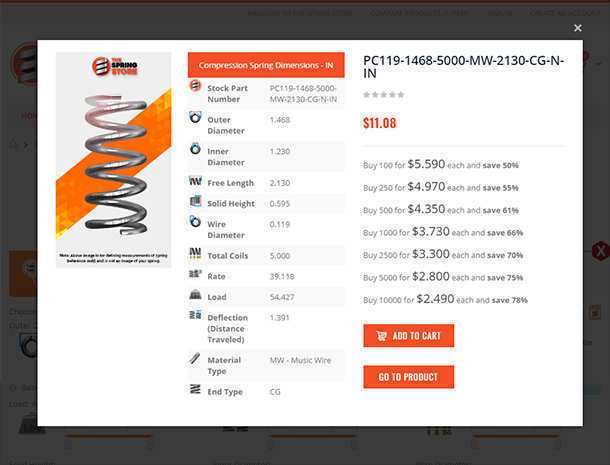

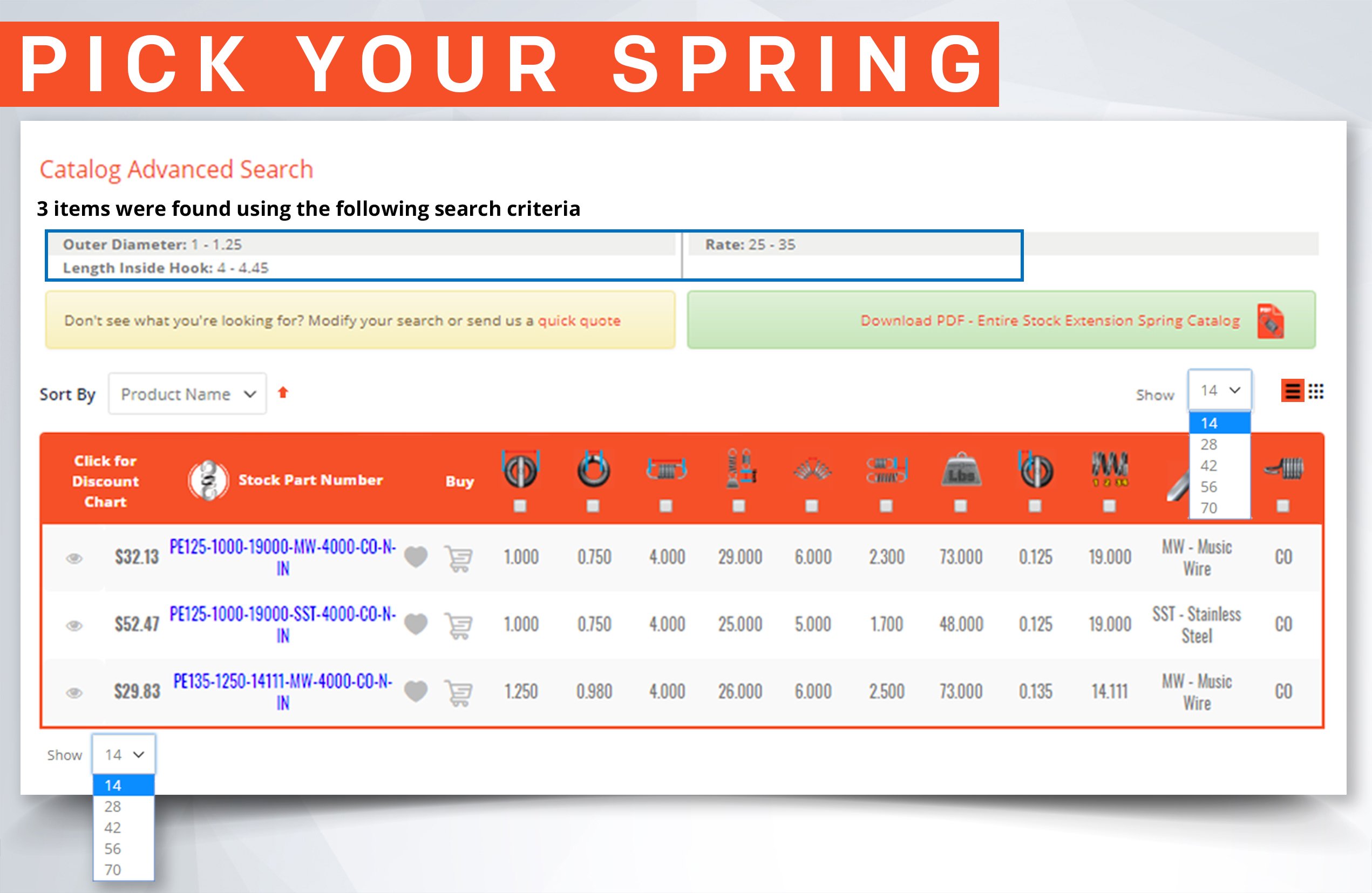

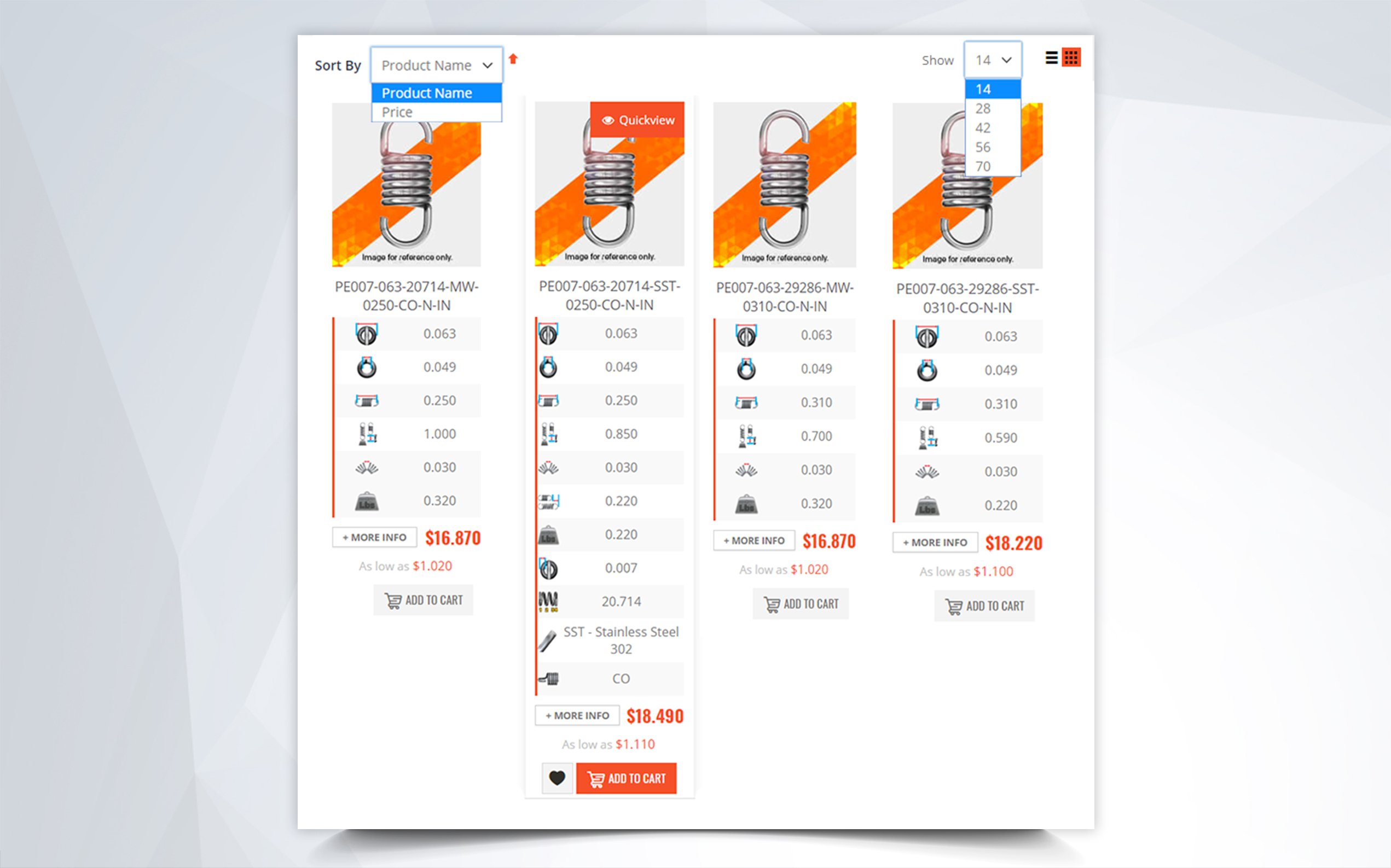

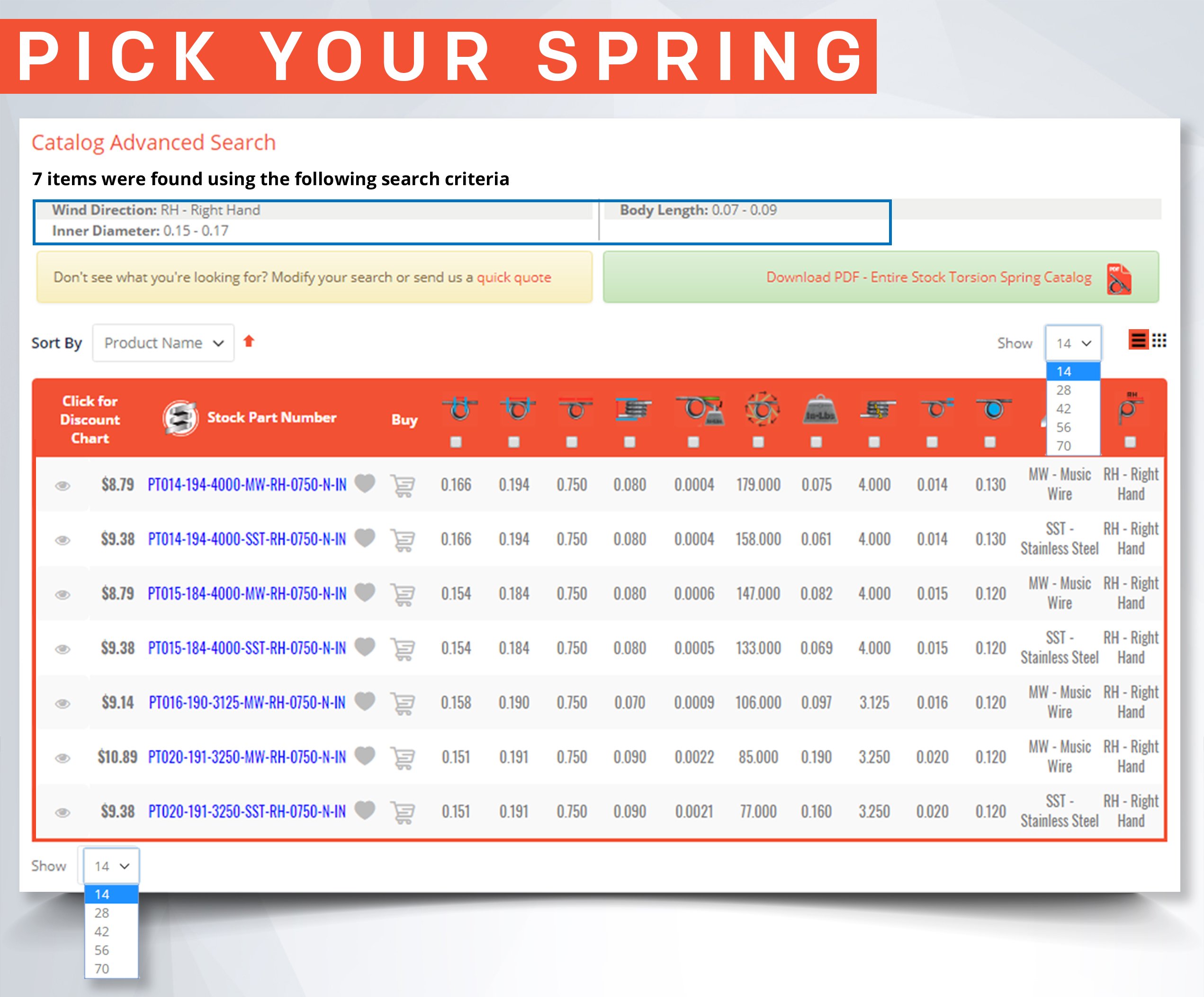

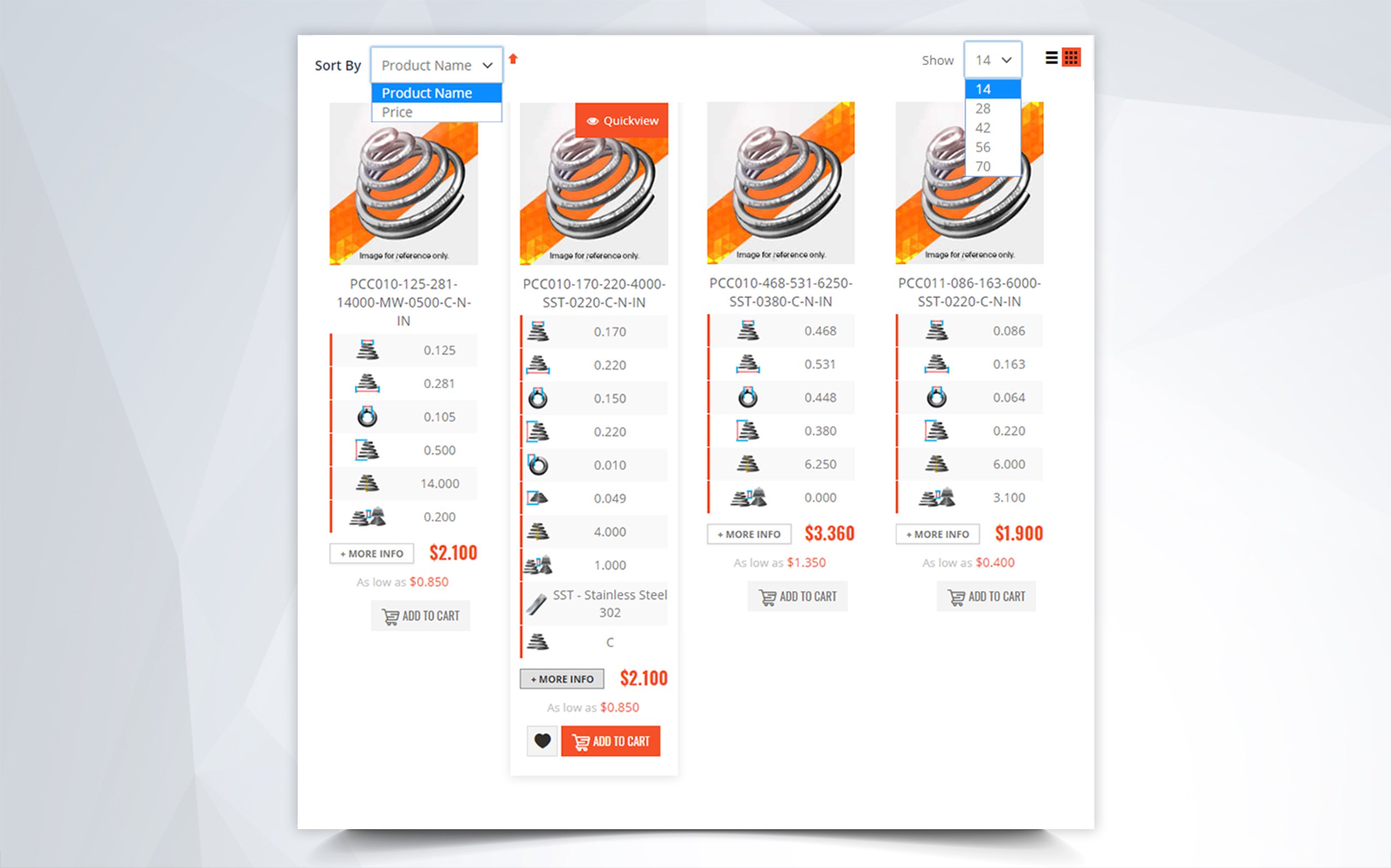

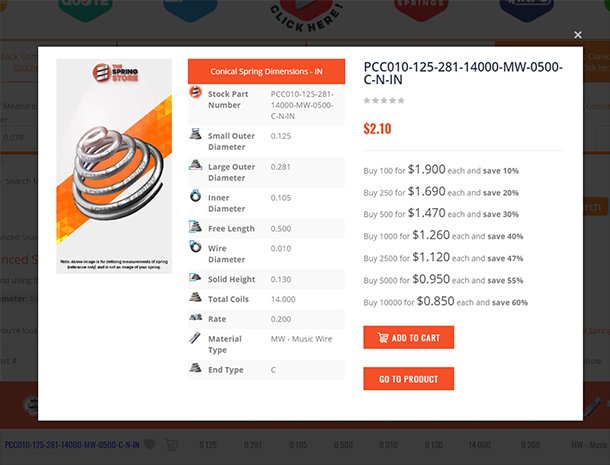

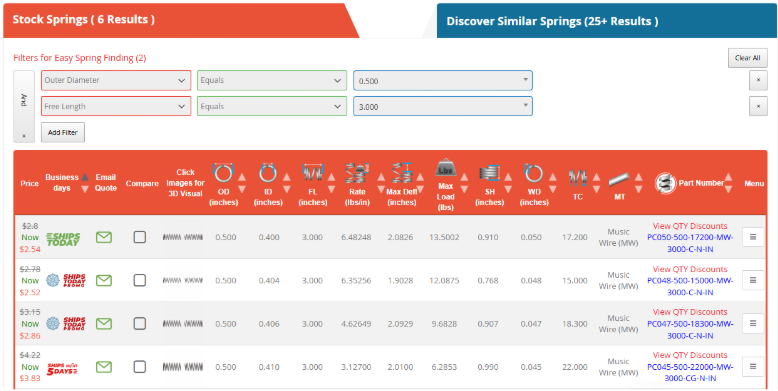

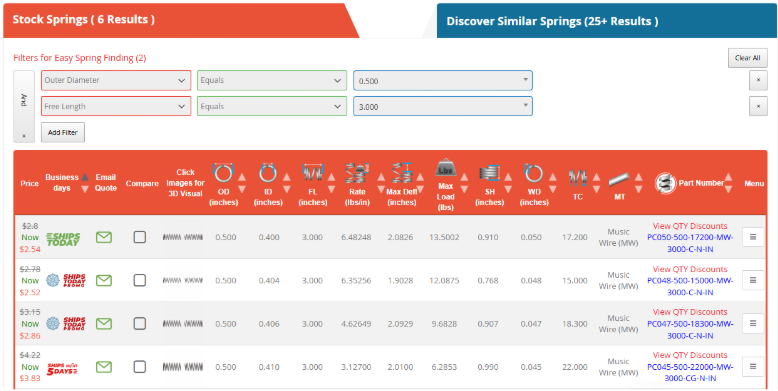

Step 3: Analyze the Results

Spring Finder 5.0 will provide a list of matching springs. Use filters to narrow down the options by specifications like spring rate, material type, or load capacity. In this search, we’ll use the filter for Free Length and Outer diameter, the two dimensions that are required.

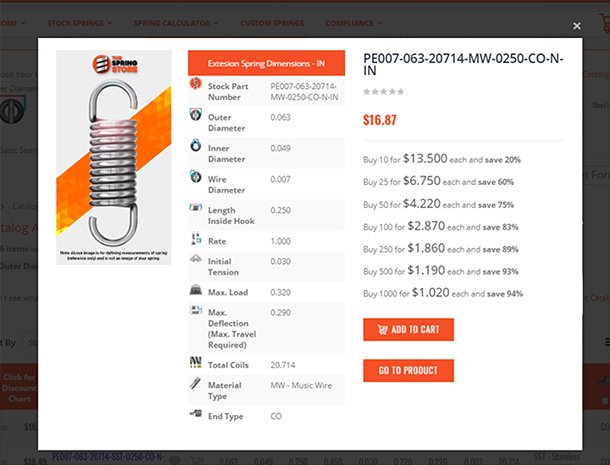

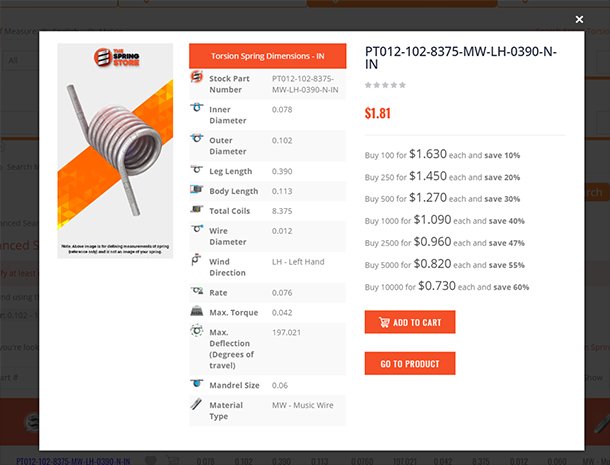

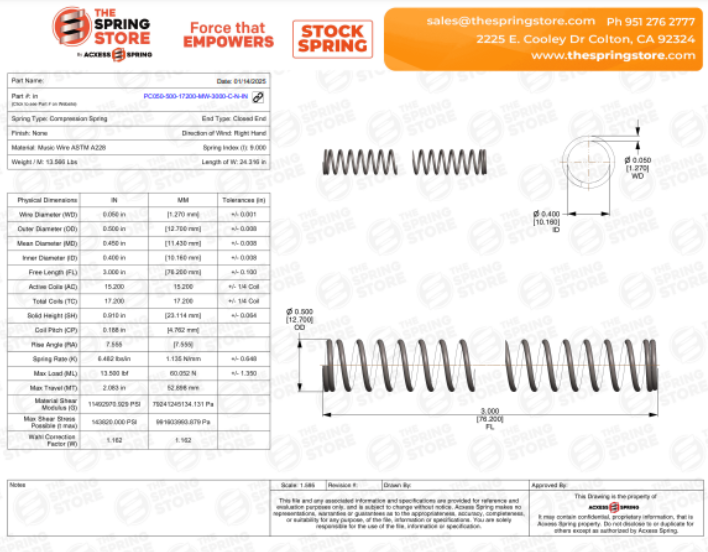

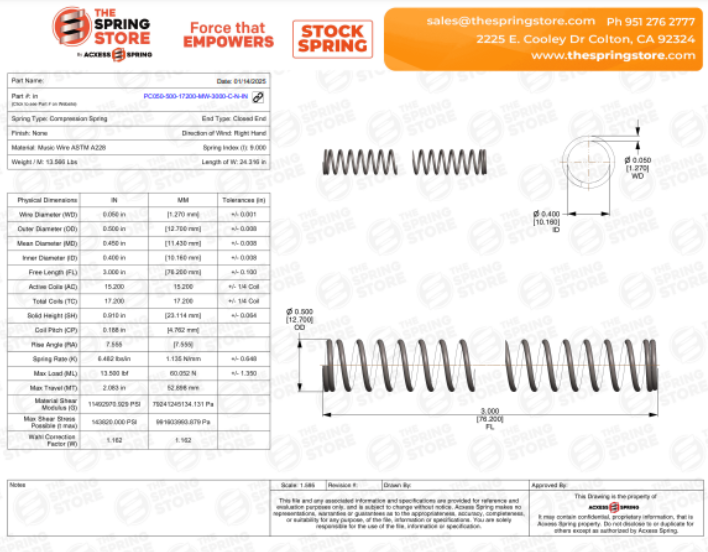

You can choose Acxess Spring Stock Part Number PC050-500-17200-MW-3000-C-N-IN that matches our requirements and offers shipping on the same day if you place the order before noon.

Step 4: Download CAD Models

Once you find the ideal spring, download its CAD model to integrate it into your design software for testing. This step ensures it’s a perfect fit before purchasing.

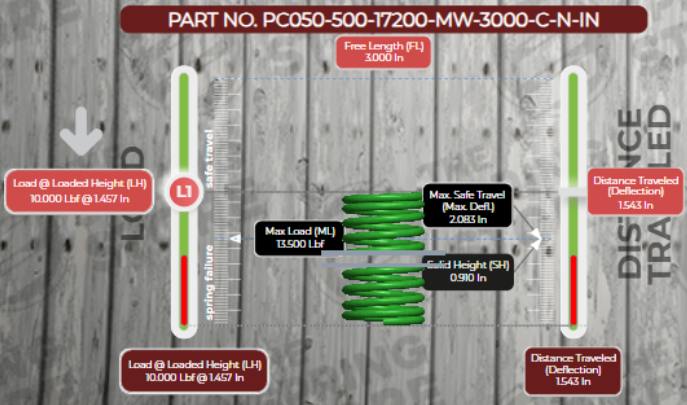

Step 5: Test with the Online Spring Force Tester (OSFT)

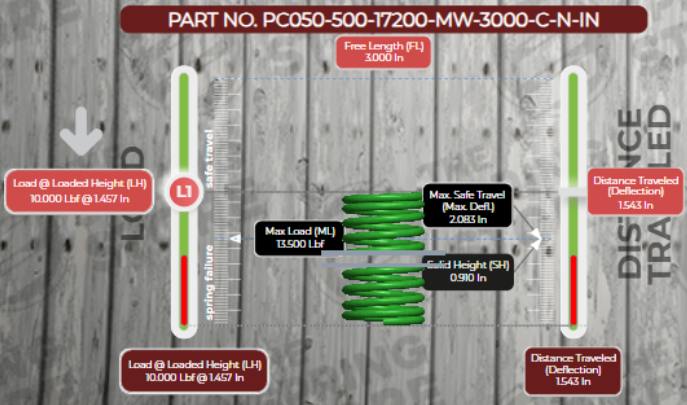

Use the OSFT to simulate the spring’s behavior under the required load. This helps confirm it will meet your needs before committing. Let’s remember that we need to test a 10 lbf load at a distance traveled of around 1.5 inches.

Step 6: Request a Quote

If everything checks out you can purchase online or request an instant quote for your selected spring. You’ll also receive a detailed blueprint to keep for your records.

Spring Finder 5.0 simplifies the entire process, offering options for both stock and custom springs. Whether you’re in a hurry or need something specific, this tool has you covered.

Key Takeaways for Success

Replacing a spring might seem tricky, but it’s easier than you think with the right knowledge and tools. Here’s a quick recap to make sure you’re on track:

Five Key Takeaways:

- Know Your Specs: Get the dimensions, rate, and material right for a perfect fit. Measure carefully and double-check before buying.

- Use Smart Tools: Tools like the Spring Finder and Online Spring Force Tester simplify the process and save time.

- Match the Spring to the Job: Make sure it’s built to handle the load and environment it will be used in.

- Choose Quality Materials: Durable materials mean a longer-lasting spring that performs reliably.

- Plan Ahead: Keep a stock of a few springs for quick replacements, so you’re never caught off guard.

The Spring Store makes it easy to find what you need. With over 42,000 options—from small springs to heavy-duty spring—you’ll have your device back in action in no time!